ROOM 22

ELIAS HOWE AND THE INVENTION OF THE SEWING MACHINE

EXTRACT FROM

GREAT INVENTORS AND THEIR INVENTIONS

PART 2

INVENTIONS OF MANUFACTURE AND PRODUCTION

by Frank Puterbaugh Bachman

1918

Sewing is older than spinning or weaving. Savages learned at an early time how to sew together pieces of fur. They used a pointed bone or a thorn to make a hole; through this they pushed a coarse thread or leather thong, making a knot at each hole. It took thousands of years for sewing to get beyond the shoemaker's way of doing it. Women learned, to be sure, how to make different stitches, such as the plain seam and the hem. Fine spun thread took the place of coarse twist and the leather thong. The bone needle with an eye at one end and a point at the other gave way to delicate steel needles. Still, sewing continued to be done by hand, stitch after stitch, first one, then another, hour after hour. Even up to the days of our own grandmothers, the family sewing continued to be the burden of the home. Men in England, France and America worked for years to relieve the home of this drudgery. Machine after machine was invented, but each of these was a failure. Not until 1846, did an inventor succeed in doing for the sewing machine what Watt did for the steam engine, Stephenson for the locomotive and Fulton for the steamboat. The inventor was Elias Howe, who was born at Spencer, Massachusetts, in 1819.

HIS EARLY TRAINING

Howe's father was a farmer, who, in addition to his farm, had a gristmill, a sawmill and a shingle machine. To the farm at Spencer, the neighbors brought their wheat and corn to be ground into flour and meal and their logs to be sawed into lumber or split into shingles. Yet with all his labor, the income of the father was small and supplied only a modest living to a family of eight children. In the pleasant surroundings of this New England farm, Elias Howe spent his childhood. Many were the rambles through the near-by woods for squirrels and nuts. The brook running through the farm afforded good swimming and fishing in the summer and good skating in the winter. When he was old enough, the boy did all sorts of simple farm work and helped at odd jobs about the mills and shingle machine. Each winter found him in the district school. Elias thus grew up, a happy, good-natured, play-loving boy. If his chances to obtain an education at the district school were not very good, this lack was made up, at least in part, by the opportunities he had to see and know trees, plants and animals and by being able to learn how to do things with his hands and to become acquainted with tools.

BECOMES A MECHANIC

The father's first thought was to make Elias a farmer. At eleven years of age the boy was apprenticed, as was the custom of the day, to a neighbor, where he was to live and work until he was twenty-one. Elias was not strong, having a lame foot. This made farm work hard for him. After trying it for a year, he decided to give it up. Returning home he went to work in his father's mills, where he remained until he was sixteen. About this time a friend of Elias's came back to Spencer from Lowell, Massachusetts. He told what a big and busy place Lowell was and how Elias could get employment there and earn more money and earn it more easily than at Spencer. Elias's ambition was thus stirred to go to Lowell and become a mechanic. It was not his liking for machinery that led him to go; it was the thought that a mechanic makes his living at easy work. Elias was not a lazy boy, but hard work so taxed his strength as to be very distressing to him. It was thus natural for him to want to avoid physical labor. His physical weakness led him also to do much thinking about how to do things with the least possible labor. At Lowell, Elias was taken on as a learner in a factory for making cotton machinery. Here he worked for two years, when the factory shut down. Drifting to Cambridge he found, after a few months, a place much to his liking, with Ari Davis, who kept a shop for making and repairing watches, clocks, surveying instruments and the like. Besides, his head was full of ideas of great machines. To hear him talk, it seemed not at all difficult to make a profitable invention. Naturally almost every workman in his shop had the inventor's bee. Still, Ari Davis's shop was not a bad place for a young country boy to be in and it was here that Elias Howe gained the suggestion which led to the invention of the first successful sewing machine. One day in the year 1839, a man came to the shop who was working to perfect a knitting machine. He was at his wit's ends and brought the model to Davis to see if he could help him. Davis in his extravagant way said:

"What are you bothering yourself with a knitting machine for? Why don't you make a sewing machine?" "I wish I could", replied the caller, "but it can't be done". "Oh, yes, it can", said Davis. "I can make a sewing machine myself". "Well", said the other, "you do it and you will have a fortune".

These remarks were taken by most of the workmen as idle boasts. Not so with Howe. He kept brooding over the idea of "inventing a sewing machine and making a fortune". As the boy brooded, this resolution slowly took form in his mind: "I will invent that sewing machine and win that fortune".

THE FIRST SEWING MACHINE

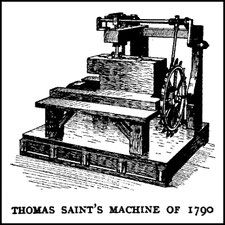

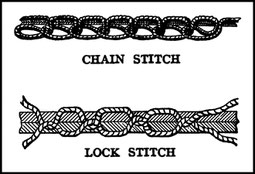

To Howe, a country boy just turning twenty, the idea of a sewing machine was new, but the idea was not new to the world. As early as 1790, Thomas Saint, an Englishman, took out a patent on a machine for quilting, stitching and sewing and for making shoes and other articles. Saint's machine had some of the features of good sewing machines to-day. Notice the overhanging arm and the block-like plate on which to place the material to be sewed. The machine had an awl, to punch a hole in the goods. A needle, blunt and notched at the end, pushed a thread through the hole to form a loop on the under side of the material. Through this loop the needle, on next descending, passed a second loop to form a chain or crochet stitch. There was also a feed to move the goods along under the needle, a continuous thread and stitch tighteners. It is probable that by the time Saint finished his machine and secured his patent, he was too much discouraged to go on with it. It may be, too, that to make a living he had to take up other work and before he got back to his invention, he became sick and died. Whatever the reason, for almost sixty years his machine lay unknown in the English patent office. The result was that scores of would-be inventors worked on sewing machines, only to miss the good points in his invention. When it was finally brought to light, people looked at Saint's machine with amazement and wondered how so great an invention could have been so completely forgotten.

The chain stitch made by Saint's machine has one drawback. When a break in the thread is followed by a slight pull, the chain stitch unravels. This does not occur with the lock stitch. The lock stitch is made by two threads. These are interlaced in the middle of the fabric sewn, so as to form a neat stitch on both sides of the fabric. The first sewing machine to make a lock stitch was invented by Walter Hunt of New York, about 1832. His machine had a curved needle with an eye at the point. The needle pierced the goods and at the moment when it started out, a loop was formed in the thread; at that very same instant, a shuttle carrying a second thread passed through the loop, making the lock stitch. Hunt was a gifted inventor. But either he thought little of his sewing machine, or he had other inventions which he thought promised greater and quicker profits. At any rate, he did not take the trouble to patent his machine and proceeded to sell the model to a blacksmith for one hundred dollars. Even the blacksmith, after he had bought and paid for the model, made no use of it. Some twenty years afterwards, when Howe's lock stitch machine became famous, this old discarded model was dug out of a rubbish heap and application was entered for a patent. The patent was denied. Hunt, like Trevithick before him, just failed to win one of the big industrial prizes of the century.

MAKING HIS FIRST SEWING MACHINE

It is often said that great inventions are a growth. This is true only when the would-be inventor makes use of what others before him have done. The idea of a sewing machine was not only new to Howe, but he did not know until many years afterwards that Saint, or Hunt, or any one of a score of others in England, France and America had ever made a sewing machine. So far as Howe knew, he was the first one in all the world who set out to make such a machine. So instead of trying to improve on what others before him had done, he went to work and created a new kind of machine altogether. For this reason, Howe's first sewing machine cannot be called a growth. When Howe first got the idea of inventing a sewing machine, he probably did a lot of thinking, during his leisure hours, about how such a machine could be made. But to take his regular turn at Ari Davis's shop called for all the strength he had. It was not long before he gave up active work on his invention, saying to himself, "Some day, I will invent a sewing machine". This became Howe's daydream. But it was not to remain a daydream. In 1840 Howe married and in time three children were born. His wages were only nine dollars a week. Nine dollars a week was all too little to house, feed and clothe a family of five. Besides, Howe's work was so hard that he often came home too tired to eat. He would go to bed, longing to lie there "forever and forever". Moved to act by the pinch of poverty and by the desire to escape the distressing fatigue of labor, he began to think once more about the machine which he had heard four years before would bring to its inventor a fortune. Then it was, about 1843, that the inventor's mania seized him and gave him neither rest nor peace until he had made a sewing machine. For almost a year, Howe, working evenings, tried to make a machine which would imitate the motions of his wife's hands, when sewing and make a stitch such as she made. Every attempt to do this failed. One evening in the autumn of 1844, Howe sat brooding over his last attempt when there flashed into his mind this question: "Could there be another stitch which would do just as well as the stitch made by hand"? This question set Howe on a new track. He was familiar with the chain or crochet stitch, from long watching his wife sew. From working in machine shops, he also knew about shuttles and looms.

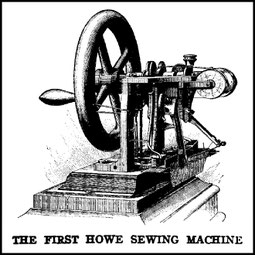

Soon he had an idea. It was short work to snap the point off of one of his wife's sewing needles and sharpen the head, thus making a needle with an eye at the point. With this he thrust the thread through two pieces of cloth to make a loop. With another needle he passed a second thread through the loop and gently pulled the two threads to tighten the stitch. A half dozen lock stitches were thus quickly made. But would such stitches hold? Howe was so anxious he scarcely had courage to find out. On trying to pull the pieces of cloth apart, to his great relief he found that this new kind of stitch held even tighter than the common hand stitch. It was easy enough to see how to make a machine to sew such stitches. But Howe had no money to buy the materials and no money to support his family while making the model, which, if it was to be successful, must be made with as much care as a clock. There lived at this time at Cambridge, an old friend and schoolmate of Howe's by the name of George Fisher, who had shortly before this time inherited a little money. Howe interested him in the invention. Fisher promised, for a half interest, to board Howe's family while he was making the machine and to advance five hundred dollars for tools and materials. Fisher said afterwards: "I was the only one of his neighbors and friends . . . who had any confidence in the success of the invention. Howe was looked upon as very visionary in undertaking anything of the kind and I was thought very foolish in assisting him". All through the winter of 1845, Howe toiled. He had the machine he wanted to make so vividly in mind that he worked almost as if he had a model before him. By May the first machine was complete and in July he did with it all the sewing on two suits of woolen clothes, one suit for himself and one for Mr. Fisher. Howe's model was a strange-looking sewing machine. Every part has been improved and many new ones have been added, but every one of the millions of sewing machines made since, owes at least one essential part to this machine, built in 1845. The way it sews is simple enough. The curved needle, with an eye at the point, carries the thread through the cloth and the loop of the needle thread is locked by a thread passed through this loop by the shuttle. The materials are hung on the pins of the baster plate, which carries the goods along in front of the needle. The baster plate was the weakest part of the machine. The seam that could be made without stopping was short and only straight seams could be sewed.

EXHIBITING THE MACHINE

The model was no sooner complete than off Howe carried it to one of the clothing shops of Cambridge. He offered to sew any kind of garment brought to him. The incredulous tailors and seamstresses brought shirts, waists, skirts and trousers and were amazed to see the seams sewed perfectly, at the rate of two hundred and fifty stitches a minute, which is about seven times as fast as handwork. For two whole weeks, he sewed seams for all comers. Finally he challenged five of the fastest seamstresses in the shop to a sewing contest. Ten seams of equal length were laid out. One seam was given to each of the five seamstresses and five seams to Howe. Howe was through first and besides, the umpire of the contest, a tailor, said that the work done on the machine was the neatest and the strongest. One might suppose that Howe would at once have been flooded with requests for machines. But not one tailor, nor a single individual customer came forward with an order. Nor did Fisher and Howe have any better success at Washington, in the summer of 1846, where they went to take a model and secure a patent. While there, they exhibited the machine at a fair. They had an enjoyable time and heard "Ah's!" and "Oh's!" on all sides, but not one voice was heard by their anxious ears, asking to buy or even to rent a machine. Fisher was now discouraged. The machine had been known to the public for more than a year and not a single one had been sold. He had boarded Howe and his family for almost two years, besides advancing in all about two thousand dollars. "I lost confidence", said Fisher, "in the machine's ever paying anything".

OFFERING THE MACHINE TO ENGLAND

Howe was not to give up so easily. Borrowing money from his father, he sent his brother Amasa to England, to see what could be done there. The first man to buy one of Howe's machines was William Thomas, of London. Thomas had a large factory in which he made corsets, carpetbags and shoes. Seeing the value of the machine for his business, he bought the one Amasa had with him, for twelve hundred and fifty dollars. This was a poor bargain, because it also included the right to use as many other machines as Thomas might need. Thomas was to get also an English patent on the invention, promising to pay the inventor a royalty of fifteen dollars on each machine sold in England. Thomas patented the invention, but later refused to pay the promised royalty. By his foresight, along with his dishonesty, Thomas probably made on his investment of twelve hundred and fifty dollars, a net profit of a million dollars. Howe still saw no prospect of making anything in America, so when Thomas offered him fifteen dollars a week, if he would go to England and adapt his machine to corset making and the like, he accepted. He set sail early in 1847, going in the steerage and cooking his own food. A little later he sent for his wife and children. For some eight months Howe worked to adjust his machine to the needs of Thomas's business. During all this time, Thomas treated him with respect. But when the work was done, Thomas made it so unpleasant that Howe had to give up his position. This left him a stranger in London, without work and with a sick wife and three children to care for. He had little money, but he undertook to make a fourth machine, hoping against hope that he could sell it at a good price. From Charles Inglis, a coachmaker, Howe rented a small shop and with such tools as he could borrow went to work. Long before the machine was finished, his money ran low. To reduce expenses, he moved his family from a three-room apartment to one room and this in the poorest section of London. Fearful that he might not be able to get his family back to America, he decided to send them while he still had the money, trusting that he could follow when the machine was finished and sold. Before his wife left London, said Inglis, who proved a friend in time of need, Howe had frequently borrowed money from me in sums of twenty-five dollars and requested me to get him credit for provisions. On the evening of Mrs. Howe's departure, the night was very wet and stormy and her health being delicate she was unable to walk to the ship. He had no money to pay cab hire and he borrowed it from me. He repaid it by pawning some of his clothing. Alone and without money, Howe had scarcely enough to eat to keep him alive. He has borrowed a quarter from me, says Inglis, for the purpose of buying beans, which I saw him cook and eat in his own room. The finished machine was worth at the very least two hundred and fifty dollars. But the only customer Howe could find was a workman, who offered him twenty-five dollars, providing he could have time in which to pay it. No one else wanting the machine at any price, Howe was obliged to accept this offer. The purchaser gave his note for twenty-five dollars and Inglis succeeded in selling the note to another workman for twenty dollars. The small sum of twenty dollars was thus Howe's return for some four or five months of toil and humiliation. To pay his debts and secure passage home, he was compelled to pawn his precious first machine and his letters of patent. Even then he had so little money that, to save cartage, he borrowed a handcart and hauled his own baggage to the ship. Howe landed at New York in April, 1849. Four years had come and gone since the completion of the first machine. The one lone fifty-cent piece in his pocket was the only visible reward for these years of anxiety and toil. Yet Howe was happy. He heard that there was plenty of work in New York and within a few hours he had a position as a mechanic in a machine shop. A few days after this, news came that his wife was dying of consumption. He had no money to make the trip to Cambridge and could not go, until his father, ever loyal, sent him the needed ten dollars. Howe arrived at his wife's bedside just in time to see her alive. The only clothes he had were the working clothes he wore and to appear at her funeral he borrowed a suit of his brother-in-law. Under such trials and humiliations Howe aged rapidly and he looked like a man who had been through a severe illness. But he was once more among friends. They did not think much of his invention, but they loved the man. His children were being cared for and soon he was hard at work again, not on his machine, but as a mechanic at a regular wage.

FIGHTING FOR HIS RIGHTS

If money was not to be made out of the sewing machine as a useful invention, there were persons who thought that money could be made out of it as a curiosity.

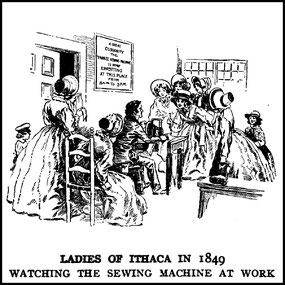

On the streets of Ithaca, New York, in May, 1849 ?? (Scientific American May 6, 1848), you might have seen this show bill:

A GREAT CURIOSITY

THE YANKEE SEWING MACHINE

IS NOW EXHIBITING AT THIS PLACE

FROM 8 AM TO 5 PM

People came in numbers to see the new wonder and women carried home samples of sewing as souvenirs. This advertising led a few persons to want machines. Mechanics, especially in Boston, began to make and sell them. But this was not all. Other inventors entered the field. Among these was Isaac M. Singer, who added a number of practical parts and who did most to bring the sewing machine before the public. Singer's interest in the sewing machine was aroused in the summer of 1850, while on a business trip to Boston. In the shop of a Mr. Phelps he saw a crude machine patterned after Howe's model at Washington. Noting Singer's interest, Phelps remarked: "If the sewing machine could be made to do a greater variety of work, it would be a good thing". Howe's machine, you know, sewed only a straight seam. During the evening, at his hotel, Singer worked out the drawings for a number of changes. The next morning he showed a rough sketch of the proposed machine to Phelps and to a Mr. Zieber. They were satisfied that it would work. But Singer had no money to make a machine. Zieber proposed to advance forty dollars for the purpose and Phelps offered to make the model in his shop. Work on the model started that very day. "I worked at it day and night", said Singer long afterwards, sleeping but three or four hours out of the twenty-four and eating generally but once a day, as I knew I must make it for the forty dollars, or not get it at all.

The machine was completed in eleven days. At about nine o'clock in the evening we got the parts together and tried it. It did not sew. The workmen, exhausted with almost unremitting work, pronounced it a failure and left me, one by one. Zieber held the lamp and I continued to try the machine, but anxiety and incessant work had made me nervous and I could not get tight stitches. Sick at heart, at about midnight we started for our hotel. On the way, we sat down on a pile of boards and Zieber mentioned that the loose loops of thread were on the upper side of the cloth. It flashed upon me that we had forgotten to adjust the tension on the needle thread. We went back, adjusted the tension, tried the machine, sewed five stitches perfectly and the thread snapped. But that was enough. Thus in the course of eleven days, Singer, working at white heat, made over Howe's machine and added new features. Among these are the overhanging arms, the spring foot near the needle and the double-acting treadle. By 1851, he had his machine ready for the market. If Mr. Singer was not a great inventor, he was skillful in making practical the ideas of others and he was a great business man. He, more than anyone else, aroused the world to the value of the sewing machine. He did this through advertising. He used posters, pamphlets, almanacs and newspapers, to tell of the worth of the new invention. Sewing machine shows were held in towns and cities; there were bands to attract the people and skillful young ladies to exhibit the wonderful work of the new marvel. Sewing contests were arranged and prizes were given to the speediest and best sewers. Local agents were employed and these agents, with their wagons loaded with machines, went everywhere. No wonder that a man as modern in his methods as Singer made a fortune and that he was the founder of the greatest sewing-machine company in the world to-day. To return to Howe. As Howe worked away at a mechanic's wage, he learned that sewing machines were being exhibited in different parts of the country as curiosities and that persons were making and selling them. He examined some of these and found that they were either made after his model at Washington, or embodied the essential parts of his machine. But never a word was said about his being the inventor. To secure his rights, as well as the reward for his labor, nothing remained but to take the matter to the courts. Howe had no means, but he succeeded in interesting a man of wealth, who bought Mr. Fisher's half interest in the patent and also advanced money to prosecute the infringers. The new partner, however, did not want to lose any money on the venture. To protect himself against loss, he demanded a mortgage on the farm of Howe's father. The father, faithful to the end, consented. Suits in court, then as now, went forward slowly and Howe had time for other things. We find him in New York in 1850, making and selling fourteen of his machines. A few of those who had also been making and selling machines, fearful of the consequences, secured licenses from Howe and this added a little to his income. But Howe was busy chiefly, during the years 1850-1854, with his different cases in the courts. Singer, the chief infringer, contested Howe's rights the hardest. To show that Howe was not the inventor of the sewing machine, the inventions of Saint, Hunt and many others were brought into court. Finally, in 1854, a verdict was rendered which gave Howe the victory. The judge found Howe's patent valid and declared:

"There is no evidence . . . that leaves the shadow of a doubt, that, for all the benefits conferred on the public by the invention of the sewing machine, the public is indebted to Mr. Howe."

REAPING THE REWARD

In the meantime, the new partner had died. His heirs having no faith in the future of the sewing machine, sold their share to Howe at a low price. For the first time he was the sole owner of his invention. Fortune was at last on his side. The public began to appreciate the sewing machine and suddenly a great demand arose for them. Howe received a royalty on all of whatever kind made in the United States, no matter where they were sold. A perfect flood of gold soon poured in upon him. In a very few years his income leaped from three hundred dollars to two hundred thousand dollars a year. In all he received about two million dollars in royalties, or approximately a hundred thousand a year, for the twenty years of his life devoted to his invention. In return for this he gave an invention, which, as it has improved, has lessened the work and added to the comfort of almost every home in the civilized world; for sewing machines are to-day found alike in the jungles of the Amazon and on the heights of the Himalayas. His invention has given birth also to new industries, such as the making of ready-made clothing. So enormous has this business become that single factories using hundreds of power machines and employing thousands of women, turn out but one kind of article, such as frocks for girls or suits for boys. And it has given new life to more than half a hundred old trades, such as the making of straw hats, shoes and harness. Even the manufacture and sale of sewing machines has in itself become a giant industry. If Howe's reward for his toil and anxiety was great, great also was his gift to the world.

by

Frank Puterbaugh Bachman

1918

As reproduction of historical newspaper articles and/or historical sources and/or historical artifacts, this works may contain errors of spelling and/or missing words and/or missing pages and/or poor pictures, etc.

Fiddlebase

Fiddlebase