- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

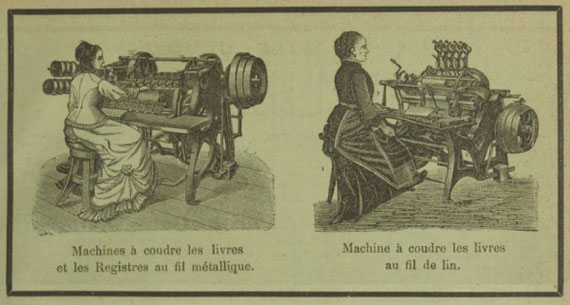

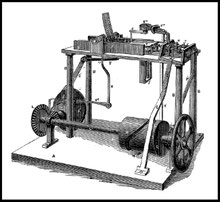

BOOK-SEWING MACHINES

A bit of history

In the craft period of book-making, printed sheets were folded, pressed, stacked in a sewing frame and sewn by hand through the fold of each gathering onto cords or tapes. Pamphlets were often stab stitched through the sides rather than the spine.

In 1867 one of the earliest book-sewing machine was patented in America. The inventor Ferdinand Sims, from Texas obtained patent US 66.899.

In 1868, two British Letters patents were issued for book-sewing machines . One patent GB 1.604 to Mr. Henry Graham Thompson, of New York and the second patent GB 1.539 to Amos Holbrook Jr. of Massachusetts. This machine was full described and illustrated on front page by the English Mechanic and Mirror of Science. According to The Sewing Machine Gazette, June 1895, probably this two book-sewing machines never went into production.

In 1871, in England and probably in the rest of Europe, did not exist a single book-sewing machine; practical mechanics in the sewing machine trade will admit on examining a hand-sewn book that its production by machinery means a stupendous amount of inventive skill.

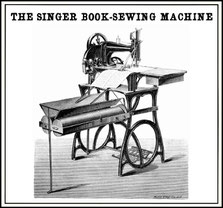

In 1873 Mr. Charles H. Palmer invents a new book-sewing machine, based on the familiar sewing machine known as Singer's.

The machine, with an additional mechanism and properly manipulating the single signature of a book or a pamphlet of moderate thickness, so that it could be perforated at one stroke by a suitable needle, allowed the sewing to be properly effected. The Pamphlet Stitching-Machine Company of New York was the patent, US 135.662, assignee.

In 1874 Henry Graham Thompson, obtained British patent GB 1.000 on the 21st day of March.

In 1875, James Armstrong using an ordinary sewing machine tried to solve those obstacle in sewing books. His machine by the use of a rotary drill, enabled him to make the holes with ease, precision and rapidity through any thickness used in pamphlet or signature form; also, his book-sewing machine solved that great obstacle in feeding the book or signature fast enough, so as to enable long stitches to be taken.

In 1876 George W. Glazier in his patent US 184.961, stated that: ...in a machine invented before mine, by David M. Smyth, there were semicircular needles passing into the notches of the folded sheet...*

In 1876 the Singer Manufacturing Company adapted the principle of their sewing machine to the stitching of books and pamphlets and we publish herewith an engraving of the book-sewing machine, in which all the parts are represented with such clearness that little explanation is necessary. The sheets of printed paper are first folded and then passed into the machine in succession. The attachment for effecting this is shown in our illustration and it stitches the sheets, feeds them forward, cuts the thread and conducts the sheets along downwardly inclined guides, so that they fall between two rolls, which fold and smooth them. The machine is capable of stitching sheets of any size or thickness and how ever thickly the sheets may be folded, the rollers will give them the proper pressure, being united by an elastic connection which allows all thicknesses to pass through under their pressure. The machine stitches the sheets with great rapidity and as each sheet is stitched separately, the binder can get the sheets ready for binding as fast as they come from the printer, the sheets being afterwards collated for insertion in the covers. Much time is saved by this method, as every one familiar with bookbinding will acknowledge and the separate threads to the sheets insure elasticity to the back, which allows the book to open easily and so contributes in an important degree to the durability of the binding.

In 1877 in Germany, a Book-Sewing Machine, using wire, was patented by Augustus Brehmer. The Gebrüder Brehmer Company was founded in 1879 in the Plagwitz district of Leipzig by Hugo Brehmer, who had returned from America. In the United States, he and his brother August Brehmer contributed to the development of the wire stitching machine and introduced it to the German market. The "Brehmer" wire-sewing machine sews together the sections of books on tapes or crash (a coarse plain linen, woolen, or cotton fabric, used for curtains and towels). It is used for both printed and blank work and the manufacturers claim that it makes a strong book, which can be opened flat more easily than books sewed by hand.

In 1877-8, a device for bookbinders has been invented by Mr. Carl Theene, of Minden, Germany. It is a Book-Stitching Machine, constructed on the general principle of a shuttle sewing machine, with a needle lubricating apparatus attached to the presser bar and foot and a continuous feed and guide arrangement that is adjustable for the different sizes and thicknesses of books.

In 1879 David McConnell Smyth developed a new and improved book-sewing machine with curved needle that would have been of a great success.

"A machine that sews books perfectly and that is said to be destined to revolutionize the binding business has been invented, it is claimed, by David McConnell Smyth, of Hartford, Connecticut. The machine is about four feet high, three feet wide and two and a half feet deep and looks like an ordinary sewing machine. On a single bar are arranged eight semicircular needles, which enter with exactness and automatic regularity the incisions in the sheets, which are previously made in the common way. Passing ceaselessly in and out, these needles make a perfect lock-stitch, at the rate of from 25.000 to 30.000 signatures a day, whereas a girl who can sew 2.500 signatures per day by hand is considered an expert. A corporation, composed of well-known business men, has been formed at Hartford, with a capital of $300.000 for the manufacture of the machines".

In 1880 an improvement in book-binding has been patented by Mr. James W. Loveridge, of Jersey City, New Jersey. The object of this invention is to lighten the expense and labor of binding books by enabling the binder to stamp, gild, or print the covers and back at one operation. It consists in forming a book cover in one piece of a material of uniform thickness to allow the covers and back to be stamped, gilded, or printed at one operation and grooving the inner side of the back to give flexibility to the back of the book.

In 1885 at the London International Invention Exhibition, two book-sewing machines will obtain an Award. A Silver Medal to Augustus Brehmer for his thread book-sewing machine and a Bronze to Mr. F. R. Daldy who exhibited the Smyth's book thread sewing machines.

1887 Royal Jubilee Exhibition Manchester. Augustus Brehmer, 33 and 35, Moor-lane, London, E.C. This Exhibit is worked by John Heywo.

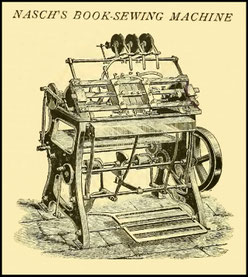

In 1891 Isidor Nasch, the son of a bookbinder, who left Germany and went to London with the intent on improving his position in life and now a sewing machine manufacturer and dealer, patented his improved machine for sewing together the sheets or signatures of books.

In 1894-5 Nasch went in partnership with Joseph Alexander Profumo, carrying on business as Manufacturers of Book-Sewing and Stitching Machines at 16, Barbican in the city of London under the firm of Nasch's Patent Book Sewing Machine Company.

In June 1895, The Sewing Machine Gazette will write about him as following:

"...We are thus able to announce that the absolute duplication of hand book-sewing by machinery is at last an accomplished fact and to add that the world owes the whole credit to a London sewing machine manufacturer..."

The partnership was dissolved from the 19th day of December 1895.

(*) notes:

I couldn't locate the patent that George W. Glazier was referring to.

Nowaday only few companies producing book-sewing machines are in existence, two in Italy, one in Switzerland and in India. (www.harbhajanstitcher.com)

SMYTH S.r.l. is a market leader in the design, planning and construction of bookbinding machines and in finding solutions for sewing and binding printed books in both off-set and digital versions, with a vertical focus on thread book sewing machines, gathering machines, back-gluing lines, case-makers and book finishing solutions also for short run books-on-demand. Smyth guarantees an excellent after-sales service for all its machines, vast technical know-how to support its Customers, continuous innovation and product quality recognised world-wide, with over 560 active customers in 65 countries spread over 5 continents. Everything is made in Italy at Smyth’s, from the design and planning stage to the production of every single component, with meticulous and fine hand finish that goes into every detail. The company has its headquarters in Casale Monferrato (AL). It was Smyth who invented the thread book sewing method which bears the Smyth name. From the end of the 1800s this method, recognized the world over as “Smyth Sewing”, has guaranteed high quality, strength and durability and stands as testament that our brand is synonymous with quality and dependability.

MECCANOTECNICA, located in Italy, is the world’s leading manufacturer of automatic book sewing equipment and lines for book finishing. Globally well, known thanks to its ASTER book sewing machines for OFFSET PRINT FINISHING, Meccanotecnica has entered the DIGITAL PRINT FINISHING market by developing new solutions to allow cost-effective binding of short runs and the production of high quality books.

MULLER MARTINI. As a pioneer of the graphic arts industry, Muller Martini’s top-quality print finishing systems enjoy global recognition. Muller Martini is an international, independent family business that has always identified market trends early ever since it was FOUNDED in 1946. Muller Martini’s highly automated machines are state of the art today. They come into their own in combination with smart connectivity and a seamless workflow. Under our Finishing 4.0 development strategy, we provide innovative solutions for the finishing of digital and offset printed products. With over 20 sales and service companies, 40 agencies and production sites in Switzerland, Germany, the USA and China, Muller Martini can rapidly provide on-site support on all continents. Our technically savvy sales and service professionals are among the leading consultants in the graphic arts industry and always strive for the optimal customer solution.