- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

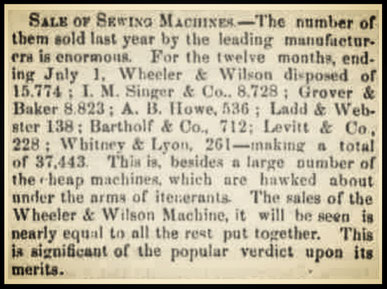

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

WHITNEY & LYON

c. 1854 - 1863

345 Broadway, New York

(later)

477 Broadway, New York

Manufactory:

Nashua, New Hampshire

(later)

Saint John, New Brunswick, Canada

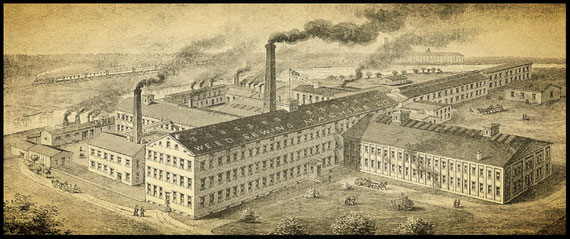

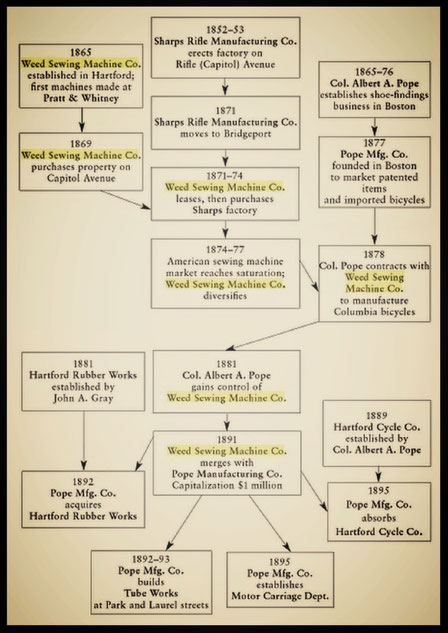

WEED SEWING MACHINE COMPANY

1863-1891

Offices: 506 Broadway, New YorK

239-240 Main Street, Hartford

Factory: College Street

POPE MANUFACTURING COMPANY

1878 - 1915

1881-1890 (Pope owned one-third of Weed)

1890-1891 (Weed controlled by Pope)

******************** CHRONOLOGY *********************

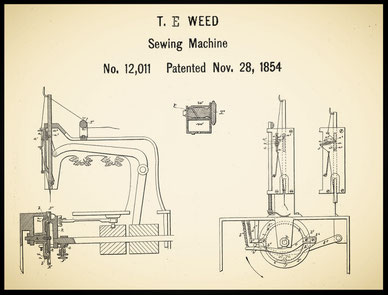

1854

WEED'S PATENT

Theodore E. Weed

US 12.011 November 28, 1854

1855

SALE AT AUCTION OF A

WEED'S PATENT SEWING MACHINE

May 8, 1855

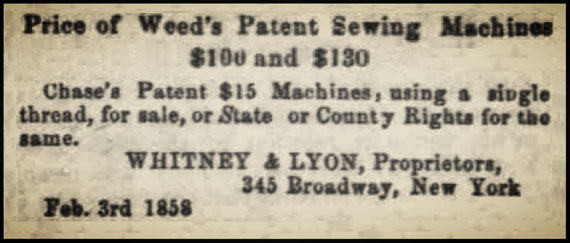

1858

WHITNEY & LYON, Proprietors

345 Broadway, New York

PRICE OF WEED'S PATENT SEWING MACHINES IN 1858

$ 100 and $ 130

1859

WHITNEY & LYON, Proprietors

477 Broadway, New York

Below, we give a description of the different styles of the Weed Patent:

No. 1. Is a very convenient style, which can be worked by hand or foot, on or off is own table. For convenience of shipping and also for large manufactories, where it is necessary to place a number of Machines into a long bench, making one table answer for them all. Price, $ 90.

No. 2. With Walnut or Mahogany Table, either with or without Box Top, which locks down. Price, $100 and $ 110.

No. 3. Same size as No. 2, but runs with a bell and at a much higher rate of speed. This kind is well adapted lo manufacturing Clothing or Leather work. This is really the cheapest Machine in the market and there is no work done on a Sewing Machine that it will not do. It is confidently asserted that this Machine runs easier than any machine now in use. Price, $ 100.

No. 4. This Machine has a long arm, to accommodate large work. It runs at a high rate of speed, runs easily and is, without a doubt, the best Machine for Tailors' use, ever offered to the public. It is also peculiarly fitted on plantation work, as it is very simple yet substantial and durable, with but little liability to get out of order. Price, $ 120.

No. 5. This is a new and cheaper style and a general favourite for Family, Light Leather and a great variety of work. It has been gotten up with reference to furnishing a strong and durable, yet light and lastly Machine, at a less price than either of the above. It runs very easy, rapidly and is pronounced the best machine now in market for $ 80.

No. 6. This is a Machine got up on an entirely new principle, different from anything ever before offered to the public.

It is very light and tasty and runs very rapidly, is almost noiseless in its operation and uses A STRAIGHT NEEDLE. It is so arranged as to be utterly impossible for it to miss stitches. It has a tension on both sides and carries a large supply of thread under the spool. The motions are gained by two small cranks than run without perceptible noise. The two threads are worked in such a manner as never both to pull at the same time and consequently little liable to break. The seam is very elastic and the thread does not break in washing. It will do coarse work better than any cheap machine now in market, as it use silk, cotton or linen with equal facility. Price, $ 50.

Also called : Weed's Patent Family Sewing Machine

1859

WHITNEY & LYON

477 Broadway, New York

1860

WEED'S PATENT SEWING MACHINE

1861

WEED'S PATENT SEWING MACHINE

1862

SALE AT AUCTION OF A

WEED'S PATENT SEWING MACHINE

1863

THE WEED SEWING MACHINE COMPANY

The original machine patented by Theodore E. Weed was made at Nashua, New Hampshire and later at Saint John, New Brunswick. Canada.

The company controlling the patents (first formed in West Winsted, Connecticut, Feb. 4, 1863) moved to Hartford in July, 1865 and reorganized with Jonathan S. Niles as president, George M. Welch as secretary and treasurer and George A. Fairfield as superintendent. A contract for building 15.000 machines was then placed with Pratt & Whitney Co., who were located in the "Woods" building, near the junction of Main and Grove streets.

It is quite probable that this order had a part in influencing the firm to erect a factory of their own during the year.

In May, 1886 (1866 or 1868), a second large contract for machines was entered into with the same parties, reinforced by George A. Fairfield and Charles E. Billings. Succeeding Mr. Niles, Homer Blanchard was president from 1867 to August, 1876; George A. Fairfield from August, 1876, to July, 1881; J. W. Beach from July, 1881, to 1887 and on the death of Mr. Beach, George H. Day, the treasurer, was elected president also.

In May, 1869, a part of the present property on Capitol Avenue (ex College Street) was purchased of E. M. Archibald, agent for the British government. Owing to the great popularity of the Weed machine and to the increasing volume of orders, Sharps' Rifle Factory adjoining was leased, in 1871, for a term of five years and purchased in 1874.

Sharps' Rifle factory was located in Rifle Avenue, a continuation of College Street eventually renamed Capitol Avenue.

According to my records, Pratt & Whitney factory was in Howard Street, west of Rifle Avenue, between Railways and Park River (The small river which once marked the limit of the two company's buildings now bisects the Pratt & Whitney Co.'s buildings.).

In 1870, Sharps and his family moved to Vernon, Connecticut, where he continued working on firearm designs and started a large trout farming business. Succumbing to tuberculosis, Sharps died in Vernon, on March 12, 1874. In all, he was awarded a total of fifteen firearms-related patents. "Sharps & Co." was shuttered after his death and firearms production came to an end. Although, "Sharps Rifle Co" continued to produce his namesake rifles until 1881, when it too closed its doors.

In the special line on which the company began, it has kept fully abreast of the times by the number and value of its improvements and inventions. While the name remains to perpetuate the fame of the founder, not a feature of the original machine is retained. The second combination of contrivances have largely followed the first, as will the present when anything better can be found to take their place. As a result of ceaseless efforts to produce the best, the demand from all quarters of the globe continues. Ten years ago or more, intensity of competition led the trade generally to adopt the installment plan in distributing their goods and, with hardly an exception, manufacturers suffered heavily from the viciousness of the system. The Weed now sell directly to customers or dealers without the intervention of traveling salesmen and expensive branch offices, giving the public the benefit of these economies in reduction of price. Its reputation for fine and durable work, its large plant and efficient corps of native American mechanics, brought to the establishment and to Hartford, in 1878, a new industry which, in magnitude and importance, overshades the production of sewing machines, large as this continues to be. When, in May of that year, Col. A. A. Pope rode circuitously from the station to the office of the company on a bicycle of English make, excited throngs swarmed into the streets through which he passed to catch a view of the strange vehicle. Hundreds of boys took up the line of pursuit, only to find themselves in a few minutes left hopelessly behind. As the Colonel disappeared through the door, the surprise and curiosity were transferred from the outside to the inside of the factory. The object of the visit was not only to place a preliminary order, but to arrange for the manufacture of similar machines on a large scale. The interview, with the business connections growing out of it, have proved eminently satisfactory to both parties. The first lot of fifty bicycles was turned out in season for the fair and races at Framingham. Mass.. Sept. 17, 1878. From that time onward the output, yearly increasing, has amounted to many thousands and the line has been extended to tricycles, "safeties" and "tandems". A very large proportion of the machinery used in the manufacture has been invented by men belonging to the establishment and is made on the premises. Many knotty mechanical problems have temporarily interrupted the onward flow of development, but the ingenuity of officers and men has proved adequate to their solution. From their utility as a means of quick and pleasant travel, these machines and their accessories, little known ten years ago and popularly regarded as a curious but idle toy, have become the staple of a very large trade. Among the different styles on the market, the "Columbias" steadily hold the lead through unequaled excellence of design and workmanship, not less than through the enterprise of the separate company which promotes their use and sale. Struck, while passing through the factory, by the elaborate care taken to adjust the axis of the wheel so that it should coincide exactly with the mathematical center, the writer inquired of president Day in reference to the advantages gained by this extreme, not to say costly, precision. He replied that a slight deviation from accuracy might pass unnoticed for years, but in time would certainly appear and shorten the life of the machine. To the intelligent and scrupulous care bestowed upon the minutest details of construction, the company largely owes its reputation and present prosperity. Wherever tried, at home, on the racing path, or on continental journeys, their work never disappoints the owner.

Since 1880, the Weed Company has often been solicited to enlarge its facilities and make similar machines for other concerns; but having experienced the benefit of close union of effort between maker and seller, based on singleness of interest, it has rejected many offers of contracts and in adhering to a single line, has been assured a continuous and steadily increasing business.

In the winter of 1887-8, the company opened a large and airy reading-room on the sunny side of the building for use during the noon hour. Besides the nucleus of a library, which will be added to from time to time, it is furnished with the leading mechanical papers of the country and with the dailies of the city. Coffee of the best quality is also served to the workmen at cost or a trifle below.

The company employs 250 hands, and pays over $150,000 a year in wages. Its officers are, George H. Day, president and treasurer; F. E. Belden, secretary and John Knous, superintendent. Capital, $240,000.

Published by The Hartford Board of Trade (1889)

SEWING MACHINES STYLES AND PRICES IN 1863

THE MODEL

No. 2 Family $ 50

No. 2 Extra $ 60

No. 2 Half Case & 65 & $ 75

No. 3 & 4 Manufacturing $ 75 & $ 85

1864

506 Broadway, New-YorK

1865

506 Broadway, New-YorK

The new invention, known as the " Weed Lock-stitch Sewing Machine," is rapidly growing in public favor. Since its introduction, no other machine has increased in popularity more steadily. A very wealthy corporation have it in charge and with their numerous and well-established agencies in every quarter, at home and abroad, it would seem that this machine will soon have and deservedly so, a world-wide reputation. Wherever it has been introduced, it has never failed, in a single instance, so far as we know, to give entire satisfaction.

The New York Times, December 16, 1864

?

In 1865 a former Colt’s Armory machinist named George A. Fairfield left the firm to become superintendent of Weed Sewing Machine Company.

In July, 1865, the Company moved to Hartford, Connecticut and reorganized with Jonathan S. Niles as president, George M. Welch as secretary and treasurer. George A. Fairfield later become president of Hartford’s Weed Sewing Machine Company.

1866

From 1866 Weed machines were manufactured for a decade by the Sharps Rifle Manufacturing Company, whose expertise with small arms manufacturing ensured precision engineering. Later Weed took over the factory from Sharps. George A Fairfield, Weed's superintendent had worked for Colt's. Colonel Albert Pope dissolved the company in 1890 to concentrate on bicycle production.

Needlebar.org

1867

George A. Fairfield' Patents

US 63.149 March 26, 1867

US 67.179 July 30, 1867

THE "FAMILY FAVORITE"

It has long been evident to those familiar with the Sewing Machine business, that the real wants of the people had not as yet been met by any of the various machines in the market. To ascertain what might be the deficiencies and then labor faithfully to produce such a machine as would supply the qualities lacking in others, was the first work to which the projectors of the New Weed Company applied themselves and time, labor and capital were freely used for this object. Having satisfied themselves that a more simple mechanism and greater capacity or adaptation to work of all grades were the results to be aimed for in the new machine, a number of the most experienced and competent mechanics in the country were enlisted under the chief supervision of Mr. George A. Fairfield.

The old "Weed" was completely divested of all ancient and cumbersome attachments and appliances, without which it had been heretofore supposed that a Sewing Machine could not properly be made and after much time spent in invention and experiment, the new "F. F." was produced and submitted for approval.

1870

George A. Fairfield' Patent

US 107.019 September 6, 1870

1871

GEORGE A. FAIRFIELD ASSIGNOR TO

THE WEED SEWING MACHINE COMPANY

US 120.731 November 7, 1871

1872

In 1872 the Weed Sewing Machine Company sold about 42.400 machines to reach a total since their start of about 120.000 (160.000) machines.

GEORGE A. FAIRFIELD ASSIGNOR TO

THE WEED SEWING MACHINE COMPANY

US 130.288 August 6,1872

1874

GEORGE A. FAIRFIELD ASSIGNOR TO

THE WEED SEWING MACHINE COMPANY

1874 US 158.167 December 29, 1874

1878

In 1878, with sewing machine sales slumping, George A. Fairfield agreed to a contract in which Weed would manufacture 50 “Columbia” brand bicycles for Colonel Albert Pope.

1881

In 1881 as bicycles boomed, Colonel Albert Pope gained control of Weed Sewing Machine Company and shut it down altogether in 1891, as Columbia produced thousands of bicycles and, later, automobiles.

GEORGE A. FAIRFIELD ASSIGNOR TO

THE WEED SEWING MACHINE COMPANY

1881 US 240.898 May 3, 1881

1885

1890

The Pratt & Whitney Company of Hartford have recently made a large purchase of real estate on Capitol Avenue from the Weed Sewing Machine Company. Part of it they will build upon and part they propose to sell.

Morning Journal and Courier, June 11, 1890

FACTORY FIRE IN HARTFORD

The Weed Sewing Machine Company Works Badly Damaged To-Day

HARTFORD, Sep. 5, 1890. At 10:30 0'clock this morning fire was discovered in the Weed Sewing Machine factory, where Columbia bicycles are manufactured. The flames were in the room where the steel bearings are made and were caused by the explosion of a can of benzine carelessly overturned by a boy. The factory fire department made an unsuccessful attempt to extinguish the flames and finally an alarm was sounded. After an hour's work the fire was under control. The loss is placed at $ 10.000.

Waterbury Evening Democrat, September 05, 1890

GAS EXPLOSION IN HARTFORD

By a gas explosion at the Weed Sewing Machine Company's works, at Hartford, Connecticut, Charles Anderson, Thomas Kennedy and William Barton were badly burned and the building damaged to the extent of $ 250.

Essex County Herald, December 26, 1890

By 1890, the sewing machine market having collapsed, Weed employed 600 men making safety bicycles alone. Nine years earlier Pope had gained control of Weed and in 1891 he merged it with Pope Manufacturing.

POPE MANUFACTURING COMPANY

1878 - 1915

1881-1890 (Pope owned one-third of Weed)

1890-1891 (Weed controlled by Pope)

In 1877 sensing a commercial opportunity, Albert Pope began importing bicycles from England and hatched a plan to produce them domestically.

In 1878 Albert Pope rode the train from Boston to Hartford, then, to the amazement of the city’s onlookers, rode his high-wheeler from the station down Capitol Avenue (ex College Street) to the Weed Sewing Machine Company. Pope approached factory superintendent George Fairfield with a proposal: would Weed agree to build a test run of 50 bicycles under contract? When Fairfield agreed, Pope (via the Weed Sewing Machine Company) became the first domestic manufacturer of bicycles in the United States.

The Pope Manufacturing Company, maker of “Columbia” brand bicycles, thrived under its owner’s shrewd leadership. Sales boomed and Pope eventually gained control of Weed in 1881; sewing machine production continued alongside bicycles for another decade until Pope phased out the sewing machines in 1891 to focus exclusively on bicycles.

By 1895, Pope’s expanded Hartford operations included five factories set on 17 acres, employing 4.000 workers, making him Hartford’s largest employer.

In 1896, Pope sat for an interview with a reporter for Cycling World, a London-based journal. Pope was coy about his business dealings in London, but must have been satisfied to be exporting his bicycles from Hartford after importing them England 20 years prior! Enjoy this interview in which Pope describes his Columbia bicycles, the bicycle “boom,” and his state-of-the-art Hartford factory complex.

In 1914, the main offices of Pope were moved to Westfield, Massachusetts. However.

In 1915, the Pope Manufacturing Company filed for bankruptcy.

In 1916 Pope was reorganized and renamed The Westfield Manufacturing Company.

As reproduction of historical artifacts, this works may contain errors of spelling and/or missing words and/or missing pages, poor pictures, etc.