- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

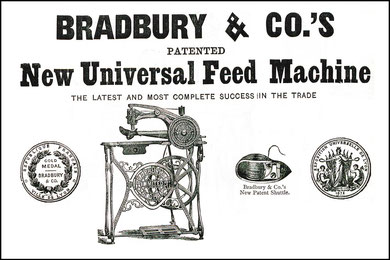

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

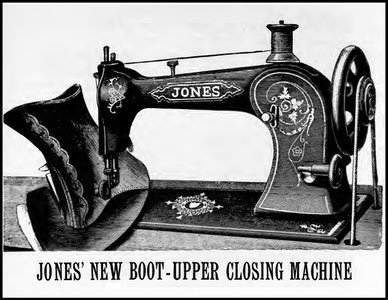

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

SHOE STITCHING MACHINES

FROM 1852

Nichols Bliss

This machine was remodeled so that he was able to use it for stitching shoes. He sold to three Lynn manufacturers, rights to use the machine for stitching leather. Mr. Nichols Bliss asked Mr. Howe for permission to make use of his invention in stitching shoes. Howe replied that Mr. Nichols was the first man who had asked permission to use his invention. Asked why he did not take out a patent for his “invention”, he said: “There was no new principle disclosed in it. It was but an adaptation and rearrangement of known means for accomplishing the purpose”. He did not think it a proper subject for a patent and yet, since that time many hundreds of sewing machine patents have been granted that had but a fraction of the originality that appeared in this design which the modest author thought unworthy of the title of “invention”. There was, however, no occasion for a patent, as his relations with Howe and through Howe with the “Combination”, gave all the protection that any additional patents could have given.

extract from:

LIVING FATHERS OF THE TRADE by Sewing Machine Times

FROM 1858-62

Lyman Reed Blake & Gordon McKay

In 1856 Lyman Reed Blake built an ingenious, yet not entirely practical, sewing machine that could sew the uppers of shoes to the soles. The painstaking and slow process had previously been done by hand. After hearing of the device, Gordon McKay bought the technology with cash and a share of the future profits. Blake received an initial patent in 1858 (US 20.775) that he then sold to McKay; the two men worked together to further improve the device.

In 1862 Gordon McKay and Robert H. Mathies secured a crucial patent (US 36.163) to the improved ready-for-sale version of the sewing machine. Blake, perhaps more of a tinkerer than a grand thinker, would end up working for McKay for the next 12 years, installing the machines.

1862

Auguste Destouy & Charles Goodyear

In 1862 Auguste Destouy, a New York mechanic, invented a machine with a curved needle for sewing turn shoes (US 34.413). This was later improved by as many as eight different mechanical experts employed by Charles Goodyear. The machine was afterwards adapted to the sewing of the welt in the bottom of the shoe, with patents in 1871 and 1875 and became the famous Goodyear welt machine. This marks the third great period of development in shoe machinery. McKay and Goodyear were not themselves originators; they adapted and promoted the inventions of shoe worker and mechanic. Other inventions no doubt lacked such promoters and were lost to the industry.

SHOE MACHINERY by Frederick J. Allen 1916

Definitions of welt

Noun: a leather rim sewn around the edge of a shoe upper to which the sole is attached.

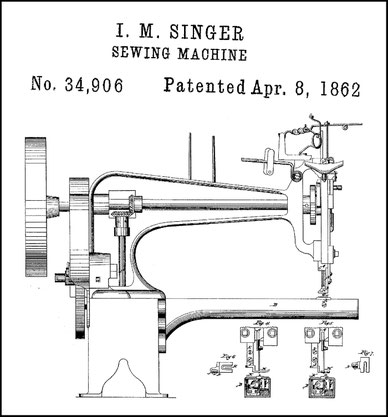

1862

I. M. Singer

1878

Baer & Rempel

1894 c.

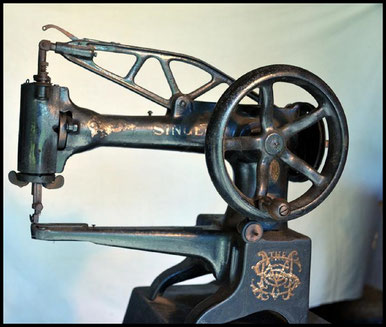

Singer model 29

1900 c.

Singer 29K 2

SHOE CONSTRUCTION TECHNIQUES

Blake Stitch/McKay Method

The machine for Blake construction was invented in 1856 (perhaps it was patent US 20.775 July 6, 1858 ) by Lyman Reed Blake. He later sold the patent to Gordon McKay, hence the alternate name.

Another child of the Industrial Revolution, it’s often referred to as a “Blake Stitch” and is less labor-intensive than Goodyear welting.

This is very common on Italian shoes, which rely on the sleekness that this type of construction provides. The process is relatively simple: Upper is wrapped around the insole and these two parts are stitched to the sole. A single stitch attaches everything. No intermediate layers, no double stitches.

Pros: Less expensive than a Goodyear welted shoe but can still be resoled. Also more flexible and lightweight than Goodyear due to that absence of the welt layer. Also great for shoes that require a close-cut sole that’s flush with the upper because there are no exterior stitches.

Cons: Soles are less waterproof because the stitching allows water to seep in and the thinness of the sole wicks water into the shoe. A rubber sole would eliminate this issue, however.

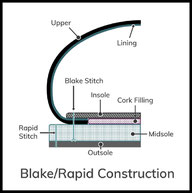

Blake/Rapid Construction

Blake-Rapid construction for shoes is a hybrid of Blake and Goodyear constructions. It adds the mid-layer welt found in Goodyear welt construction but keeps the Blake-stitching technique. This is typically seen on bulkier, more rugged shoes.

Pros: More water-resistant and durable than Blake stitched shoes, less expensive than Goodyear welts

Cons: Less flexible than Blake stitched shoes, not as well-constructed as Goodyear welted shoes.

Goodyear Welt Construction

Goodyear welted shoes are widely considered to be the best constructed around. It’s the oldest and most labor-intensive construction method in existence. It’s constructed in such a way that any cobbler can resole this shoe repeatedly and it’s incredibly durable. Usually made with double soles with outsoles that jut out from the upper, this construction method is widely utilized in British footwear in particular. Like all shoes, these were originally made by hand. Charles Goodyear, Jr. invented the machine to welt these shoes back in 1869. As you probably figured, this is where the name comes from. Though there are multiple steps throughout the whole process, but the main three are as follows:

1. Prepare the insole for stitching. The cordwainer creates a “rib” that runs across the insole. Some makers cut and sculpt the insole, and others use a different material like linen tape. The purpose of the rib is to house thread in a later step.

2. Attach the outsole and insole to the last.

3. Welt: Shoe-specific thread is sewn through the welt, upper, and insole rib. The welt is then attached to the outsole through a second, separate stitch. A lockstitch is used for both of these stitches, which prevents unraveling if it wears out at any point in the shoe.

Pros: The upper is attached to the welt via one stitch, whereas the outsole is attached to the welt via a second separate stitch. Incredibly easy to resole repeatedly as a result, this extends the life of the shoes for years and years. The extra layers help with water resistance and support.

Cons: Some flexibility is lost with all these layers. Also, because the process is labor-intensive, Goodyear welted shoes are often more expensive than other types.