- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

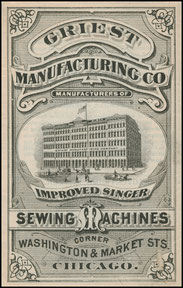

GREIST MANUFACTURING COMPANY

ESTABLISHED 1871

from 1871 to 1892 Chicago, Illinois

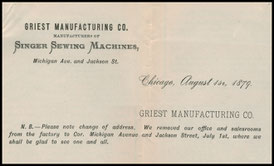

up to 1879 (Corner) Washington & 86 - 88 Market Streets Chicago

In July 1, 1879 removed office and salesrooms from the factory to Cor. Michigan Avenue and Jackson Street

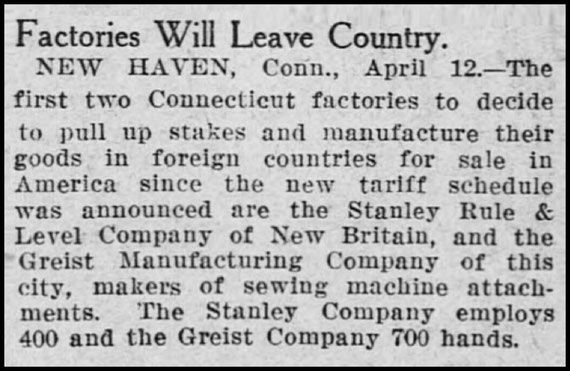

from 1892 to 1970 446 Blake Street, Westville, New Haven, Conn.

in 1961 was merged into the MITE CORPORATION

Greist Manufacturing Company of New Haven, Connecticut, a manufacturer that made sewing machine attachments and Singer sewing machines and equipment for the U.S. Navy during World War II, was profiled in the December 5 issue.

A third generation company, Greist had completed a $3 million, top-to-bottom modernization. (If $1=$1 in 1913, $2.71 in 1955 and $19.37 in 2005, our calculator indicates Greist spent around $50 million in 2005 dollars.) The company was betting that home sewing would boom and women would want more sewing machine attachments to do fancier kinds of work. The company's revitalization involved purchasing new equipment, such as a Minster 22-ton press and implementing the best plant layout for modern "straight-line" production. Topics included quality control spurs modernization, modernizing the pressroom cuts costs, good tool design provides springboard for quality work and lower costs, multi-spindle machines cut costs sharply, and modern tool room backs up Greist production. Home sewing did take off in the post-war era, but times would change and women would leave their sewing rooms to re-enter the workforce.

-----------------------------------------------------------------

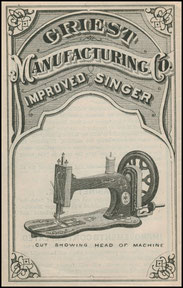

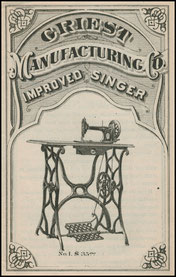

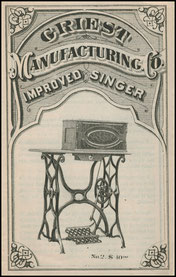

When the sewing machine manufacturers started cloning Singer New Family 12

... This Singer New Family was an amazing machine for it's day and still is a truly spectacular sewing machine! Eventually known as the Singer Model 12 (12K if made in Scotland), it was one of the most copied machines ever. It's design was enlarged to the Model 13 for Tailor use and enlarged to the Model 48K as a High arm machine. This machine and it's smooth Transverse design was copied by virtually every country in Europe that was making sewing machines at the time. ...

... The other members continued the "Combination" until 1877, when the Bachelder patent, which had been extended twice, finally expired. By that time the fundamental features of the sewing machine were no longer controlled by anyone. Open competition by the smaller manufacturers was possible and a slight reduction in price followed. Many new companies came into being, some destined to be very short-lived. From the beginning to the end of the "Combination" there was an army of independents, including infringers and imitators, who kept up a constant complaint against it, maintaining that its existence tended to retard the improvement of the sewing machine and that the public suffered thereby. In the period immediately following the termination of the "Combination", however, only a few improvements of any importance were made and most of these were by the member companies. ...

... Featured in the Sears Roebuck & Co. 1894 catalog were copies of the Singer Models 12 and 48K and a vibrating shuttle model made by the Goodrich Sewing Machine Company of Chicago, Illinois. The two Singer machines were marketed as the 'Improved Singer' and 'Improved High-Arm Singer', in blatant violation of trademark laws. The 'Improved Singer' would appear in later catalogs as the 'Success' probably a result of threatened or actual litigation by the Singer Manufacturing Co. ...

-----------------------------------------------------------------

THE GRIEST

IMPROVED SINGER

1881

From GRIEST To GREIST

There is not a lot of information on the web about this company. It may have started as a bicycle shop. The founder, John Milton Greist (1850-1906) apparently changed the spelling of his name around 1881, because his company was originally called the Griest Manufacturing Company.

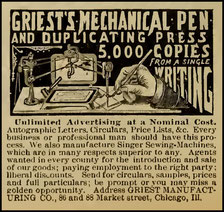

The company had a large facility in Chicago, but also seems to have been located out of New Haven, Connecticut. In addition to sewing machine attachments (for which the founder had around 50 patents, a number of which were sold to Singer, including the famous "puzzle box") the company also made lamps, razors, measuring tools and "Griest's Mechanical Pen and Duplicating Press". In any event, John M. Greist became a very wealthy man, building his stately home "Marvelwood" on a 700-acre nature preserve onto which he brought a herd of elk and deer. He called his home his hobby and the public were allowed to visit. It's now the site of the Yale Golf Course, which may not be as accommodating to public visits. The Greist firm seems to have soldiered on until around the 1960's or 1970's, when the Japanese became ascendant in this market area.

1913

1929

NATION'S SEWING MACHINE FITTINGS PRODUCED HERE

New Haven Evening Register, April 1929

In New Haven is situated the only plant manufacturing sewing machine attachments in the United States. Whenever women here take out their sewing machine and engage in making their own and their families' spring or winter wardrobes, no matter what make machine they use, the rufflers, hemmers, braiders and other accessories are products of the Greist Manufacturing Company. This industry is not one of those founded in New Haven. It was begun originally in Chicago by John Milton Greist in 1871. Mr. Greist was one of the earliest inventors of attachments for sewing machines. Prior to the time when he first begun manufacturing them, sewing machines could do little else than sew straight seams. All the ruffling, tucking, gathering and braiding that was so fashionable on women's garments in the mauve decade had to be sewed by hand. The machine was not then equipped with any labor- and time-saving devices as it is today.

At that time, when a woman bought a sewing machine whatever attachments she wanted, she had to purchase extra. A machine did not come fully equipped. It was not until 1889 that sewing machines companies adopted the policy of selling the attachments with the machines under one price.

In those years there were other manufacturers of sewing machine attachments. Dr. E.J. Toof was putting them out on a small scale in New Haven and there were several other plants scattered throughout the United States.

Mr. Greist moved from Chicago to New Jersey, where he stayed only a short time. In 1890, he came to New Haven and started an assembling plant on Court Street. In 1892, encouraged by E.B. Beecher, match machinery inventor and manufacturer of the Beecher Matches, he purchased the old Clark Bit Factory in Blake Street. At the time of the purchase the building was a three-story structure with only twenty-five thousand square feet on floor space. During the years that followed, the company, which was now incorporated as Greist Manufacturing Company, gradually acquired the attachment business of all sewing machinery manufacturers and had in the meantime bought out the interests of three other competitors, included Toof Company of this city, the Johnston Ruffler Company of Ottomwa, Iowa and Winslow R. Parsons Company of Chicago, Illinois.

As did many other New England plants, the factory manufactured small munitions for the government during the years of the World War and at the time of the Armistice 750 men and women were employed in the Greist plants, including those working in two overflow buildings. Approximately 80 percent of the work turned out then was munitions. Since the war, other lines have been introduced in order to utilize the increased facilities of the concern. These include the production of portable clamping electric lamps for reading and drop wires for weaving, used in the textile industry.

Because of the precision quality of the business, the Greist Manufacturing Company has been able to take orders for the manufacture of a paper cup-making machine. The plans now cover 125.000 feet of the floor space and there are four separated buildings. Sewing machine attachments are made for the White, Singer, New Home, Free, National, Willcox & Gibbs and Standard sewing machine companies and, because each machine requires attachments in proportion to fit each standard type, much of the work is of the highly specialized type. The work itself does not call for specially designed machinery but the tools and dies are all made in the tool department maintained by the company and the most able die makers are required.

At the present time three hundred men and women are employed and practically all of the work is skilled. Mrs. Greist is president of the concern and W.C. Greist vice-president and treasurer.

Westville: Tales from a Connecticut Hamlet

By Colin M. Caplan

HUBERT GREIST, LED MACHINE COMPANY

Branford, Connecticut, August 18, 1970

Hubert M. Greist Jr., former president of the Greist Manufacturing Division of the Mite Corporation, died here yesterday. He was 59 years old and lived at 21 Island View Avenue. He was with the family company from 1934 until his retirement in 1968.

The business, which manufacturers sewing machine attachments, was founded by his grandfather, John Milton Griest, in Illinois in 1871. It moved to its present location on Blake Street, New Haven, 22 years later. It was merged into the Mite Corporation in 1961.

Mr. Greist was a 1934 graduate of Yale University's Sheffield Scientific School. He served in the Navy during World War II as a lieutenant comander. He had been president of the Pine Orchard Yacht and Country Club.

He is survived by his widow, Mrs. June Mendillo Griest; son, Hubert M. 3d; a daughter, June and three sisters.

August 19, 1970 Page 39

New York Times

***

John M. Greist, the past president, treasurer and general manager of the Greist Manufacturing Company, which made sewing machine attachments, built his home at “Marvelwood” with a 700-acre backyard, now the site of the Yale Golf Course. Mr. Greist brought a herd of elk and deer to his land to create a game reserve. A wire fence surrounded the preserve, seven miles long. If straightened, the fence would stretch from Woodbridge to the New Haven Green. Of his beautiful home and magnificent grounds, Greist said, “Marvelwood is my hobby.” The public was allowed to visit. The fence had seven gates on Forest Road, Curriculum Unit 79.03.01 8 of 13 Fountain Street and at other points.

***

-----------------------------------------------------------------

Anson Beecher and Ebenezer B. Beecher, of New Haven, New Haven county, in the State of Connecticut, have invented a new and useful Machine for Framing Lucifer-Match Splints for Dipping.

February 3, 1863

-----------------------------------------------------------------

Ebenezer B. Beecher and Lucius Wheeler Beecher, of the city and county of New Haven and State of Connecticut, have invented certain new and useful improvements in the manufacture of Wooden Boxes for Matches.

February 23, 1869

-----------------------------------------------------------------

Ebenezer B. Beecher, of Westville, New Haven county, Connecticut and William H. Swift, of Wilmington, county of New Castle, State of Delaware, have invented an improved Paper-Box.

March 5, 1872

-----------------------------------------------------------------

***

Two early twentieth-century factory complexes stand on Blake Street. Since the late eighteenth century, the parcel at 495 Blake Street has continuously been the site of various mills and factories. The Geometric Tool Company purchased the land and buildings left behind by the Diamond Match Company in the early twentieth century and erected the structures that now stand there. The main building is a two-story Colonial Revival influenced masonry industrial structure. The facade of the main block incorporates a denticulated stringcourse and segmental window headers. The west side of the complex has a long, two-story brick-masonry wing (Inventory #2; Photographs #11).

The Greist Manufacturing Company formerly occupied the industrial complex across the street from the former Geometric Tool Company, at 446 Blake Street. This complex of early twentieth-century industrial structures was built between 1906 and 1948. The Colonial Revival main industrial building is a 2-story, brick structure with a flat roof, segmental and semicircular window headers and door openings and a projecting cornice with modillions (Inventory #1; Photograph #12). Other later twentieth-century wings have been added to the east elevations.

The Greist brothers briefly owned a bicycle shop in downtown New Haven before forming the Greist Manufacturing Company in 1894, with Ebenezer Beecher as the company's first president. The company set up shop across the street from Geometric Tool and manufactured sewing machine attachments and "other mechanical specialties". Early in the twentieth century, the company built a complex of industrial structures that are still standing and now are occupied by the New Haven Manufacturing Company.

***

Beecher and Sons, manufactures of matches and fruit baskets, was built on the site of the Bunce papermill. The company became the largest producer of sulfur matches in the country between 1856 and 1866, and invented the first machine for dipping matches.

Beecher and Sons went through several mergers with its competitors, finally emerging as the Swift, Courtney and Beecher Company. In 1880, the company incorporated under the name of the Diamond Match Company and moved operations in Chicago, leaving behind an empty factory complex. The Geometric Tool Company began leasing the facilities left by Diamond Match in the early 1890s. That company later purchased the site and erected new structures in the early 20th century. The Geometric Tool Company produced the Automatic Self-Opening Die Head, a patented device that aided in the mass production of threaded metal parts. The company remained in operation on the site for nearly one hundred years. The buildings underwent adaptive reuse in the 1980s and the complex is now known as the Blake Street Center.

The Greist brothers briefly owned a bicycle shop in downtown New Haven before forming the Greist Manufacturing Company in 1894, with Ebenezer Beecher as the company’s first president. The company set up shop across the street from Geometric Tool and manufactured sewing machine attachments and “other mechanical specialties.” Early in the 20th century, the company built a complex of industrial structures that are still standing, and mid-century additions have been replaced by modern apartments.

The expansion of the Geometrical Tool and Greist Manufacturing companies prompted the laying out of Tour and West Rock Avenues. Garrett Fitzgerald, who subdivided the property, acquired the land within the horseshoe-shaped side street early in the century. Tour Avenue was for a brief time named “Greist Avenue,” presumably because the road led to the factory. West Rock Avenue was named Tryon Avenue until the late 1930s. It was actually an extension of the portion of Tryon Avenue that lay on the other side of Whalley Avenue. The houses built on this side street were multiple-family dwellings that housed employees who worked at the nearby Greist and Geometric Tool companies or in businesses on Whalley Avenue. Fitzgerald also owned the parcels along Whalley Avenue between Tour and West Rock. The houses built there were initially single-family residences.

Commercial development continued along Whalley Avenue until well into the 1920s, and later, as the nation emerged from the Depression of the 1930s, the Greist Manufacturing and Geometric Tool companies contributed to reviving the city’s industrial life.