GB PATENTS

FOR

GLOVE-SEWING MACHINES

In February, 1822, Mr. James Winter, of Stoke-under-Hambdon, in the county of Somerset, obtained a patent for an improvement upon a former patent machine of his for sewing and pointing leather gloves.

A Dictionary of Arts, Manufactures and Mines (London 1843)

the only patents that I could find in the name of James Winter are shown below but with different dates and a patent for scaffolding

GLOVE MANUFACTURE

In February, 1822, Mr. James Winter, of Stoke-under-Hambdon, in the county of Somerset, obtained a patent for an improvement upon a former patent machine of his for sewing and pointing leather gloves.

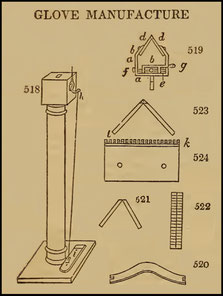

Fig. 518 represents a pedestal, upon which the instrument called the jaws is to be placed. Fig. 519 shows the jaws, which instead of opening and closing by a circular movement upon a joint as described in the former specification, are now made to open and shut by a parallel horizontal movement, effected by a slide and screw; “a a” is the fixed jaw, made of one piece, on the under side of which is a tenon, to be inserted into the top of the pedestal. By means of this tenon the jaws may be readily removed and another similar pair of jaws placed in their stead, which affords the advantage of expediting the operation by enabling one person, to prepare the work whilst another is sewing; “b b” is the moveable jaw, made of one piece. The two jaws being placed together in the manner shown at Fig. 519, the moveable jaw traverses backwards and forwards upon two guide-bars, c, which are made to pass through holes exactly fitted to them, in the lower parts of the jaws. At the upper parts of the jaws are what are called the indexes, “d d”, which are pressed tightly together by a spring, shown at Fig. 520 and intended to be introduced between the perpendicular ribs of the jaws at e. At f is a thumbscrew, passing through the ribs for the purpose of tightening the jaws and holding the leather fast between the indexes while being sewn; this screw, however, will seldom, if ever, be necessary if the spring is sufficiently strong; g is an eye or ring fixed to the moveable jaw, through which the end of a lever, h, in Fig. 518 passes; this lever is connected by a spring to a treadle, t, at the base of the pedestal and by the pressure of the right foot upon this treadle, the moveable jaw is withdrawn; so that the person employed in sewing may shift the leather and place another part of the glove between the jaws. The pieces called indexes are connected to the upper part of the jaws, by screws passing through elongated holes which render them capable of adjustment. The patentee states, that in addition to the index described in his former patent, which is applicable to what is called round-seam sewing only and which permits the leather to expand but in one direction when the needle is passed through it, namely, upwards, he now makes two indexes of different construction, one of which he calls the receding index and the other the longitudinally grooved index. Fig. 521 represents an end view and Fig. 522 a top view of the receding index, which is particularly adapted for what are called “drawn sewing and prick-seam sewing”; this index, instead of biting to the top, is so rounded off in the inside from the bottom of the cross grooves, as to permit the needles, by being passed backwards and forwards, to carry the silk thread on each side of the leather without passing over it. Fig. 523 represents an end view of the longitudinally grooved index, partly open, to show the section of the grooves more distinctly and Fig. 524 represents an inside view of one side of the same index, in which the longitudinal groove is shown passing from k to l. This index is more particularly adapted to round seam sewing and permits the leather to expand in every direction when the needle is passed through it, by which the leather is less strained and the sewing consequently rendered much stronger.

It is obvious that the parallel horizontal movement may be effected by other mechanical means besides those adopted here and the chief novelty claimed with respect to that movement, is its application to the purpose of carrying the index used in sewing and pointing leather gloves.

Importation of leather gloves for home consumption; and amount of duty in:

1836 1837 1836 1837

1.461.769 1.221.350 £27.558. £22.923

GLOVE-SEWING

The following simple and ingenious apparatus, invented by an Englishman,

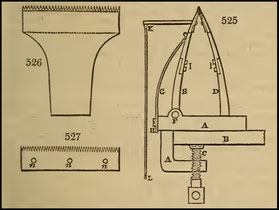

has been employed extensively in Paris, and has enabled its proprietors to realize a handsome fortune. The French complain that "it has inundated the world with gloves, male of excellent quality, at 30 per cent. under their former wholesale prices". The instrument is shown in profile ready for action in Fig. 525. It resembles an iron vice, having the upper portion of each jaw made of brass and tipped with a kind of comb of the same metal. The teeth of this comb, only one twelfth of an inch long, are perfectly regular and equal. Change combs are provided for different styles of work. The vice a a is made fast to the edge of the bench or table b, of the proper height, by a thumb-screw c, armed with a cramp which lays hold of the wood. Of the two jaws composing the machine, the one D is made fast to the foot A A, but the other e is moveable upon the solid base of the machine, by means of a hinge at the point F. At I I is shown how the upper brass portion is adjusted to the lower part made of iron; the two being secured to each other by two stout screws. The comb, seen separately in Fig. 527, is made fast to the upper end of each jaw, by the three screws nnn. Fig. 526 is a front view of the jaw mounted with its comb, to illustrate its construction. The lever k corresponds by the stout iron wire l, with a pedal pressed by the needlewoman's foot, whenever she wishes to separate the two jaws, in order to insert between them the parallel edges of leather to be sewed. The instant she lifts her foot, the two jaws join by the force of the spring g, which pushes the moveable jaw e against the stationary one D. The spring is made fast to the frame of the vice by the screw H. After putting the double edge to be sewed in its place, the woman passes her needle successively through all the teeth of the comb and is sure of making a regular seam in every direction, provided she is careful to make the needle graze along the bottom of the notches. As soon as this piece is sewed, she presses down the pedal with her toes, whereby the jaws start asunder, allowing her to introduce a new seam and so in quick succession. The comb may have any desired shape, straight or curved and the teeth may be larger or smaller, according to the kind of work to be done. With this view, the combs might be changed as occasion requires; but it is more economical to have sets of vices ready mounted with combs of every requisite size and form.

-----------------------------------------------------------------

GB 3.012 James Winter

Machine for sewing, &c. leather Gloves

A grant unto James Winter, of Stoke-under-Hamdon, in the county of Somerset, glove manufacturer, for his invented machine for sewing and pointing leather gloves with neatness and strength, much superior to that which is effected by manual labour; to hold to him, his exors/admors and assigns, within that part of our united kingdom of Great Britain and Ireland called England, our dominion of Wales and town of Berwick-upon-Tweed for the term of fourteen years pursuant to the statute; with a clause to inroll the same within one calendar month from the date thereof. By writ, &c.

February 20, 1807

-----------------------------------------------------------------

GB 4.627 James Winter

Machine for sewing, &c. leather Gloves

A grant unto James Winter, of Stoke-under-Hamdon, in the county of Somerset, gentleman, for his invtd " Certain improvements in a machine for sewing and pointing leather gloves with neatness much superior to that which is effected by manual labour "; 2 months. By writ, &c.

December 19, 1821

-----------------------------------------------------------------

GB 10.412 J. Winter sen. & jun. & W. Lane

Scaffold, or mode of scaffolding

James Winter, senior, of Wardour Street, Soho, Upholsterer, James Winter, junior, of the same place, Upholsterer and William Lane, of Bedford Place, Russell Square, Middlesex, Gentleman, for an improved scaffold or mode of scaffolding, applicable also as a fire-escape for life and property. Sealed (Six months.)

December 2, 1844

-----------------------------------------------------------------

GB 1.414 Abel Foulkes

of the City of Chester, Glove Manufacturer, for improvements in sewing or pointing gloves and in machinery for such purposes. Letters Patent sealed.

May 20, 1857

-----------------------------------------------------------------

GB 187 Richard Archibald Brooman

Glove-Sewing Machine

of 166, Fleet Street, in the city of London, Patent Agent, for the invention of “Improvements in sewing machines, particularly applicable to the stiching or sewing of gloves and other articles where circular or partially circular parts are to be connected together”. A communication to him from abroad by Edouard Paul Lecerf, of Paris. On their several petitions, all recorded in the Office of the Commissioners

January 23, 1861

-----------------------------------------------------------------

Norway Patent

N 40 F. S. Perrare-Michael, of Paris, for “Sewing machines for gloves, &c.”–10 years. May 10, 1878

-----------------------------------------------------------------

GB 1.556 Carl Necker & Richard Horstmann

Glove-Sewing Machine

both of Berlin, Prussia, Germany, have given the like notice in respect of the invention of “an improved sewing machine, chiefly designed for quilting kid and other gloves". As set forth in their respective petitions, both recorded in the said office.

April 19, 1879

-----------------------------------------------------------------

-----------------------------------------------------------------

Fiddlebase

Fiddlebase