- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

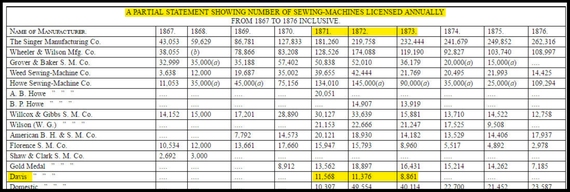

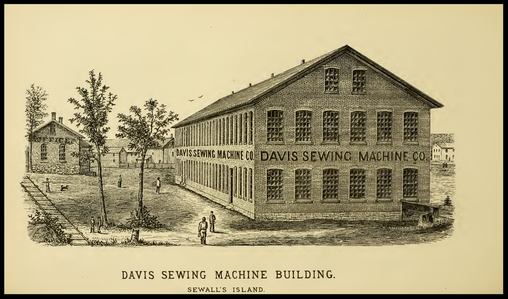

THE DAVIS SEWING MACHINE CO.

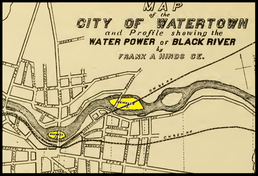

Watertown, N.Y. 1868-1889

Dayton, Ohio 1889-1924

In 1866 Job Anthony Davis went to Watertown where he displayed his new sewing machine at the Woodruff house. The Woodruff House was a large hotel that stood on Public Square , built after the Great Fire of 1849.

After careful examination, Mr. John Sheldon was induced to organize a company that would make the needed investment to secure a plant for its manufacture. It so happened that the Hon. Joseph Sheldon, brother of John, was an intimate friend, at New Haven, Conn., of that Elias Howe, who invented the first machine and was then largely interested in the manufacture of sewing machines. He examined, at Mr. Joseph Sheldon’s request, the Davis machine, before any investment had been made for its manufacture at Watertown and pronounced the device novel and valuable. This was the opinion upon which Mr. John Sheldon and the company organized by him, based their willingness to put money into manufacturing the Davis machine.

In February 1868 The Davis Company was organized at Watertown Jefferson County, N.Y., with a cash capital of $ 150.000, which capital stock was subsequently increased to $ 300.000. The company was principally financed by well-known citizens of that town.

The first plant operation, starting with 10 employees, was located in the old stone building on Beebee Island. The machines made were at first very few in number

Here was trouble. The “combination” so called, composed of the Singer, Wheeler & Wilson and Grove & Baker companies, who shared royalties in common on certain patents, claimed that the Davis was an infringement.

By January 1869 the Davis Sewing Machine Company have settled the action brought against them for the infringement of a patent paying to them 40 cents on early Davis machine manufactured.

Although the Company thought they were not legally liable, they thought it wiser to buy the right to use the patent than to engage in an interminable litigation and have their customers kept in fear of prosecution. With this obstacle now removed, the Davis Sewing Machine Company, of which G. W. Goodrich was the financial manager, was destined to be the largest and most prosperous manufacturing enterprise ever established in Watertown.

Here was trouble again. The 40 cents royalty, paid by the Davis Company, was less than other companies paid and was thus a violation of contract with them. The Florence heard of it and refused longer to pay more than the Davis was paying. So representatives of the combination went to Watertown and tried to buy up the Davis. In this they failed, but succeeded in making a contract with the company whereby they were to build for them 30.000 machines at a fixed price per machine in about three years and as many more as might be wanted. They sent on men and the work commenced.

At that time the Company was employing 60 men and will have soon a regular force of 100 workmen. They turn out about fifteen complete machines per day and in the spring the number was increased to twenty five. But the best business indication is that they have constantly on hand a large number of orders more than they could fill. They have depended solely on the merit of their machine to sell it and wherever it has been tried it gives unqualified satisfaction. As an example of its success, was that their agent in Canandalgua, an old village where every established sewing machine had an agency, sold twenty-two of the Davis machines to dress makers and other expert sewers. This is a practical test of its superior quality. The vertical feed, which is peculiar to this machine, is of great advantage, especially in the sewing of fine fabrics. The Company was making a new machine for sewing leather and the thickest kinds of cloth, which bids fair to take the lead in this class of machines.

On a Friday 23 April, 1869, a flood on the Black River, with unabated violence are swept away most of the factories in Watertown. The Davis Sewing Machine Company's furnace and machine shop was swept out, leaving that branch of the river a scene of ruin.

An April 24, 1869 news article stated "The Davis Sewing Machine Company is manufacturing a new and greatly improved machine for heavy work, which seems to be taking precedence over all others. The company recently received an order for 1.400 machines from a firm in Paris, France and will deliver them during the ensuing three months. All employees of the company are working full time and orders are being received which test the full capacity of the factory.

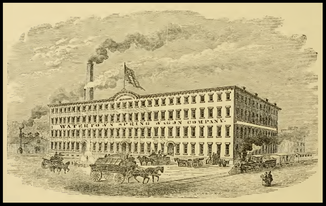

The Company's Works were very extensive; equipped with the latest and most approved machinery and worked by the best mechanical skill the country afforded. The demand for their machines was unprecedented and to provide for the rapidly increasing sales it was found necessary to invest an extra $ 100.000 in tools, machinery and stock.

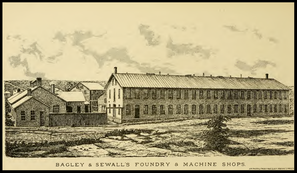

Due to the flood and the order they received from Paris, arrangements were made with Bagley & Sewall to do the casting of the iron parts and with the firm Lewis, Henrich & Rounds, situated near Factory Street, to do the wood work. In 1876 Henrich & Rounds were still manufacturing much of the wood work for the Davis S. M. Co..

Trouble, trouble, trouble. The consequence to have a contract with the “combination” was that the machines were miserably constructed, their reputation began to suffer and it became pretty evident that one object of the contract was to ruin in the market the new and formidable competitor of the “combination” machines. If this was the intention it was partially successful, as imperfect machines were returned in large numbers and sales fell off.

In 1870 the Winslow Industrial Building on Factory Square, erected by Hon. N. Winslow, was occupied by the Davis Sewing Company. The building was 283 X 55 feet, four stories high and built of bricks. In 1876 the building was occupied by the Watertown Spring Wagon Company.

In 1871 Mr. Levi A. Johnson was induced to give up his partnership in the Great Wardrobe clothing store (Wiggins & Johnson), and accept the office of secretary and treasurer with the Davis Sewing Machine Company . The Davis Company paid royalty to the “ combination “.

At last, in 1872, the “combination” stepped out of the shops and the company stepped in and the work of reform in manufacture and recovery of good name commenced in earnest.

In 1874, royalty were paid not more.

In 1875 the company erected a building of its own in Sewall’s Island near the finest water power on the river. The main building was two stories with attic and is 175 X 40 feet. The wing was the same high and was 40 X 30 feet. The office was one story, 50 X 30 feet, all the building being of bricks. The company manufactured $ 300.000 worth of machines, all of which found ready sale. The number of employees was 175. The works were driven by water power, over 50 horse being used. The assets of the company were about $ 1.000.000.

The company was so well established in the city that it sponsored a city band which under the name of "Davis Sewing Machine Band" won band competition prizes in Canada. The citizens of Watertown provide each season for open air concerts in the park on Public Square, during the summer season on Saturday evenings by the Davis Sewing Machine Band, one of the finest in the country. The concerts are listened to by admiring audiences numbered by thousands, and form an interesting feature of mid-summer social life.

100.000 Sewing Machines December 1877

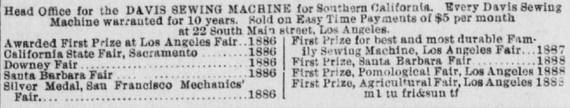

April 11, 1881 Melbourne International Exhibition

J. Cosmo Newberry, Esq., Superintendent of Juries and Awards

Sir, according to your instructions we have made a practical and thorough examination of the following sewing machines, viz :

The Bradbury, Wertheim, Grimme Natalis, Wheeler and Wilson, Jones and Co., Johnson, Clark and Co., and the New Davis, and the results of our test and experiments are set forth in the tabulated statements attached. We find that the Bradbury, Wertheim, Grimme Natalis, and Jones are all of the Singer type and should be classed in the same order. The Wheeler and Wilson differ in construction, but the results of our experiments are similar to the others.

The standard of Messrs. Johnson, Clark and Co., is the only machine submitted, except the Davis, having a radial shuttle movement, and therefore worthy of the consideration of the judges.

As regards the New Davis we cannot but agree with the judges that it is very superior to any of the others and went through every test to our entire satisfaction. We therefore beg to recommend that machines be placed in the following order :

Family Machines

1st. The Davis (awarded First and Special and the Gold Medal.)

2nd. The Standard.

3rd. Grimme Natalis , Jones and Co., Bradbury, Wheeler and Wilson, Wertheim, Cramer

Hand Machines

1st. The Davis, (awarded First and Special.)

2nd. The Standard, Wertheim.

3rd. Bradbury, Jones, Cramer, Wheeler and Wilson.

Signed, Bobart, Quarry, Experts.

If any additional testimony of the excellent qualities of the " Davis " machine were needed, we should have great pleasure in adding that after careful examination and testing we find this machine is splendidly made, is constructed of the best materials, is excellently finished, and will stitch all classes of work heavy or light so beautifully as to be almost astonishing.

In 1882 the Davis company, having ramifications in most towns in the United States of America, opened offices at 54, Queen Victoria St., London determined on pushing an English trade. The Davis company will be known as the Vertical Feed Company.

In 1884 the Davis Sewing Machine Company in America have placed on the market a new device for connecting sewing machines with motive power. It is a friction clutch and brake, invented by Mr. C. H. Rohde, of the Company’s Chicago office. This clutch may be used with any of the leading sewing machines in the market and is well worth the attention of all who use machines driven by power. It is said to be very simple in principle and construction and in its application and operation it is free from complication. Being simple, it is easily applied and understood and is not liable to get out of order. It is fastened to the table or bench and is controlled by a treadle, fastened to the floor and connected with it by a rod. The friction is quickly applied and released and the section is instantaneous, positive and direct, either in starting or stopping the machine. On the clutch are two belt grooves on the delivery shaft or pulley, by which a variation of speed of about thirty-three per cent may be obtain.

Job Anthony Davis died on Sunday January 31, 1886 at Wollaston, Mass.

Unfortunately, in the late 1880's, as newspaper accounts in the Watertown Daily Times relate, an unwise policy of permitting poor work to go out of the factory and under the depression induced by this policy, the concern ran deeply in debt. Workers were laid off and the operation in the late 1880’s was curtailed to part-time employment. The financial picture was further complicated by an expensive law suit, according to The Times reports, so that finally the company defaulted.

The case of the Hat Sweat Manufacturing Company of New York, against the Davis Sewing Machine Company of Watertown, which has been in the United States Court for two years, was decided by Judge Wallace on October 12, 1889. The case was brought for infringement of a patent owned by the Hat Sweat Company for stitching the leather or other sweat band to the hat in such a manner as to conceal the edge of the lining. Hon. Roscoe Cookling two years ago argued the motion for an injunction against the Davis Sewing Machine Company, who were turning out precisely the same kind of work as that which the Hat Sweat Company claimed to have covered by its patent. The mechanism made by the Davis company was also patented and they realized the claim for infringement on the ground of priority, holding that if there was an infringement, the Hat Sweat Company were the infringers and not the Davis Company. Judge Wallace in his decision filed with Clerk Doolittle, dismissed the case, holding there is no invention covered by the Hat Sweat Company's patent, which has been infringed. This will be good to many manufacturers throughout the country, who are now paying a royalty on the hands the Sweat Company, as Judge Wallace's decision does away with their demands.

On December 14, 1888, Mr. Levi A. Johnson secretary treasurer of the Davis Sewing Machine company, sent the following letter to the Dayton board of trade:

Gentlemen, yesterday I had a meeting of my board of directors and they authorized me to say that if the city of Dayton would give us $ 50.000 we will remove our manufactory and business to that city. Answer to be returned by January 3. They decline to hold the matter open beyond that date, hoping you will have no difficulty in obtaining the amount.

According to Dayton reports, the city was thoroughly canvassed but on the 2nd of January 1889 there still remained $ 20.000 to be subscribed. The full amount was raised by the next day and George Huffman was the main contributor. Mr. Johnson in Watertown accepted and prepared the plant, equipment and 50 families for the move to Dayton which occurred in the spring of 1889.

In 1889 The Davis Sewing Machine Co. held their annual shareholders' meeting on the 9th and 10th of January .

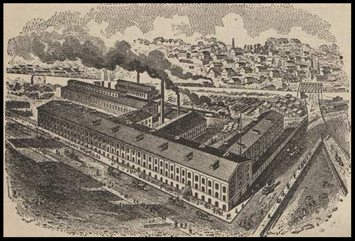

The most important business they transacted was to decide to remove their works from Watertown, New York, to Dayton, Ohio. Their present premises are considered too small, and their removal, Mr. Levi A. Johnson, the secretary, proved would mean a saving of £ 10,000 a year. After due discussion it was resolved that the capital of the company be increased from £ 60,000 to £ 120,000, divided into £20 shares. The new premises will be much larger than the old, and in length some 500 ft. (says the Sewing Machine Advance) by 40 ft. wide. The foundry buildings will be separated from the main building, and there will be several smaller buildings. An engine of 150 h.-p. will be used and all the latest appliances adopted, which will make their factory one of the best equipped in America. The new premises are expected to be ready by the middle of the summer. The Advance says that when all is completed their assets will be close upon £200,000, against which the only liability is £ 120,000 of shares.

A reorganization was made and the company accepted the move to Dayton, Ohio, for $ 50.000 on February 3, 1889.

The Davis Sewing Machine Company, was represented in France, 48, Boulevard Sebastopol, Paris, by Mr. Victor Andre that used to be the sole importer of the old Howe machines.

Mr. L. A. Johnson, superintendent and secretary of The Davis Sewing Machine Company.

Dr. H. M. Stevens, of Watertown, N.Y., president of The Davis Sewing Machine Company.

The Vertical Feed was represented by Mr. George W. Phillips, at 24 Aldersgate Street, London.

Since 1889, after the factory was moved to Dayton, Ohio, the Davis company also began producing models that employ feed dogs. Production continued to 1924.

In 1892, the owner of the Davis Sewing Machine Co. in Dayton, George P. Huffman, recognized the growing trend and began making bicycles. He transitioned his company from sewing machines to bicycles as the Huffman Manufacturing Company, the maker of Huffy bicycles, according to the Huffy website. The Davis Company built there first bicycles for other companies and hardware stores.

1895 was the first year that they produced bikes under their name, "Dayton", the bicycle craze had reached its height in the United States, so the machinery of the Davis plant was partially converted to the manufacture of bicycles. Within a short time, so popular had this model become, the company was called upon to supply the wheels to a number of the country’s largest mail-order houses, and at one time, when production was a its height, more than 20 different name plates were used on the wheels turned out by this plant. All, however, were the same models, merely marketed under the name plate selected by each wholesaler or jobber, or mail order concern, to the trade.

The Davis Sewing Machine Company, who only started a cycle department the present season, report that their sales have exceeded their most sanguine expectations. Whether or not they will attempt to do a trade in cycles in this country we cannot at present say, but thus far they have sold all they could make at home, which would seem to imply that they will not for the present trouble about the English market. The cycle department, we might explain, does not in any way reduce the output of the " Vertical Feed " sewing machines.

By 1897 Davis was the largest manufacturer of bikes in the United States. Davis produced top notch bikes with very fine finishes. All the bikes were produced in the same color, a carmine red.

In 1900, the Burdick was the first Davis sewing machine sold through Sears . This was soon followed by a number of different Minnesota models in the following years. The Minnesota “A” was the best of the models, featuring ball bearing movements and a positive feed mechanism. The models “B” and “C” were lower costing models which did not posses the “A” machine’s various improvements but which nonetheless were a superb deal for the prices they were offered for. During this period, the majority of machines being manufactured by Davis were for sale through Sears.

By 1905 the Davis was producing 600 sewing machines and 600 bicycles every working day, and giving employment to more than 2.000 men and women six days a

week. This steady and substantial payroll served for years to add much to the prosperity of the city generally, and stood the community in good stead at a time when the car works were

disintegrating and there was a constant dwindling of labor forces there. The factory of the Davis (Vertical Feed) Sewing Machine Company, in Dayton, Ohio, is to be again enlarged, thirty-five

houses adjoining the factory having been purchased to permit of the extension.

In 1910, all sewing machines featured in the Sears catalog were manufactured by Davis. But around 1912, Sears again began to contract with other manufacturers for sewing machines. The Franklin, a copy of the Singer Model 27 manufactured by Domestic, as well as a Domestic made Minnesota Model A, were introduced that year. Slowly, the dominance that Davis had held in the Sears sewing machine product line began to decline.

Then along about 1914 the automobile sprang into widespread popularity, and the bicycle was forced to give ground. Following closely on the heels of this new vehicle’s appearance came the World War, and while no one in Dayton realized it at the time, it really sounded the death knell of this famous old industrial plant.

At the command of the government, the Davis halted its production of bicycles and sewing machines and converted a large part of its machinery into the manufacture of munitions. Again the payroll boomed, but it was not the solid, substantial prosperity that had attended its peace-time years. Munitions were provided to meet the government’s demands. But each day that the machinery was on that work it was growing farther away from the time when it could again be utilized for producing the things for which it was originally intended. The regular business of the company suffered. The electric sewing machine came in and was marketed by several competitors at a time when, through force of circumstances, the Davis was unable to meet and cope with such competition. The cry was for munitions and more munitions. The world was being made safe for democracy, but at the cost of the Davis reputation and markets.

In 1916 Davis purchased the Yale and Snell lines from the Consolidated Manufacturing Company of Toledo, Ohio. Davis also purchased the "National" line of bikes from the National Bicycle Company of Bay City, Michigan. Davis kept the National head badge changing only the name of the city in which the bikes were built. Davis even kept painting the bikes the National blue color.

Davis also produced bikes under the names of Duro, Dixie Flyer, LaFrance, Daytonia, Shrayer, Ohio, Shapleish Hardware, Western Auto and Western Flyer.

During the year 1917, roughly one-third of all Harley-Davidson motorcycles produced are sold to the U.S. military. The Quartermasters School, a department of Harley-Davidson devoted to training military mechanics on Harley-Davidson motorcycles, opens for business in July. It will later become the Service School. The sale of Harley-Davidson bicycles begins. Individual components are made by the Davis Sewing Machine Co. of Dayton, Ohio. The bicycles are sold through the H-D dealer network.

By 1919, the last year that Sears carried a Davis model, the only Davis sewing machine featured in the catalog was a Minnesota Model C. Because the company had grown to become so dependent on sales through Sears Roebuck & Co. for its sewing machines, when Davis lost its contract with the company in 1919, it was unable to make up the loss in sales and eventually went out of business in 1924.

Horace Huffman had worked in the business since 1900 and by 1922 he was in charge of liquidating the assets of The Davis Sewing Machine Company. He used the profits from the liquidation to form the Huffman Manufacturing Company. The Davis Sewing Machine Company had survived 30 years in the bike industry, but were finished by 1922.

In 1924 Horace Huffman was put in charge of liquidating the companies machinery . At this time, the company employed 1.800 workers. Huffman used the funds to create the Huffman Manufacturing Company.

The Davis Company was purchased by the National Sewing Machine Company. The remaining Davis bike inventory was sold through 1925.

EXTRA ARTICLES

continuous rotating shuttle

This invention consists, first, of mechanism for operating the feed; second, of mechanism for operating the needle-bar, the feed-bar, and the presser-foot; third, of mechanism for driving a

continuous rotary shuttle, whereby it is made to move at a speed greater at one part of its travel than at the remaining part; fourth, of a continuous rotary shuttle having an elongated eye;

fifth, of a device for deflecting the needle-thread from the path of the shuttle; sixth, of mechanism for confining and releasing a continuous rotating shuttle in a direction at right angles to

its path of rotation; seventh, of an upper and lower feed-bar, arranged, the lower feed-bar to work in one direction from and with the upper feed bar and in the other direction independently of

such upper feed-bar and by mechanism of its own; eighth, of a rotary shuttle-carrier constructed to place and keep the needle in its proper line of movement and, ninth, of a construction of the

raceway for a rotary shuttle-carrier and its shuttle, all substantially as hereinafter described.

*********************************************************

Gold Medal for Davis Sewing Machine Company at The London International and Universal Exhibition 1884

Crystal Palace 23 April, 1884

The London letters to the News during the summer months contained eulogistic accounts of the exhibit of the Davis Sewing Machine Company at the International Exhibition which was being held in London. If we are not mistaken, it was the first occasion upon which the machine, which is popularly known in Europe as the " Vertical Feed ' sewing machine, was publicly exhibited in a competition for honors. The machine's novel and marvelous range of work, both practical and fancy, surprised and delighted the Londoners, to whom it was something new in sewing mechanism, and the booth where the experts were tossing off sample after sample of great variety and singular beauty was one of the most constant crowded points in the exhibition. The jury were so impressed with the capacity of the machine and the novelty of its leading features, that they gave the exhibits a strong recommendation to Superior Council, in whose hands the granting of the awards lay, and the Council, acting upon that recommendation, unanimously voted a gold medal to the Vertical Feed Sewing Machine Company, as the Davis Company is styled in England. The gentlemen at Watertown are to be congratulated, and their representatives in London also, who so creditably and successfully exhibited their machine ; and it is to be hoped that this well merited success will be followed up by an increased and lasting European trade.

The information as to the high esteem in which the Vertical Feed Machine is held in this country is of course strictly correct, but as a matter of fact, and fact only, there is an obvious error as to the medal. Of course we, and everyone in the trade, entirely acquits the firm of any intention to deceive, and no doubt our excellent contemporary has been the victim of a hoax, which, like most jokes of the kind, does good to no one, and is only calculated to arouse bad feeling.

The Vertical Feed Company and the recent Exhibitions

In our article under the heading " Sewing Machine Medals at the Health Exhibition " in our last issue, we pointed out that the only three companies which obtained gold medals at the Healtheries

were the Singer, Wheeler & Wilson, and the Wanzer. We also called attention to the fact that it was stated that a London sewing machine house was advertising in a foreign country that they

had received a gold medal from the jurors, although their name did not appear in the London Gazette Supplement. To some extent our contributor was perfectly correct in his statement, but he did

not state, as he certainly ought to have done, that the Vertical Feed Company (the Davis Sewing Machine Company, of Watertown, N.Y., U.S.), obtained a gold medal

at the London International and Universal Exhibition at the Crystal Palace, held a little earlier in the season, and that it was this triumph which

was being referred to in foreign journals. Although the full title of the exhibition was not given, our contributor was not justified in running away with the idea that by the words " London

International Exhibition " the " Healtheries " was meant. Our attention has been called to the omission. We have to express our regret that we unintentionally did an injustice to the Davis Sewing

Machine Company, or the Vertical Feed Company as it is called in England. The Vertical Feed Company, it should be mentioned, obtained a success at the Palace which was as unique as it was

deserved, and we are bound to say that many disinterested persons have expressed their surprise, and indeed disgust at the fact that it did not gain more favour at the Kensington

Exhibition. Everyone in the trade knows what a sound reliable machine the " Vertical Feed " is, and we feel sure that no one besides ourselves will be injured by the blunder into

which we were led.

*********************************************************

London International Health Exhibition

South Kensington

International Health Exhibition, London.The Exhibition will be opened by the President, His Royal Highness the Prince of Wales, on the 8th of May 1884.

The Vertical Feed Sewing Machine at The London International Health Exhibition

At Stand No. 1,218, there is really a most beautiful display of work done by this machine, the London offices of which are at 52, Queen Victoria Street, E.C.. We recently gave some description of the splendid style of embroidery, French folds, cording, felling, &c., which this machine performs, and at the Health Exhibition we were pleased to find a very tasteful display of the same kind of work, upon which we observed several ladies feasting their eyes. The stand is an attractive addition to the department occupied by sewing machines and it really must be confessed that, of all machinery or apparatus shown at the Exhibition, the sewing machines carry the palm, both for their beauty and interest. As stated, "the Vertical Feed Sewing Machine differs from all others in that the work is fed from above instead of from below, thus leaving a smooth surface for it to run upon. Owing to the peculiarity of its feed-motion, it will sew over any unevenness, and from the thinnest to the thickest materials without change either of stitch or tension, and without any assistance from the operator. Every variety of work can be done without tacking, thus effecting a great saving of trouble." The new high arm of this machine is worthy of special mention, whilst the under-view is very simple, and has no parts that require to be looked after.

*********************************************************

1885

The Vertical Feed Sewing Machine

The London manager of the Vertical Feed Sewing Machine Company, at 52, Queen Victoria-street, informs us that by the latest returns, this company has now 300.000 sewing machines in use throughout the world, of which 4.000 are running in England. They are used by the Auxiliary Forces Uniform and Equipment Company, at Limerick, with steam power, and do first class work at the rate of 1,500 stitches a minute. We have already spoken of the excellence of the Vertical Feed Machine, and the perfection and beauty of its work, and have pleasure in publishing the report of the judges of sewing machines at the Sydney exhibition, which is as follows : "We have carefully and minutely examined the whole multifarious exhibits in sewing machines, in most cases devoting an entire sitting to the exhibition and testing each type of exhibits, commencing with the American Court, and taking them as they stand in order in the gallery. The producers of the Vertical Feed Machine have departed from the general practice of manufacturers inasmuch as, first, placing the feed above the work, instead of underneath it, in such a manner as to obviate the objections which caused the abandonment of that system as originally produced. Second, the increased range of work which the above arrangement permits. This we find to be considerably in excess of that of the other system. Third, the extreme simplicity of its construction, the number of its working parts being greatly reduced in comparison with any other machine doing the same quality, of work, with a consequent decrease of wear and tear. Fourth, the workmanship is of the highest class. In conclusion, we have the honour to summarise our recommendations as follows:

— 1. Merit, the New Vertical Feed Sewing Machine being a complete departure from the ordinary style of sewing machines, possessing all the advantages of such ordinary machines, and in addition, an increased range of work, with the greatest simplicity of construction and reduction of number of working parts. We consider it to be entitled to the first place in awards.

Geo. H. Royce, C.E.,

Editor, Australian Engineer, Chairman.

After the close of the Sydney Exhibition, the exhibitors, we are informed, were invited to attend the Colonial Exhibition at Brisbane, Queensland. The sewing machine exhibitors availed themselves of the opportunity, and again the Vertical Feed Machine was awarded the only first prize. The following is another report, that of Jury 37, Melbourne International Exhibition.

The competition in sewing machines proved very keen, and great interest was evinced both by the representative of the makers and the public, in the result of the trial.

The machines were removed from the stand, and were submitted privately to the jury, and their various qualifications explained by skilled operators.

The jury then retained possession of them for some time, and at their leisure examined the workmanship and material, testing the latter for hardness by the use of a file.

Among domestic machines the highest place was awarded to a machine comparatively new in the Melbourne market, though by no means untried elsewhere, and known as the Davis Vertical Feed Sewing Machine.

The feed apparatus is entirely removed from the usual position beneath the table of the machine, and is attached to the head. It consists mainly of a vertical bar placed close to the presser foot, and which receives suitable vertical and horizontal motion from mechanism contained in the head of the machine. We find the other points entirely novel.

First—The presser foot, instead of being continuously urged downwards upon the work, is lifted lightly at the instant that the forward motion takes place.

Second—The feeding is accomplished while the needle is in its lowest position, and the needle partakes of the forward motion of the feed bar, pinning the two plies together, and causing both to advance equally.

The machine is also provided with a very complete series of adjustments for counteracting the effect of wear, and improved automatic bobbin winder, and in all its details is carefully and judiciously worked out.

Owing apparently to its peculiar feed motion the Vertical Feed Machine possesses an astonishing power of passing over seams and other irregularities, and accomplishes with the greatest ease a remarkably wide range of work. It is also provided with a very ingenious and novel set of attachments adapted to work in unison with the new feed motion, and enabling very complicated operations to be performed with facility, and in many cases dispensing altogether with the necessity of guiding the work by hand.

It was at first supposed by the jury that this excellent performance was in some measure due to the special skill of the operator. This view was, however, entirely negatived by the fact that a change of operators in no way impaired the result.

The Vertical Feed Machine is made for either foot or hand power, and performed equally well in each case.

To it the Jury awards the first order of merit, as being prominent for simplicity, convenience, efficiency, and rapidity, both as a treadle and hand machine.

W. C. Kernot, Chairman, Jury 37.

The result was that two gold medals were awarded Vertical Feed Sewing Machine Company, viz., one for the hand, and the other for the treadle machine. The same company also took the first prize for their machine at Adelaide.

1887 London American Exhibition

Awards at the American Exhibition

The Davis Vertical-Feed Sewing Machine Company have booked space at the American Exhibition, and we understand from their courteous European manager, Mr. George W. Phillips, that their stand will be an attractive one.

The Committee of Awards at the American Exhibition tendered the following decisions :

The Davis Vertical Sewing Machine Co., Watertown, N. Y. For the best domestic sewing machine.

*********************************************************

Messrs. McLean, Bros., & Rigg, of Adelaide, are the sole agents for the Davis vertical feed machine, which they have exhibited at all the exhibitions in the Australian Colonies of recent years, and obtained first prizes. The price of the treadle machine has been reduced £1 recently.

At the Adelaide Exhibition (1887-88) the sewing machine trade is not very extensively represented. Not a single English machine firm, other than the Singer Company, is present. The " Flora " Toy Machine is on show. Among the Americans present are the Davis' Vertical Feed and the White Company.

The Vertical Feed Company have recently received at the Adelaide Exhibition (1887-88) the Diploma of Honour, and at the Toulouse Exhibition a gold medal.

sources :

Watertown NY Daily Times

Sewing Machine Gazette

The Encyclopedia of Antique Sewing Machines, 3rd Edition

https://jeffco.wikispaces.com/Davis+Sewing+Machine+Company

Smithsonian Institution

History of Jefferson County, by John A. Haddock

ISMACS