- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

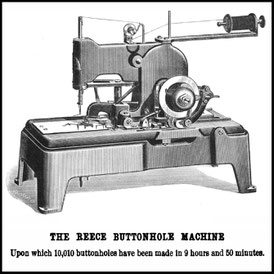

THE REECE BUTTONHOLE MACHINE

by Scientific American

Of all the exhibits at the World's Fair there is none that attracts more attention than that of the Reece Buttonhole Machine Company, of Boston. exhibit is in Machinery Hall and they also exhibit and do all the buttonhole work in the Model Shoe Factory in the special Shoe and Leather building. In this building shoe manufacture is practically exemplified as carried on in the leading shoe factories of the country, a thousand pairs a day being made and the improved machinery used, including all the best machines which have been practically successful. The introduction of the Reece machine in shoe factories effected a saving in manufacture of from 40 to 50 cents a case. The machines manufactured by the Reece Buttonhole Machine Company have been in practical use throughout the world for the past ten years and their introduction in the trade reduced the expense of buttonholes 75 per cent. The buttonhole machines put out by this company were the first machines to automatically cut, stitch and bar a buttonhole, reducing the labor of the operator to simply the moving and clamping of the material. The stitching mechanism is rotated about the eye, thereby saving any turning of the fabric which is being stitched and the movements of the machine are all easy uniform and positive and no important movements are dependent upon springs; the stitching mechanism is very simple, consisting of a looper and needle below the cloth plate and a needle above said plate. These parts receive their movement from a compound eccentric and they make a complete buttonhole or purl stitch for each reciprocation of the needle bar, which makes the machine capable of running at a high rate of speed as well as noiseless and durable. The buttonhole is automatically cut and transferred from cutter to stitcher by an even, uniform movement, avoiding any jar or blow.

The starting and stopping of the stitching mechanism at the commencement and finish of the buttonhole are automatic, the needles always stopping out of the fabric. The machine runs equally well on all kinds of materials, either with silk or cotton thread. The company has on exhibition machines for making eyelet holes and buttonholes of various styles required by the different trades, such as boots and shoes, clothing, collars and cuffs, underwear and, in fact, everything that requires a worked buttonhole and they have at least five different methods of barring the small end of the buttonhole, each of which is equally well adapted to its particular line of work. When it is taken into consideration that at the time the Reece buttonhole machine was invented it required thirty-five hand movements to make a buttonhole on the best organized machine and that the introduction of the Reece machine reduced this to two hand movements, the magnitude and importance of this invention can be more fully appreciated. The latest production of the company is a buttonhole machine that makes any size buttonhole, from a round eyelet, such as is used in a shirt front, to a buttonhole two inches long, used in ladies' cloaks. The invention of this machine has greatly simplified the mechanism and reduced the labor of the operator to one-half what it previously was, the production being correspondingly increased.

The machine is entirely automatic and requires no labor on the part of the operator, such as closing the work clamp by the foot or hand, as in the previous Reece machines, reducing the labor to simply moving the material from one to the next buttonhole. A series of any number of buttonholes can be cut, stitched and barred without the operator moving her hands from the material and without any movement of the foot. This machine is the first ever produced that barred the buttonhole with a purl bar, which makes the small end of the buttonhole in harmony with and equally as neat as the sides and crosses the stay cord and firmly stitches it together, so that there is no possibility of its starting.

The company has also put upon the market for the past five years a machine for stitching down the thrum ends and stay cord between adjacent buttonholes on shoes by a blind stitch. These machines are entirely new and opened a new field for sewing machines, as this work had always been done by hand. One of these machines and an operator now take the place of ten hand operators and the work is far superior to that done by hand, making a neat, uniform finish on the inside of the shoe.