- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

Room 21

Shoe Making

Old and New

by Fred A. Gannon

1911

A short history of the American Shoe Manufacturing Industry. The marvelous progress that has been made

SYNOPSIS OF CHAPTERS

Part 1. First shoes and shoemakers in America. Indians and moccasins. First shoemakers came on Mayflower.

Part 2. Colonial shoemakers. Their hard struggle for existence. Shoemakers cut hair, pulled teeth and did other things.

Part 3. The time of the "Ten Footers." Shoemakers used the lap stone and flat face hammer.

Part 4. Union store period. Shoemakers were paid in groceries and dragged them home in a cart.

Part 5. Story of Ebenezer Breed, who established the protective tariff on shoes, and died in an almshouse.

Part 6. Howe's great invention of the sewing machine. His dream of what his genius failed to discover.

Part 7. John B. Nichols made the Howe machine sew leather.

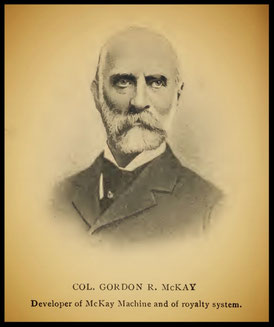

Part 8. Blake's great invention of the McKay machine, and the revolution in shoemaking that it caused.

Part 9. The story of the lasting machine, showing how a genius from Dutch Guiana revolutionized the lasting of American shoes.

Part 10. The general development of machinery, Including the Goodyear machine and the pegging machine, and the benefits from it.

Part 11. American leather making. The story of the chrome process.

Part 12. Organization of the factory system, showing how the individual workman became a part of an organization and how he was benefitted.

Part 13. The Greater New England movement.

Part 14. Organization of the machinery system of shoemaking by the U. S. M. Co. and its benefits to the trade and the people.

Part 15. Development of transportation of shoes from the time of the "bag boss" to modern swift express service.

Part 16. Development of shoe styles from colonial to 20th century fashions, the use of blacking, of laces and buttons and the development of the modern repair business.

Part 17. Clogs, pattens and galoshes and modern rubbers. The story of Goodyear's invention of the method of vulcanizing rubber.

PART I

In the manufacture of boots and shoes the United States is the foremost nation in the world today. The industry of making boots and shoes is among the most important industries of the nation today and it is also among the oldest. An inquiry into the rise of the industry from its humble beginnings of colonial times to its splendid prosperous, but, very complex state, of today, reveals some interesting changes in commercial and social life, as well as in the mechanics and economics of manufacturing. The first white people in this country of course brought over their boots and shoes from the European mother countries, and they were for a long time dependent upon the mother countries for additional supplies of footwear. There were, in the first days of the settlements, no big factories, such as there are today, nor even any little shoe shops or “ten footers,” as the shops occupied by the old fashioned hand shoemakers were called. The colonists found only forests and wild lands inhabited by Indians and animals. The Indians made leather by primative processes and they used the leather for their garments and

3

wigwams. They sewed two or three pieces of leather together to make a sock, called a moccasin. Pioneers among the white men put on me moccasins of the Indians and used leather tanned by Indians for making hunting shirts, trousers and leggings. Some of the settlers in the towns wore footwear and clothing of leather made by the Indians, when supplies from Europe were scant. The American shoe manufacturing industry appears to have had' its beginning in Salem, Massachusetts. Thomas Beard and Isaac Rickerman settled in Salem in 1629, coming on the Mayflower, on her second voyage. They were shoemakers by trade and they are the first shoemakers of record in this country. Philip Kertland, a shoemaker, settled in Lynn in 1635 and was the first shoemaker in that now celebrated shoe manufacturing city. The shoemakers who came to this country in its early day were most welcome men. The rough lands of the new country, broken only by rude roads and paths, wore out quickly even the strongest boots. It was difficult to get new boots for it was necessary to send to Europe for them, until the shoemakers came. Beard and Rickerman were considered so valuable to the colony at Salem that they were to have their board and houseroom at the expense of the colony. Kertland was granted

4

ten acres of land by Lynn. The little town of Reading, in Massachusetts, granted its first shoemaker ''rights to wood and herbage, meaning that he could gather from the town lands such wood as he wished for fuel and herbs as he wished for medicine without cost. These early shoemakers brought over "the art and mystery of shoemaking,'' as the trade was called in colonial times. They brought it from Europe as a trade new to this land, but ancient in Europe. Beginnings of this "art and mystery of shoemaking" may be traced even back to ancient Egypt, for methods of some of the Egyptian shoemakers, as pictured on the walls of tombs at Thebes correspond to methods of the hand shoemakers of former days in this country. The new industry was very slow in starting in this country but after it once had a good start it flourished mightily, and it accomplished more in a few years for the men engaged in it, as well as for the world at large, than had been accomplished in Europe in more than 2000 years. The shoe industry in this country has so prospered that the United States now makes about $ 500.000.000 worth of boots and shoes annually. It produces about 300,000,000 pairs, which averages about three pairs to each person in the country. It sells $ 10.000.000 worth of shoes to foreign countries each year. It provides people with the best footwear at

5

the lowest prices that they ever have had. The rise of the American shoe industry from its small beginnings to its present splendid position makes one of the most interesting chapters in industrial history.

6

PART II

The first shoemakers in the colonies, though most welcome, found a very poor market for products of their skill. People needed shoes, it is true, but there were only a few people in the colonies, and they were spread out along the entire Atlantic Coast among the 13 colonies, in little settlements, and in isolated cabins in clearings of the forest. New England was the manufacturing section of the colonies, and, naturally, led in shoe manufacturing. There were some Dutch shoemakers in New York. The Southern colonies were agricultural communities and they depended largely upon the artisans of New England and of Europe for their manufactured goods of all kinds. The struggle for existence was keen in colonial days. Necessity compelled settlers to become jacks of all trades. The farmer often tanned hides and skins from his own cattle, or from beasts of the field, which he hunted. He hunted deer, bear, and the wolf for their flesh for food. He used for tanning the pelts bark from trees close by his cabin. He sank a hogshead or an old boat, or box, in his yard for a vat. Sometimes he cut up this leather and made it into garments,

7

coats and trousers too, as well as boots and shoes. Many of the first shoemakers found insufficient employment in the settlements. There were not enough people to buy their shoes to keep them busy all the time. Some of these shoemakers became jacks of all trades while others became travelling shoemakers. The jack of all trades undertook to sharpen knives, saws and axes, and to mend furniture, tinker clocks, teach singing, cut hair, and even to pull teeth, for the shoemaker was the only person in the settlement who had pincers. Thomas Bowler, of Lynn, combined the tasks of town clerk with those of shoemaker. He charged ten cents an hour for his work as town clerk, for that was the amount he earned as a shoemaker. The traveling shoemaker packed his kit, and his stock of leather in a bag, threw the bag over his shoulder, and walked from settlement to settlement, seeking work. He was warmly received at many an isolated home. Not only did he bring the means of providing new footwear, and of mending the old, but he also brought the news and gossip of the time, which he cheerfully dispensed and discussed, as he sat in the warm chimney place and worked over his last, with the settler and his family gathered around him. The kit of the colonial shoemaker was necessarily quite simple. He had a flat face hammer and an awl and pincers and

8

knives, which he brought from England with him, a lap stone that was picked up on the seashore, some hand forged nails, some linen thread spun perhaps by housewives of New England, some wax from the bee hives of colonial farms, and leather imported from Europe or possibly made by some early tanner. His product was crude, for he had only crude tools and materials with which to work. The leather was rough and heavy. It was bark tanned. It was stuffed with oil from fish of the sea, which was quite plentiful in colonial times, since the seafaring men made oil for export to Europe. But the leather was not glazed, or polished, as is leather of to-day. The shoes made by the colonial shoemakers, though not handsome, were strong and serviceable, and well endured the hard wear which they got on the rough roads. As the colonies increased in wealth and population, the well-to-do people called for fine shoes. For them, some fine shoes were imported from London, and Paris. A few enterprising shoemakers imported fine leather from abroad, and made stylish shoes, particularly buckled slippers for the beaux, and dancing slippers for the belles.

9

PART III

Shoemaking was a picturesque industry in the first half of the 19th century. Whittier portrayed some interesting aspects of it in his ''Cobbler Keezar" and other poems. The typical shoe shop of New England of a century ago was a wooden building ten feet square, or the size of a small living room in a house of today. It had one room with a stud of six and one half feet so that a tall shoemaker had to take off his hat when entering it. It also had a garret in which was kept a wonderful miscellany of discarded articles such as old lasts and tools, umbrellas, broken clocks, chairs, candle riggers, old boots and shoes and other trumpery. The old time shoemaker religiously believed that everything came into use again once in seven years, and so saved everything. Such shops as there were, were scattered over New England in the farming regions as well as in the manufacturing centers. It was a common practice for a farmer to till his farm in the summer time and to spend his winter making shoes, or for a fisherman to fish in the summer time and make shoes in the winter.

10

The interior of a shoe shop of a century ago would amuse a shoemaker of today. On the sunny side was the shoemaker's bench or seat. The salamander stove was in the middle. Leather tubs for soaking soles and miscellaneous supplies were scattered over the floor. A couple of extra chairs were placed for the convenience of visitors. On the wall was a battered clock, a notice of a political meeting or picture of the cobbler's favorite candidate. The shoemaker worked “on a seat” or a low stool, having a low bench attached to it to provide room for his kit. The "seat" corresponded to the “seat” on which the cobbler of today works. Sometimes shoemakers shared a shop. Then it was a problem to divide up the room evenly and to place each man so that he would not strike his neighbour when he “swung out” with his waxed ends in sewing a shoe. The first shops were heated by an open fire-place. When stoves became common shoemakers set them up in their shops. They showed favor for the style of stove called "the salamander. But the shops were loosely built, and it was a difficult matter to get them comfortably warm even with the hottest kind of a fire. Some shoemakers crept so close to the fire to keep warm that they actually wore "shin boards'' to prevent the flames from scorching their legs. Yet the cold winds

11

pierced through the cracks in the doors, windows and walls, and struck the shoemaker in the back and made him shiver. Of course, in the summer time the old fashioned shoe shop with its leaky walls was comfortable. It is a tradition that shoemakers on very cold days used to debate whether it would cost more to heat the shop than they could earn. To decide the problem an unlucky apprentice lad was captured and set down onto a wet lap stone. If he froze to the stone it was too cold to work. So the shoemaker went home, either to play cards by the fireside or to get a gun and go hunting Johnson says in his "Sketches of Lynn" that the following tools and appliances were regarded as necessary by the old fashioned shoemaker : "A lap stone, hammer, stirrup, whet board, pincers, nippers, shoulder stick, long stick, pettibois, toe-stick, fender, bead, scraper, knives of different sorts, such as skiver, paring off knife, heel knife, etc., awl, bristles, tacks, beeswax, a piece of sponge, paste horn, bottle for blacking, gum and acid, chalk, dog fish skin, stitch rag, grease, channel-opener and apron". The shoemaker of today would be quite as much at loss to handle all these old fashioned tools as would be the cordwainer of a century ago to operate the machinery of factories today.

12

The lap stone of the old time shoemaker was sometimes selected from the stones of a neighboring beach or field, or in rare cases, it might have been secured by the shoemaker in some foreign land that he visited when he was a sailor before the mast. The stirrup, a leather strap, was primarily intended for use in strapping a shoe to the last, but it frequently served as a means for disciplining or stimulating the training of an apprentice. Some jocose shoemakers pasted a sign on the wall of their shop reading ''Strap Oil for Sale Here." When a small boy of a century ago was told to go to the shoemakers for some strap oil he foresaw that a painful scene was to be enacted in the woodshed. Colonial shoemakers often took pay for their work in corn, beaver skins, wampum or any other commodity that served as a substitute for money in the colonial days, when real money was scarce. Towards the close of the colonial period wages of shoemakers rose as high as 70 cents a day, in cash. Today, shoemakers of high skill can sometimes earn 70 cents an hour. The General Court of Massachusetts undertook to regulate the industry of shoemaking. At one time it forbade tanners to make shoes, or shoemakers to make leather on the ground that a man should not have two trades, lest he injure another man. In the colony of New York there was actually prosecution of tanners

13

and shoemakers for maintaining a monopoly. The General Court of Massachusetts also forbade persons of mean estate, or scant wealth, to wear great boots, or other expensive footwear. This law was intended to prevent extravagance in dress by people who could not afford rich apparel. James Everell was a great shoemaker in Boston along in 1650. He employed several journeymen to work for him. He made fine boots and shoes for the wealthy merchants of Boston, and for the crown officers, and their families. He made some second grade shoes which were sold as ready made shoes to the poorer folk of the town and colony. It is tradition that he even exported shoes. Everell owned the property that is now bounded by Hanover, Elm and Union streets in Boston. He secured from the town officials a permission to sink pits, “to water his leather in". He acquired much wealth for his time. He was a pioneer in making Boston an important shoe centre. He served as selectman of the town. One of the first transactions in boots and shoes in the new country occurred in 1623, when Gov. Bradford, and others of the Plymouth colony, formed a syndicate and raised $ 250, and sent Isaac Ellerton to England to buy shoes, stockings and cloth.

14

PART IV

Real cash was scarce a century ago and credits were long. New England shoe manufacturers sold their shoes to the South and the West, as far as it was settled, on six, and even on nine months' credit. Sometimes they accepted wheat, tobacco, sugar, cotton, or other commodities in payment for their shoes. As shoe manufacturers received cash for their goods only in small quantities, they were able to pay their employees only small wages, and those wages quite infrequently. It was a common practice for a shoe manufacturer of 60 or 70 years ago to get his employes to trust him for their wages, until he could sell his shoes for cash. Then he would pay them their total wages, and a premium besides. If he lost on his venture his employes lost on their wages. A successful Marblehead, Mass., shoe manufacturer got his start by cutting shoes on top of a pork barrel in his grocery store, and by getting his customers to make his shoes he paid them in groceries. In Lynn, the practice of paying shoemakers with orders on a store was developed to a considerable extent. The Union Store,

15

a noted store of 1830, was established and carried on by a group of Lynn manufacturers. It was stocked with goods of all kinds, indeed, with everything that a man might need in daily life. Shoe manufacturers who were interested in this store, gave their employes, when they brought in their manufactured shoes each Saturday afternoon, orders on the store in payment of wages. Each order read "Please deliver to the bearer goods to the amount of ". The amount was never large, for wages of shoemakers of 1830 ranged from $ 5 to $ 7 a week, when they were paid in orders. A man who insisted on cash payments of his wages usually had a great deal of difficulty in finding employment. The orders went into circulation, for shoemakers used them to pay for goods that they bought at stores other than the Union Store, and to pay the doctor, the druggist and others. The orders were accepted as worth 60 or 70 per cent of their face value, when in general circulation, but were worth their full face value, in exchange for goods at the Union Store. Fortunately, necessities of life were very cheap 80 years ago. So a shoemaker who brought in his week's work, and got an order on the store in payment for his wages, was usually able to exchange that order for enough goods to keep himself and his family alive for the week.

16

It was common for the shoemaker to fetch to the factory the shoes that he had made during the week in a bag, or a basket, often the family laundry basket, or even in a wheel barrow, or a cart made by placing a soap box on solid wooden wheels. This cart he loaded up for his trip back home with leather and supplies for his next week's work, and with his supplies that he got at the store in exchange for his order. The supplies often consisted of a few pounds of corn meal and a little molasses, tea or coffee, a salt fish, some sugar, a piece of butter, a few yards of cloth, a new hat, or a piece of crockery. Necessities of life were very scant indeed a century ago. Men knew what it was to go hungry. But they struggled on, courageously seeking better times, and manfully building the foundation of the prosperity that is enjoyed by their successors today. There were many pleasant hours in the life of the shoemaker of a century ago. The occupation of shoemaking was agreeable to many, because a man could read from an open book by his side, or discuss political topics of the day with friends, as he made shoes. These facilities for improving the mind were taken advantage of by many shoemakers. Roger Sherman studied from an open book as he made shoes, and so did Henry Wilson, ''The Natick Cobbler”. Shoemakers who lacked

17

ambition to profitably employ their leisure time found many ways to idle away the hours. Haverhill shoemakers had a curious schedule of days for absenting themselves from their tasks of shoemaking. In April, the Haverhill shoemaker would go out one day and sun himself on a bank. It was his spring medicine. In May, he would take a day to plant his garden, and in June a day to hoe it. In July, he would make hay for his cow; in August he would pick berries; in September go to the shore for a clam bake, and in the winter months he would go gunning frequently. Once a Haverhill shoemaker felt that he wanted a day off, no power known to the employers of the time could induce him to work. In Lynn, almost every shoemaker kept a pig. The slaughter of the pig was quite a ceremony. The shoemaker and his friends celebrated the event as a holiday. The pork was packed away for use in the winter time. Many Lynn shoemakers lived on their pork, on dandelions from the field and on clams and fish from the harbor, during the panic of 1837, when there was no work for them. The introduction and use of shoe machinery, and the development of the factory system, led to increase in wages, shortening of hours of labor, and improvement of product.

18

PART V

After the Revolution, the new nation began to prosper. But its shoe manufacturers could not get a start in their efforts to develop their business. They had improved the quality and appearance of their shoes so much that the newspapers of the time declared American made shoes superior to the best, imported shoes and advised American people to buy the home product as a patriotic duty. But a habit once established, good or bad, is difficult to abandon, and the American people kept on wearing many imported shoes. The future looked dark for the American shoe manufacturing industry. At the critical moment, the first great leader of the American shoe manufacturing industry appeared on the scene. This man, Ebenezer Breed, proposed that Congress should put upon imported boots and shoes a tariff that would keep them out of this country, until American

19

shoe manufacturers got opportunity to develop their business, and to prove to the American people that the American made shoes were best. After much agitation of his idea he convinced Congress of its merit, and a tariff was placed on the American shoe industry, and it remains in force even to this day. Behind this protective tariff the American shoe manufacturing industry has prospered in a way that has amazed the shoe trade of the world. Breed's career was dramatic. He was born in Lynn, Mass., the son of Quaker parents. He learned the shoe trade. When a young man, he went to Philadelphia, then the capital of the nation. There, his Quaker faith admitted him to the best society. During his stay in Philadelphia, he made the proposition that a tariff be placed on boots and shoes. Leading people of Philadelphia, to whom he argued his plan, agreed to help him. He gave a big dinner, to which he invited leading members of Congress and prominent citizens of Philadelphia. The brilliant Dolly Madison was there. During the dinner, he made a grandiloquent speech. A fragment of it is preserved to-day. Soon after the dinner, Congress placed a protective tariff on boots and shoes. Breed, who engaged in the wholesale boot and shoe industry, prospered much. He became one of the early great American merchants. He went to England where he was received by King George and Queen Charlotte. West, the painter, gave him a platter with his own portrait upon it. He visited Paris, too, but there he hid one day in a cellar until the riot and bloodshed

20

of a sad 24 hours in the French revolution had passed. Breed returned home. He made a tour of triumph of his country. He was feted everywhere, but he quickly fell to the depths of despair. He loved a Quakeress. Her parents refused to permit his attentions. They declared that he drank liquors while in Europe in violation of the temperance principles of the Quakers. He tried to drown his sorrow in the wine cup, and he drank it to the very dregs. He lost his business, his property and even his eyesight. He made his way a broken, blinded man to the almshouse in his native town of Lynn. Some kind person taught him to make shoes. He made them as best his sightless eyes would let him. Some of them he sent to Dolly Madison and other friends of his prosperous days. They remembered him with gifts. He became a gentle man again. The children learned to love him and to call him ''Uncle Eben" and to lead him along the streets as he went on visits to friends. One little girl brought him baskets of dainties from her mother's kitchen. Her mother was the Quakeress whom Breed had loved. The man who was so powerful as to build up a great wall of protection about the entire American shoe trade spent his declining days quietly and peacefully in an almshouse, forgotten by nearly everyone but the Quakers.

21

PART VI

Up to the middle of the 19th century the uppers of shoes were stitched at home by hand. The operation was called "binding shoes." Lucy Larcom made it famous in her poem, "Hannah at the Window Binding Shoes." Housekeepers in the shoe towns commonly kept a lot of shoes in the kitchen, and when they sat down to rest during the routine of household duties, they picked up shoes and sewed them to improve their moments. Wives and daughters of shoemakers commonly "bound" shoes for the breadwinner of the family. Dependent women "bound" shoes in order to earn their daily bread. By working all day they were able to earn 50 or 75 cents. The work was tedious and it hurt the eyes. But it was very necessary, for shoe manufacturers had much difficulty in getting shoes enough sewed to satisfy the wants of their customers. In the homes of some prosperous manufacturers it was the custom for wives and daughters and household servants to sit down for half an hour after dinner each day and "bind shoes." Along in 1850 these things were changed. The sewing machine, invented by Howe, was adapted to the sewing of leather by Nichols,

22

and the occupation of "binding" shoes ceased to flourish. Elias Howe was a workman in a Cambridge machine shop where he had come from his boyhood farm home at Spencer, Mass. He was of a family of inventors. It occurred to him one night, as he watched his patient wife toiling with the family sewing, that he might build a machine that would help her. His idea was not new. Patents on a sewing machine had been taken out in England as early as 1750. Napoleon had offered a rich reward to any inventor who would make a machine that would sew shoes. He wanted the shoes for his soldiers so that they could march and fight better. Howe wanted a sewing machine to help his wife in her daily work. Napoleon failed; Howe won. Howe had a desperate struggle. He began to work on his ideas of a sewing machine evenings after his day's work in the factory was done. He became so fascinated with his dream of a sewing machine that he gave up his place in the factory and devoted nearly all his time to working on his wonderful invention, sparing from it only enough time to do odd jobs in machinery or to pawn some household possession, so as to provide himself and family with daily bread. But they often suffered hunger and want. After eight years' labor he built a machine which took stitches. It is a pretty tradition that one night, defeated in all his endeavors and at his wit's end, he threw himself down to restless sleep. He dreamed that

23

he was seized by a tribe of strange people whose king commanded him to stitch him a garment upon his sewing machine upon pain of instant death. His machine refused to stitch. Guards seized him to execute him. He noticed that their spears had holes near their points, not at their butts. Instantly it game to him that the eye of the needle of the sewing machine should be at its point, not at its butt, as in the ordinary needle. He made a needle with the eye near the point, and his sewing machine became a success. But success had not yet come to Howe. Nobody believed in his invention. He could secure no money with which to build and market his machine, despite the fact that it was one of the most valuable machines in the world's history. He had to take a position as a railroad engineer to earn his living. He was tempted to accept an offer from England for $1250 for the English rights to his patents and a position at $15 a week. The position in England was disagreeable to him. He returned home, pawning the model of his sewing machine to get money enough to pay his passage. When he arrived in New York he learned that his beloved wife had died of consumption and that shrewd machinery companies had seized upon his invention and were putting sewing machines upon the market. He borrowed money, brought suit against those who had infringed his patents, and won a victory. From

24

this time on his career was one of much prosperity. Companies making sewing machines had to pay him royalties, and at one time he was receiving $4000 a day in royalty payments. He enlisted in the Union army during the war as a private. The paymaster was slow in coming round. One day Howe disappeared from camp. He returned the next day with a big box, from which he paid off the entire regiment. For his invention he was awarded the cross of the Legion of Honor of France. He died in 1867.

25

PART VII

An early advertisement of sewing machines, published by I. M. Singer & Co., in a Boston newspaper in 1851, attracted the attention of a young shoemaker, John Brooks Nichols, of Lynn. He was born in Wakefield, February 8, 1823. He learned the trade of shoe cutting of his cousin Thomas Bancroft, who had a shop in the basement of the Congregational church close by Lynn Common. After two years as a shoe cutter, he bought a retail store in Cambridge. This venture failed. Then he saw the advertisement of the sewing machines. Mr. Nichols, an ambitious young man, was seeking some opening with a bright future. He decided that the sewing machine would become of great value. So he bought one of the first lot of 25 machines that I. M. Singer & Co. made. This machine, Mr. Nichols set up in a shop on Sudbury street, Boston. He established a contract stitching business, stitching pantaloons on the machine. At the time, the sewing machine had not been perfected for use in stitching leather. Mr. Nichols, a shoemaker by trade, naturally wondered why the machine couldn't be made to stitch leather.

26

He began to experiment, using scraps of kid leather that he brought from Lynn shoe factories. He found that his sewing machine wouldn't stitch leather neatly because the needle was bigger than the thread. The seams were loose and the stitches coarse. But he was of the opinion that his machine could be made to stitch leather as nicely as did the "binders.'' To make it do so, he got around to his shop one and one-half hours ahead of time in the morning, and he left it one and one-half hours late, putting in the extra time in his attempts to make his machine stitch leather. Finding that the needle was too large, he went to the needle manufacturers and got them to make needles of new shapes and sizes. These needles he filed, and even smoothed down with emery paper to get them of the desired small size. He also went to the manufacturers of silk and cotton threads, and got them to make new kinds of thread for his experiments. After months of patient labor, he succeeded in stitching leather on the machine so that its stitches compared favourably with the stitches of the shoe binders. I. M. Singer & Co. undertook to put onto the market machines for stitching shoes. They sold to three Lynn manufacturers (Scudder Moore, John Wooldredge and Walter Keene), rights to use the

27

machine for stitching leather in Essex County. Mr. Nichols became instructor of operators on the machines used by these firms. He was paid $3 a day for his services, which was twice the wage that he ever received before, and a wonderfully high wage for the time. Mr. Nichols decided that he would himself start a contract stitching shop. The three manufacturers who had purchased the exclusive rights to use Singer machines for stitching shoes in Essex County protested to the Singer Co. against Mr. Nichols starting in business. The Singer Co. declined to let Mr. Nichols have any machines. But he secured a Singer machine that the Singer Company had sold to his cousin, Thomas Bancroft, before they made their exclusive agreement with the three manufacturers. This machine he remodelled so that he was able to use it for stitching shoes. At this time Mr. Nichols first heard of Elias Howe. Howe was just home from his unhappy European trip, and was laying claim to his patent rights. Mr. Nichols went to him in Cambridge and asked for permission to make use of his invention in stitching shoes. Mr. Howe replied that Mr. Nichols was the first man who had asked permission to use his invention. He furthermore said that William R. Bliss, a Worcester shoe manufacturer, had the rights to use the invention for stitching

28

leather. Mr. Bliss was one of the good friends who provided Howe with money to fight for his patent rights. Mr. Nichols joined interests with Howe and Bliss. Howe, with money provided by Bliss, succeeded in putting a line of sewing machines on the market. These machines were called the Howe improved machine. They were built on designs prepared by Mr. Nichols. The profit on these machines enabled Howe to employ counsel and to fight his patent suits to a successful finish. Mr. Nichols continued in the machinery business as a partner in the firm of Nichols, Bliss & Co. and later of Nichols, Leavitt & Co. When the sewing machine was new, shoe manufacturers used to visit the Nichols & Bliss store in Boston, inspect the machine and say that it was necessary to give them a practical demonstration. So he employed shoe stitchers to operate the machines in the Boston store. When shoe manufacturers came in and saw the machines sewing shoes they decided that they must have them, and they bought. Mr. Nichols demonstrated the machine in several communities. In one place, shoemakers, both men and women, crowded around the machine. Mr. Nichols made it run splendidly. The next morning a shoe binder sent word to him that she ''would like to hang him to a sour apple tree because his machine would take her work

29

away from her." She did not foresee that the machine would save her labor and add to her wages. Mr. Nichols retired from business many years ago. On Feb. 8, 1910, he passed his 87th birthday pleasantly at his home in Lynn. He is a remarkably alert and active for a man of his years.

30

PART VIII

When the Civil War broke out, the government at Washington was perplexed to provide shoes for the army. So many shoemakers had left their benches to volunteer that there were not enough at home to make sufficient shoes for the army. Some shoemakers left their unfinished shoes on the bench as Putnam left his plow in the furrow. Some manufacturers rode around New England towns waving rolls of bills, and offering premiums to those shoemakers who would stay a while longer and finish up the shoes in the factory. But the shoemakers marched off to war and there weren't enough left behind to make shoes for the soldiers, to say nothing of the other people of the country. Prices of shoes rose rapidly. Congress considered the matter of taking the tariff off boots and shoes, the tariff that Breed had won, so that large quantities of European shoes might be brought in to make up the threatened deficiency in the American supply. A crisis was at hand in the American shoe manufacturing industry. But, as has always happened in this great nation, the right man with the right idea

31

appeared at the right moment. Col. Gordon McKay brought out his sewing machine, an invention so wonderful that one machine took the place of a whole company of shoemakers who had gone to war. This machine was invented by Lyman R. Blake, a young man of South Abington, a little town on the South Shore of Massachusetts, where he was born August 24, 1835. When a boy he began to work in a shoe factory during his school vacations. Before he was 21 years old he had saved $1400 from his wages, and this sum he invested in a shoe manufacturing firm, of which he became a partner. To improve the business of his company he conceived the idea of making a machine that would sew the soles of shoes to the uppers, just as the Howe machine sewed the uppers together. His partners thought the idea somewhat dreamy, and insisted that if he worked on it, he should work on it only after factory hours, and should spend only his own money on it. Blake went ahead on these terms. Evenings, after finishing his day in the factory, he drew his designs and whittled out his model. He made a wooden machine that looked to him as if it would sew shoes. He got the village wheelwright to make him moulds, and from them he had parts of a metal machine cast. He put the machine together and found that it would sew shoes.

32

But he realized that he had a machine that was too big for his business experience. His patent attorney introduced him to Col. Gordon McKay, a machinery manufacturer of experience and ability. Col. McKay agreed to buy Blake's invention, giving him for it $ 8.000 in cash and $ 62.000 in notes, to be paid from the profits of the company. Col. McKay started to develop the machine. Blake took his $ 8.000 in cash and went to Staunton, Va., where he established a retail shoe store. He had hardly opened the store when the war broke out. He came North on the last train out, leaving his stock behind him. His return home was most timely. McKay was having a great deal of trouble with his machine, even though he had employed to perfect it the ablest mechanical engineers that money could secure. Blake was the sole master of the machine, however. He perfected it, and made it sew shoes, and he taught others how to make it sew shoes. The machines were set up in shoe factories in New England towns to take the place of the shoemakers who had gone to war. Soon the shoemaker soldiers at the front received the McKay shoes. They looked upon them in wonder, realizing that the shoes were not sewed by hand alone, and yet being unwilling to believe that it was possible to build a machine that would sew shoes.

33

PART IX

For a score of years after it was proven practical and profitable to sew shoes by machinery, it was necessary to last shoes by hand. Inventors burned barrels of midnight oil and promotors spent hundreds of thousands of dollars in endeavors to change the methods of lasting shoes from hand to machine, as Blake and McKay had changed the methods of sewing shoes. Manufacturers had McKay machines and other machines in their factories, but their lasting rooms were occupied by hand workmen. The lasters were very strongly organized and their unions strictly regulated their occupation, limiting the number of apprentices and insisting upon and securing a very high wage. Indeed, the hand lasters were commonly looked upon as princes among shoemakers. Their wages ranged from $ 20 to $ 40 a week, and at times even $ 50. Most of the lasters were proud of their position in the trade even to vain boasting. It is tradition that, in a Lynn factory one day, a laster boasted: "No matter if the McKay machine is a wonderful machine, no man can build a machine that will

34

take the job of the laster until he can make a machine that has fingers like a laster, and that's impossible". The boast fell upon the ears of J. W. Matzeliger, an operator of a McKay machine. This young man came to Lynn from Dutch Guiana, where he was born, the son of a Dutch engineer. He was educated in the government machine shops. He came to this country when a young man and obtained a position in a Lynn shoe factory. His mechanically trained mind naturally bent itself upon ideas of improving the McKay machine. But when he heard the boast of the laster that no machine could possibly be built to last shoes, he thought of the possibility of building such a machine. He went to work secretly on his plan, for the shoemakers of his time were very strongly opposed to machinery. They thought it took work away, from men. The lasters, in particular, dreaded any attempts to build a machine to last shoes. Matzeliger established a little experimental shop over the West Lynn mission. There he toiled each night, after completing his day's work in the shoe factory. His machine became his idol. He spent all his money in building it. Yet he was so short of money that at times he picked up bits of wood and old cigar boxes from the street and used them in making his model. His first machine was a disappointment, to himself, and to

35

those who looked at it. One inventor, who was also working on a lasting machine, offered him $ 50 for his model. Matzeliger concluded that if the model was worth $ 50 to another person, it was worth more than that to himself. So he kept it. He went to work to build another model. Unhappily for Matzeliger, his secret leaked out. His fellow workers laughed at him as a dreamer, and the lasters jeered at him. They did not foresee the splendid results his work would bring to them. Matzeliger's second model was also a failure. But it was so much of an improvement over the first that a machinery man offered him $ 1.500 for it. Again he decided that if the model was worth something to another person it was worth more to himself, and he kept it . He set out to build a third machine. This third model was so satisfactory that Lynn men, who inspected it, advanced Matzeliger money with which to build a fourth model. This model was the foundation of the present consolidated lasting machine. Matzeliger was exhausted by his efforts to build the machine, and was unused to the New England climate. His health failed him in the midst of his work on the fourth model, and he died before he completed it. But others saw the merit of his invention and completed his model. The machine was put upon

36

the market. It was set up in shoe factories, where it took the place of hand lasters. They struck against it. A bitter fight was carried on for a while. Some of the lasters said that the machine sung to them, as it worked, "I've got your job, I've got your job." The machine was one of the most remarkable shoe machines ever built. Some of its motions were exactly like those of the hand lasters. So Matzeliger's machine proved vain the boast of the laster that a machine could not be built to last shoes. The story of Matzeliger well illustrates how intricate are some of the workings of our complex civilization. Matzeliger came to this country, from distant Dutch Guiana, unused to our ways. Yet he built a machine that revolutionized the lasting of shoes, substituting a machine for the hand methods that had been employed since the days of the first American shoemakers. The lasting machine, like the McKay sewing machine, has improved product, decreased cost and decreased hours of labor and has multiplied production. The hand laster considered it a good day's work to last 60 pairs of shoes in the old fashioned way. An operator of a lasting machine today will do from 200 to 300 pairs of shoes daily, according to the nature of his work, and some operators have lasted as many as 700 pairs in ten hours. The invention of Matzeliger was

37

greatly improved by Sherman Ladd. Of Mr. Ladd, it has been said that he "couldn't invent a tooth-pick, but there never has been a machine which he couldn't improve upon." Sidney W. Winslow and George W. Brown made the invention of Matzeliger a commercial success. Mr. Winslow began his career as an employe in his father's shoe factory in Salem, Mass. George W. Brown worked in a general store in Vermont in the days of his youth, was in the employ of some Western railroads, and then became interested in the sewing machine business. Mr. Brown and Mr. Winslow made their company the Consolidated Lasting Machine Co., the strongest shoe machinery company in the world. Eventually, they formed the United Shoe Machinery Co. by consolidating important machinery companies with the Consolidated Co.

38

PART X

Methods of making shoes have been revolutionized by American shoemakers in the past 275 years. Changes have been made slowly. One generation improving upon the methods of its predecessors, until the sum total of the changes was a revolution of the industry from a manual to a mechanic industry. Shoes of colonial days were commonly sewed by hand. Heavy shoes were welt sewed, and light shoes were turn made. Some heavy boots were copper nailed. One of the first improvements in making shoes came from the use of the shoe peg. The historical sketch of the shoe industry, published in the U. S. census reports for 1900 is authority for the statement that the shoe peg was invented in 1815. The first pegs were whittled out by hand. The pegs, when properly driven, firmly fastened the sole to the uppers. The first machine in the shoe industry appears to have been a shoe pegging machine. It was invented by Samuel Preston, a Danvers, Mass., shoe manufacturer, in 1833. A pair of shoes pegged on it is preserved in the Essex Institute, in Salem. The pegging machine, however.

39

did not come into successful use until about 1859, when a machine invented in 1851, by A. C. Gallahue, was perfected. This machine really began the revolution of the shoe industry, from a manual to a mechanical industry. The McKay machine, which came soon after it, is given the credit of revolutionizing the industry. The first machine in successful practical use in the shoe industry was the rolling machine. It is a simple machine, consisting of two iron rollers. A shoemaker passed a pair of soles through the rollers and so compressed the leather. By using the rolling machine, the shoemaker saved himself half an hour labor of pounding a pair of soles on a lap stone with a flat face hammer. The McKay machine and the pegging machine were rapidly adopted by shoe manufacturers. But they did not put an end to the occupation of hand shoemaking. The McKay shoes and the pegged shoes, too, were stiff. Their soles were like a board. People were accustomed to the flexible hand sewed shoes, and those persons who could afford it continued to buy hand sewed shoes made by custom shoemakers. In 1862 August Destroy secured patents on a welt sewing machine. He assigned his patents to James Hanan, of Hanan & Son, shoe manufacturers, of Brooklyn. Mr. Hanan interested Charles Goodyear, an expert machinist, in the machine. Mr. Goodyear developed it,

40

and the machine took his name, even as the invention of Blake took the name of McKay. The welt sewing machine did not come into use until about 1876, however. From that time the industry of making shoes by hand began to wane rapidly. The machine accurately imitated hand methods of making shoes and sewed soles to uppers with stitches almost as fine as could the skilled hand shoemakers. There have been invented, developed and brought into use in the shoe industry a thousand and one machines besides these important and successful ones. All of them have contributed in a greater or less extent to the saving of time and increasing the wages of the shoemaker and to the improvement of product and decrease of price of product. These many machines, however, would have been of small value had they not been harnessed to the giant powers, steam and electricity. The first machines; were driven by hand power or foot power. Some enterprising shoe manufacturer adopted the horse mill that was in common use in the textile factories. In about 1855 the steam engine was substituted for the horse mill and along in 1890, the electric motor began to take the place of the, steam engine. William F. Trowbridge, an enterprising shoe manufacturer of Feltonville, now Trowbridge, Mass., employed three stout Irishmen

41

to turn over the main power wheel in his factory. Later, he employed his horse, ''Old General." In 1855, Mr. Trowbridge had a steam engine set up in his factory. It was the first used in the shoemaking industry. One man performed the entire process of making shoes in colonial times. He did all his work with his own hands. Today, in some shops, a single shoe passes through the hands of 100 employees, 90 of whom operate machines. A colonial shoemaker spent a day, more or less making a pair of shoes. In one modem factory, a pair of fine shoes has been made in 15 minutes. There are few men today who can make a shoe, performing the entire operation. But there are some men who have built up organized establishments that will make twenty thousand pairs of shoes in a day.

42

PART XI

American tanners make the best leather in the world. The superior quality of their product helps American shoemakers to make the best of shoes. The American leather manufacturing industry has been built up slowly from small beginnings, as has the American shoe manufacturing industry. The first leather was brought here from England. The colonists often used deer skins, tanned by the Indians. Many a colonist was his own tanner. Francis Ingalls, a tanner of Lincolnshire, England, settled in Lynn in 1629. Philemon Dickerson, a tanner, and servant of Benjamin Cooper of Branton, England passed his examination to come to this country May 10, 1637. He settled in Salem, and, in 1639, he was granted land on which to make tan pits and to dress hides and goat skins. The tanning industry was carried on by the Dutch in New York, the Quakers in Pennsylvania and the Cavaliers in the South. In 1800, William Rose, a tanner near Blackfriar's Bridge, London, came to Lynn. He was induced to come here by Ebenezer Breed, the same man who had

43

secured from Congress the passage of the law which put a protective tariff on American shoes. Rose practiced the art of making morocco leather, an art which the English had learned from the Spaniards and the Spaniards from the Moors. Rose was called ''the father of the American morocco manufacturing industry." He was a good tanner but was unfortunate in being intemperate in speech, act and appetite. He threw a tax collector into a river who demanded payment of a bill of him one day. Shortly before the Civil War, machinery was introduced into the leather making industry. At first the hand workmen thought it impossible to use machinery in making leather. But one by one the various labor saving machines were introduced and perfected, until today machinery is used in place of hand labor in all branches of leather making. Of course, the machinery has saved time, money and labor. In 1884, a tanner asked August Schultz if he couldn't make leather that would resist the action of perspiration of the feet better than did the then common alum tanned kid leather. Schultz was at the time a chemist for a New York City house. He was using chrome mordant in the process of dyeing wool. He substituted chrome for alum in tanning skins. But practical tanners laughed at his leather. It was stiff and hard.

44

and robin's egg in color. However, Robert Foederer, a morocco manufacturer of Philadelphia, had faith in the process. He began to experiment with it. After spending a great deal of time and money, he learned to fat liquor his chrome tanned leather. He dressed it with an emulsion of soap and oil, while it was drying. The chrome made a leather impervious to water, that resisted the action of perspiration from the feet, and the fat liquor made it soft and pliable. Foederer called his leather Vici kid, taking his trade mark from Caesar's famous message. Shoe manufacturers pronounced this chrome tanned leather the best made. Consequently, rival tanners undertook to make leather by the chrome process. The owners of the Schultz patents brought suits against many tanners for infringement on their patent. After costly suits, it was learned that Prof. Knapp, a German chemist, had used the chrome process for tanning leather in 1850. The suits were compromised. The chrome process has come into general use for the manufacturers of all kinds of leather. It has given American tanners leadership in the leather making industry. American tanners now tan about 20.000.000 hides and 100.000.000 skins annually. Their raw material, including their tanning agents, costs them about $ 200.000.000 annually.

45

They import more than $50.000.000 worth of skins annually, fetching them from the interior of Africa, the hills of India and from China, Siberia, Australia and South American countries. American tanners now make about $300.000.000 worth of leather annually, most of which is used for boots and shoes. A few million dollars' worth is used for upholstering automobiles and furniture, for binding books, for belting on machinery, for trunks, bags and valises, card cases and pocket books and for novelties.

46

PART XII

The organization of the modern factory system makes an interesting chapter of the story of the shoe industry. It shows how individual enterprise has given place to co-operative effort, how the jack of all trades has become a specialist, and how habits and opinions of men have changed as new and better conditions have been created. An early shoemaker labored alone, upon his own responsibility. He bought his leather himself, made shoes completely, and sold his product to his customer personally. He was a unit in an individual system of production. The shoemaker of today is a unit in a collective system. After the Revolution, the "bag boss" appeared. He made shoes in his own little shop, packed them into a bag, threw the bag over his shoulder and tramped from house to house, and from town to town, selling shoes from door to door. Some of the bag bosses walked to Boston, or other large cities and sold their shoes to wholesalers and retailers. Ambitious shoemakers employed other shoemakers to work for them. They became manufacturers or employers. The shoemakers, whom they employed, became employees. This was the beginning of the di-

47

vision between capital and labor, in the shoe trade. Some shrewd shoemakers observed that one man could perform some part of shoemaking better than another. For instance, one man excelled in cutting and fitting boot tops, while another excelled in sewing on soles and finishing them. So teams of workers were formed. One man gave all his time to cutting and fitting uppers and the other to sewing on soles and finishing them. Teams of turn workers were also formed. The manufacturers made a specialty of buying material for their employees to make up into shoes and of selling the product of their employees. As they prospered, they hired more shoemakers. A few manufacturers built factories to accommodate their workmen. Other manufacturers built factories which were practically store houses for raw material and finished product. Shoemakers took home material for a week's work from the factory, and to make the shoes in the little shop at home. Along in 1850, manufacturers began to equip their factories with machinery, and to drive the machinery by steam power. They called shoemakers from their little shops at home to the shoe factories of the shoe centers to operate the machines. Then it became necessary to organize the shoemakers into shop crews, and to establish factory discipline. This was a huge task. The typical shoemaker had long been his own

48

boss. He worked in his little shop at home when, and how, he pleased. He looked upon the factory rules, which required him to work from 7 o'clock in the morning to 6 at night as prison rules, and he considered the shriek of the factory whistle an order of a stern Czar whom he must obey. He believed obedience to the orders of the foreman a surrender of his personal rights and liberties, and he was certain that machinery would, labor saving machinery, deprive him of his occupation and reduce him to slavery and poverty. Indeed, it was a common practice for the old fashioned shoemakers to resist the factory system, and they aso fought against labor saving machinery by striking against its introduction, or, by attempting the crafty trick of causing the machine to do work much poorer than could be done by hand. One machine followed another until practically every part of the process of making shoes has become a mechanical work, and not manual. As the machines appeared, shoemakers undertook to operate them. Each shoemaker undertook to run one machine only. So the specialist in the shoemaking, the man who operates one machine alone, has taken the place of the man who performed by hand the entire process of making a shoe. Yet each specialist has to work in harmony with his neighbor so that the factory system may run smoothly. The assembling of shoemakers into factories called for men to organize and train them, just as the

49

assembling of a group of men in an army for warfare, in the early state of society, called for leaders to form and drill them. Superintendents and foremen, or overseers of departments, appeared in the factories. There is today one foreman, or superintendent to each group of 50 shoemakers for the entire shoe industry. Some of the large shoe firms employ 100 superintendents and foremen in their factories. The business, as well as the labor, of manufacturing shoes, has been sub-divided, and each division has come into the charge of a specialist. The large shoe manufacturing firms of today have one man who is a specialist in leather buying, another one who is a specialist in securing lasts and patterns, another man in charge of buying miscellaneous supplies, a manager of the sales department, an executive officer sometimes called a manager of the factory, or superintendent, still another man in charge of the finance, advertising, statistics, and even of the foreign sales department. The little factories in which one man labored, a ruler of all that he surveyed; have grown into large establishments, in which are employed a thousand and more men daily, and in which are made shoes to the quantity of 10.000 pairs daily, and even more. The large shoe manufacturing companies of the country today operate groups of factories and make 25.000 pairs of shoes daily and even more. The annual daily product of some of the big factories exceeds the entire

50

product of all the shoemakers in the country in colonial times. The introduction and use of shoe machinery, and the development of the factory system, led to increase in wages, shortening of hours of labor, and improvement of product. Wages rose from the $ 5 and $ 6 level of the days of hand shoemaking to $ 8, $ 10, $ 12 and $ 15 a week, and even higher, for some shoemakers of today earn $ 1.000 a year in wages. Hours of labor have been shortened from twelve to ten, and from ten to nine, and now shoemakers are seeking the eight hour day and in a few cases they have gained it. Increased wages and shortening of hours have, of course, enabled shoemakers to adopt and enjoy higher standards of living than did their predecessors.

51

PART XIII

Further organization of the boot and shoe industry has resulted in the building up of large corporations, the forming of strong associations of manufacturers and shoemakers, and the centralizing of the industry in certain communities. Some large shoe firms have a capital of $ 1.000.000 and more and manufacture and distribute $ 10.000.000 worth and more shoes annually. One manufacturing firm has 700 retail agencies for the distribution of its shoes in this country, and another has circled the world with a chain of shoe stores. New England, the birthplace of the shoe industry, is still the dominating factor in the shoe manufacturing business of the nation. It makes more than half of the shoes that are produced in this country each year. It sends its shoes to all parts of this country, and to every foreign country in which white men have settled. It is a leader in the building up of America's foreign trade of more than $ 10.000.000 annually. Boston is the great shoe and leather market of the world. It is the central point for shoe buyers as well as those who have shoes to sell. Every live and progressive buyer of shoes in the country visits Boston market twice a year,

52

once in January and again in July, when samples of new shoes for coming seasons are shown. Some buyers visit Boston once a month. The New England Shoe & Leather association is the largest organization in the world devoted to the advancement of the welfare of the shoe and leather and allied trades. Its membership is made up of a large number of manufacturers of New England. It represents their crystallized sentiment. The Boston Boot & Shoe club is the leading social organization of men of the shoe trade. In Boston fashion, it dines monthly and listens to speeches by distinguished men, who discuss topics of close interest to the shoe trade. It promotes the social graces, and brings into pleasant companionship men who may be rivals in business, or even strangers to each other, though engaged in the same lines of business. There is also a large and influential organization of shoe makers, the Boot & Shoe Workers' Union. John F. Tobin is its president and it has a membership of 30.000. It regulates conditions of employment of shoemakers. It makes contracts with manufacturers fixing the hours of labor and the wages to be paid, and providing for the arbitration of any disputes that may arise between manufacturers and its members. There are several other organizations of shoe makers, and, also, some small but excellent associations of superintendents and foremen.

53

A new movement is being organized. Its purpose is to build up a Greater New England. Its leaders are Charles C. Hoyt, President of the New England Shoe & Leather association, Alfred W. Donovan, President of the Boston Boot & Shoe club, and Thomas F. .Anderson, who is Secretary of both organizations. There has rallied to the advancement of this movement the leading organizations of the shoe and leather trade in Boston and in nearby cities, and, also, a large number of men of the shoe, leather and allied trades. These, Greater New Englanders believe in the maintenance and advancement of New England's traditional supremacy in shoe manufacturing in the past and in the development of New England character in shoe making in the future, so that shoes "Made in New England" shall be known as the best in the world, and shall be bought as the best by the entire world. It is a huge task to carry on this Greater New England movement. It will introduce, if it is carried out, a new era in the bhoe manufacturing industry. It promises to lead to a volume of business now undreamed of, and not methods and machinery and to relations between employers and employees, and to a general advancement of the industry to a plane as elevated above the plane of the industry today, as the plane of the industry of today is above that of the periods told about in this history.

54

PART XIV

The modern development of shoe machinery is along new lines, and it is not yet entirely clear to what future it will lead. In 1899, progress in modern business organization, as well as in shoe machinery, led to the establishment of the United Shoe Machinery Co., a corporation made up by the consolidation of the several important shoe machinery companies, the Goodyear Sewing Machine Co., the McKay Shoe Machine Co., and the Consolidated Lasting Machine Co. and their auxiliary companies. These concerns had possession of the important machines used in the manufacture of shoes, and the organization of the United Shoe Machinery Co. brought them together in a system. The development of this system has brought up some new conditions. Relations between the machinery company and shoe manufacturers are unique. Similar relations are found in no other industry, neither at the present time nor in familiar history. So these new conditions and relations, must be considered from the view point of the twentieth century that seeks what is best for the world, not from the viewpoint of the past that says this was best and looks upon that best as a standard for all time.

55

At first, shoe manufacturers resented the new system of shoe machinery, and found much fault with it. But, now, a great number of shoe manufacturers regard the United Shoe Machinery Co. as a partner in their business, and have come to believe that there is established, not a corporation control of the shoe machinery business, but a new form of co-operation in business. Whatever the new state of affairs may be, it is certainly contributing much to the welfare of all concerned, to the general public as well as to manufacturers of shoes, and the shoe machinery company. Methods employed under the new system of handling shoe machinery are new. The U. S. M. Co. equips shoe factories, in this country and abroad, dealing with the smallest shops that employ only ten or twelve as well as the biggest concerns that employ thousands of persons and that make from 10,000 to 30,000 pairs of shoes, and even more, daily. All manufacturers, large or small, are dealt with upon the same terms, and with the same courtesy. There is no special rate for big fellows, nor any neglect of small fellows. The rebating idea is unknown to the shoe machinery industry. So the new system of handling shoe machinery provides for fair play. The United Shoe Machinery Company provides shqe manufacturers with "everything from a tack to a whole factory equipment". Not only does it provide anything of a mechanical nature, which may be used in shoe manufacturing, but it also teaches manufacturers,

56

or their employees, how to get the best possible results from the things which they use. It has a large corps of experts who go among the factories keeping machines in repair, and making suggestions to operators for the improvement of their product. Thereby, improvement in workmanship and in product is encouraged, and the shoemakers, as well as the shoe manufacturers, are benefitted, and the people get better shoes. So here is a practical education as a feature of the new system. Machinery set up in shoe factories by the Company is not sold outright, but is leased, on the royalty system. The manufacturer pays so much per pair for the use of the machine in making shoes. Because of this arrangement, the manufacturer does not have to tie up his capital in machinery, but keeps it actively employed in his manufacturing business. He pays for his machinery only as he uses it. As the income of the Company depends upon the number of shoes made upon its machines, it is the plain duty of the Company to keep its machines m the best possible condition, and to have the best shoes made on them that can be produced. This new feature of the new system of handling machinery makes the Company something like a public service corporation. The royalty system for the use of new shoe machinery corresponds in certain respects to the railroad system. The railroad companies provide the cars, and people pay for

57

the use of them as they ride upon them. A person who wishes to make a journey does not have to build or buy a railroad line and equip it. He merely pays for the use of such facilities as the railroad company provides. Likewise, a shoe manufacturer does not have to build or buy shoe machinery. He merely pays for machinery as he uses it. The new systems of doing business have at times been vigorously attacked. This is natural, for it is not yet clear in the public mind where injurious competition leaves off and where beneficial co-operation begins. But it is apparent that the new system of handling shoe machinery has led to a great amount of good. It appears a new form of cooperation which benefits all persons who come into contact with it. As to the benefits that have come from the new system of handling machinery, it may be stated that the records show that the United Shoe Machinery Company has paid good returns to investors, thereby profiting and encouraging capital, and that it has increased the wages of its employees and shortened the hours of labor, thereby profiting and encouraging labor. It has benefitted the shoe trade, and, also, the public, for shoe manufacturers are making more shoes and better shoes, and consequently they have a larger business and the people have more shoes and better shoes. From 1890 (the year after the organization of the U. S. M. Co.) to 1900, the product of American shoe manufacturers increased from $ 220.000.000 to $ 258.000.000,

58

a gain of 17 per cent, and from 1900 to 1905, it increased from $ 258.000.000 to $ 320.000.000, a gain of 23 per cent. Statistics show that people have more shoes and better shoes today than ever before. This feature of improvement in the shoe business is discussed in other chapters. Furthermore, the development of shoe machinery has enabled American shoe manufacturers to gain the foremost position among the nations of the world in the exporting of shoes. During ten years, the exports of American shoes has increased from $1.000.000 to $ 11.000.000. Superiority of American machinery has undoubtedly contributed in a large measure to the growth of the export trade. The true worth of an industrial corporation, as well as of a man, is tested in its own home. The United Shoe Machinery Company is held in high esteem in Beverly, the city in which its factory is located, and in which its president, Sidney W. Winslow, makes his home. It is his native place. The company is considered a public benefactor, not alone because it employs 5,000 men, and pays them good wages (the average wages in Beverly are the highest in the state of Massachusetts) but because it is developing twentieth century ideals in industry. Its buildings are of concrete, that wont burn down. So insurance costs, an economic waste, are saved. The buildings have the best heating, lighting, ventilating and sanitary equipment, so the health of employees is safe-guarded.

59

A big restaurant provides employees with good dinners at cost. It is based on the theory that the man who eats well works well. About the factories are lawns and gardens, they being maintained on the theory that the man who looks out upon a pleasant view cheers up, and does better work than the man who might look out upon rough or unpleasant things, such as a factory dump. A factory farm provides fresh vegetables for the factory restaurant, and, also, provides opportunity for employees to raise vegetables for their own homes, or to secure shrubs and flowers for their homes. The employees have organized the United Shoe Machinery Athletic club. It has a gun club, baseball, soccer football, motor boat and tennis divisions. To encourage out of door sports the Company has given a large athletic field, and a substantial club house, with locker rooms, baths, bowling alleys, billiard room, reading room, and a large hall for dances, entertainments and other gatherings. The gift of the club house was made with the recommendation that employees play hard and earnestly, and enjoy well their leisure, for men who do so get the best results in the shop, the home, and wherever else life takes them. The employees have an association that pays benefits in case of sickness, accident or death. Many employees have taken policies from the insurance department of Massachusetts savings banks. So, here in this Beverly factory,

60

there is actively going on the work of building up a newer and higher civilization for this twentieth century. Wages have been increased and hours of labor shortened, and men have been in many ways encouraged to excel in their work, and to create new and better ways of doing work. The health of the body and mind is protected, and men are encouraged to preserve and increase their physical strength through games of the athletic field and club house, and to increase the capacity of their minds by study of machinery, in the school, or in the inventive department. These things tend to make the upbuilding of a higher civilization, and to the wiping out of those great evils of poverty and sickness, from which the world has suffered so long that it thinks them necessary evils. Furthermore these, and the protection of the benefit association and of the savings bank insurance, ward off the want and despair that often comes among families of workmen when sickness, or death, or old age, overtakes the bread winner. These conditions seem to show that the new system of handling machinery which is practised by the U. S. M. Co. is one of the practical methods of co-operation that is well worked out, and that is adding to the real prosperity of the people who come into contact with it.

61

PART XV

It was a century ago, a common practice to ''send out" shoes to be made up. Manufacturers had factories in the large towns, or shoe centres. These factories were really warehouses. In them, the manufacturer kept his raw material and his finished shoes. Each week, he distributed "stock" or leather and supplies, to his shoemakers, and he received from them the shoes which they had made during the week, in their little shops at home. Shoemakers who lived near the factories came to them, wheeling their shoes in a barrow, or fetching them in a bag, or basket. Some sent express wagons on regular weekly trips among shoemakers who lived distant from the factory, even to New Hampshire towns. The "shoe freighters," as they were called, took a week for making a round trip between New Hampshire towns and Lynn. Enterprising shoemakers continued to do business individually, even after the factory system was introduced. One young man, Putnam by name, was told by his employer, a Danvers shoe manufacturer, that there was no work for him, because business was bad.

62