- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

Sewing Machines Systems

PRINCIPLES OF ACTION OF SEWING MACHINES

Lock Stitch

Definition. A stitch made by a sewing machine by firmly linking together two threads or stitches.

Lock Stitch Machines. When two threads are used on a machine, it is classified as a lock-stitch machine, again taking the name from the way in which the threads are interlinked in the material in the formation of the stitch. In this case, the work is done with one thread on the upper side of the material and one thread on the under side. The upper thread is carried thru the cloth by the needle and is then passed around the bobbin thread. The threads are tightened, thus locking the two threads in the material in such a manner that they cannot be separated or unraveled without cutting or breaking (Fig. 1)

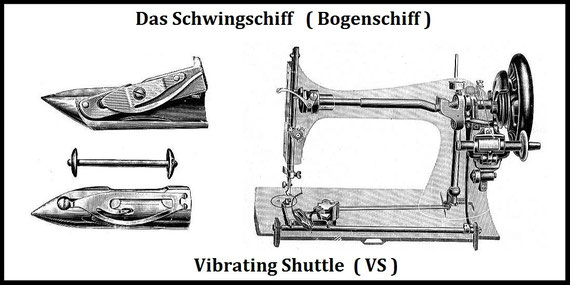

Before we describe the mechanism used in forming the lockstitch, we must divide this class further into parts since there are three methods by which the lock-stitch is formed and each method has its own distinct underlying characteristics or principles. We speak of these divisions as types, each type taking its name from the manner in which the mechanism works while forming the stitch. The three types are known as (a) the vibrating, (b) the rotating, (c) the oscillating.

Lock-Stitch by Shuttles

*Philip H. Diehl (January 29, 1847 – April 7, 1913) was a German American mechanical engineer and inventor who held several U.S. patents. Together with Lebbeus B. Miller, Diehl invented and patented the "oscillating shuttle" bobbin driver designed and a sewing machine build around it.

Oscillating shuttle machines mount their bobbin on the hook, and reciprocate the hook through a short arc. The design was popularized in Singer's models 15 'Improved Family' and 31.

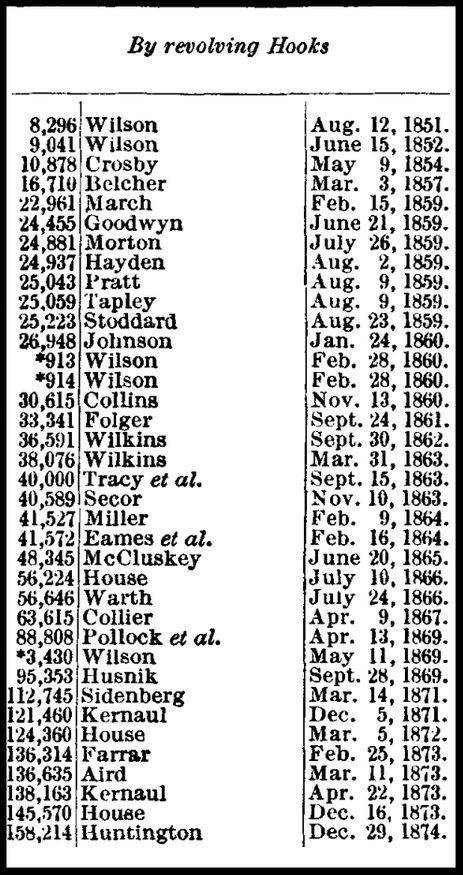

Lock-Stitch by Revolving Hooks

* The rotating looper a enters the loop of the needle-thread and carries it around a loose disk-bobbin b on the face of the hook.

(Wheeler & Wilson) rotating hook

Rotary vs. Oscillating Hook

Sewing Machines

Whether your shopping for a new sewing machine or just looking to better understand the one you have, it can be helpful to understand the differences in features and functionality between machines. One feature that plays a key role in how your sewing machine works is the hook system. This is the part of the machine that catches the thread as it is forced out of the needle to create a stitch. There are two main types of hooks, rotary and oscillating. Both hooks create lockstitch stitches, but they work differently and have a couple different considerations. Let’s take a closer look at these two systems.

Rotary Hook Machines

A rotary hook machine, sometimes called a full rotary machine, is a machine in which the hook rotates in a full circle around a stationary bobbin. In this system, the shuttle hook catches the thread when the needle is going back up through the fabric and the hook then carries the thread around the bobbin cage to form the stitch, going all the way around the bobbin.

Rotary machines use a gear or timing belt linkage between the top and bottom shafts of the machine. To keep this function working properly, it must be set very precisely. This need for precision means that rotary hook sewing machines have tight thread tolerances. In other words, they work well with threads of specific, recommended sizes but can be unforgiving outside of their range. Additionally, small rotary hook machines tend to need their timing adjusted more frequently to maintain that precision.

A sewing machine with a rotary hook runs smoother at higher speeds (no vibrating), is quieter and has less frequent thread jams than machines with oscillating hooks. However, these machines are usually more expensive than oscillating hook machines. Rotary hooks are the standard choice for industrial sewing machines.

The Sailrite 111, the Sailrite Professional Series and the Sailrite Big-N-Tall are all full-sized, industrial machines with rotary hooks.

Oscillating Hook Machines

Oscillating hook sewing machines have a hook that, instead of rotating in a full circle, oscillates back and forth. In this system, the hook picks up the upper thread from the needle and carries it down around the bottom of the bobbin cage. Once it has done this, the hook reverses its direction and returns to its original location.

Oscillating hook sewing machines have simpler mechanics and tend to be more affordable than rotary hook machines. They are also easier to time and maintain. Since oscillating hook machines have looser tolerances than the precise rotary hooks, oscillating hook machines can sew heavier threads in smaller machines. The drawbacks to oscillating hook machines are that they are louder and are generally not as fast.

Both the Sailrite Ultrafeed LS-1 and LSZ-1 Sewing Machines have oscillating hooks.

Which Machine Do I Have?

If you’re looking at purchasing a new machine, the shuttle type is often listed in the machine’s specifications. If you’re unsure what type of hook your current machine has, there’s a simple way to tell. Remove the bobbin from your machine and turn the balance wheel by hand. Watch the motion of the hook. Does it make a full circle or does it change directions? If it changes direction, it’s an oscillating hook and if it stays on a full circular pattern it’s a rotary hook.

Conclusions

In general, oscillating hook machines offer more versatility with their looser thread tolerances. We find that they tend to be easier for amateurs to use because they are more forgiving to use and are easier to maintain because they require fewer adjustments. However, both types of machines will give you excellent stitches and performance. For many, the choice is preferential or driven by necessary features.

Keyword List

Reciprocating Shuttle

The shuttle is used to carry the bobbin, wound with thread, through the loop formed in the upper thread from the needle in order to form the lock-stitch. Reciprocating means it has a back & forth motion & this term is applied to a shuttle which moves toward & away from the operator in a straight line.

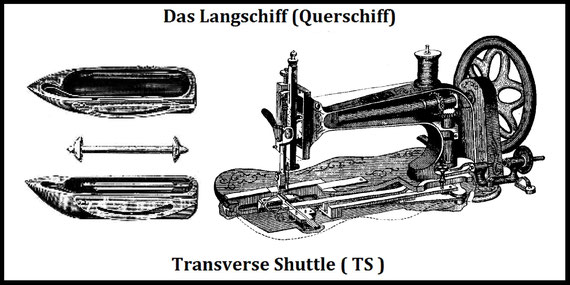

Transverse shuttle

The shuttle carry the bobbin in a boat-shaped shuttle and reciprocate the shuttle along a straight horizontal shaft.