The Invention

Of the Sewing Machine

Chapter Two

Elements of a Successful Machine

The requirements for producing a successful, practical sewing machine were a support for the cloth, a needle to carry the thread through the fabric and a combining device to form the stitch, a feeding mechanism to permit one stitch to follow another, tension controls to provide an even delivery of thread, and the related mechanism to insure the precise performance of each operation in its proper sequence. Weisenthal had added a point to the eye-end of the needle, Saint supported the fabric by placing it in a horizontal position with a needle entering vertically, Duncan successfully completed a chainstitch for embroidery purposes, Chapman used a needle with an eye at its point and did not pass it completely through the fabric, Krems stitched circular caps with an eye-pointed needle used with a hook to form a chainstitch, Thimonnier used the hooked needle to form a chainstitch on a fabric laid horizontally, and Hunt created a new stitch that was more readily adapted to sewing by machine than the hand stitches had been, but, although each may have had the germ of an idea, a successful machine had not evolved. There were to be hundreds of patents issued in an attempt to solve these and the numerous minor problems that would ensue. But the problems were solved. And, in spite of its Old World inception, the successful sewing machine can be credited as an American invention.

Although the invention of the practical sewing machine, like most important inventions, was a many-man project, historians generally give full credit to Elias Howe, Jr. Though such credit may be overly generous, Howe’s important role in this history cannot be denied.

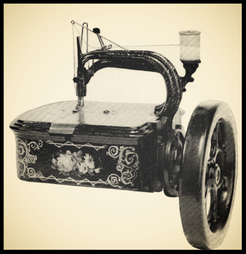

Elias Howe, Jr., was born on a farm near Spencer, Massachusetts, but he left home at an early age to learn the machinist’s trade.[33] After serving an apprenticeship in Lowell, he moved to Boston. In the late 1830s, while employed in the instrument shop of Ari Davis, Howe is reported to have overheard a discussion concerning the need for a machine that would sew. In 1843, when illness kept him from his job for days at a time, he remembered the conversation and the promises of the rich reward that reputedly awaited the successful inventor. Determined to invent such a machine, he finally managed to produce sufficient results to interest George Fisher in buying a one-half interest in his proposed invention. By April 1845, Howe’s machine (fig. 14) was used to sew all the seams of two woolen suits for men’s clothing. He continued to demonstrate his machine but found that interest was, at best, indifferent.

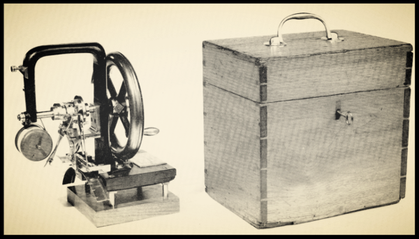

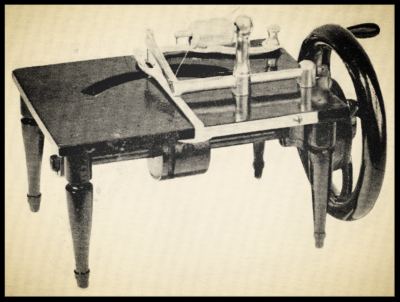

Nevertheless, Howe completed a second machine (fig. 15), which he submitted with his application for a patent. The fifth United States patent (No. 4.750) for a sewing machine was issued to him on September 10, 1846. The machine used a grooved and curved eye-pointed needle carried by a vibrating arm, with the needle supplied with thread from a spool. Loops of thread from the needle were locked by a thread carried by a shuttle, which was moved through the loop by means of reciprocating drivers. The cloth was suspended in a vertical position, impaled on pins projecting from a baster plate, which moved intermittently under the needle by means of a toothed wheel. The length of each stitching operation depended upon the length of the baster plate, and the seams were necessarily straight. When the end of the baster plate reached the position of the needle, the machine was stopped. The cloth was removed from the baster plate, which was moved back to its original position. The cloth was moved forward on the pins, and the seam continued.

In his patent specifications, Howe claimed the following:

1. The forming of the seam by carrying a thread through the cloth by means of a curved needle on the end of a vibrating arm, and the passing of a shuttle furnished with its bobbin, in the manner set forth, between the needle and the thread which it carried, under combination and arrangement of parts substantially the same with that described.

2. The lifting of the thread that passes through the needle-eye by means of the lifting-rod, for the purpose of forming a loop of loose thread that is to be subsequently drawn in by the passage of the shuttle, as herein fully described, said lifting-rod being furnished with a lifting pin, and governed in its motion by the guide-pieces and other devices, arranged and operating substantially as described.

3. The holding of the thread that is given out by the shuttle, so as to prevent its unwinding from the shuttle-bobbin after the shuttle has passed through the loop, said thread being held by means of the lever or slipping-piece, as herein made known, or in any other manner that is substantially the same in its operation and result.

4. The manner of arranging and combining the small lever with the sliding box, in combination with the spring-piece, for the purpose of tightening the stitch as the needle is retracted.

5. The holding of the cloth to be sewed by the use of a baster-plate furnished with points for that purpose, and with holes enabling it to operate as a rack in the manner set forth, thereby carrying the cloth forward and dispensing altogether with the necessity of basting the parts together.

The five claims, which were allowed Howe in his patent, have been quoted to show that he did not claim the invention of the eye-pointed needle, for which he has so often been credited. The court judgment [34] that upheld Howe’s claim to his patented right to control the use of the eye-pointed needle in combination with a shuttle to form a lockstitch was mistakenly interpreted by some as verifying control of the eye-pointed needle itself.

Fig. 15 — Howe’s patent model, 1846.

After patenting his invention, Howe spent three discouraging years in both the United States and in England trying to interest manufacturers in building his sewing machine, under license. Finally, for £250 sterling, he sold the British patent rights to William Thomas and further agreed to adapt the machine to Thomas’ manufacture of umbrellas and corsets. [35] This did not prove to be a financial success for Howe and by 1849 he was back in the United States, once again without funds.

On his return, Howe was surprised to find that other inventors were engaged in the sewing-machine problem and that sewing machines were being manufactured for sale. The sixth United States sewing-machine patent (No. 5.942) had been issued to John A. Bradshaw on November 28, 1848, for a machine specifically stated as correcting the defects in the E. Howe patent. Bradshaw did not purport that his machine was a new invention. His specifications read:

The curved needle used in Howe’s machine will not by itself form the loop in the thread, which is necessary for the flying bobbin, with its case, to pass through, and has, therefore, to be aided in that operation by a lifting-pin, with the necessary mechanism to operate it. This is a very bungling device, and is a great incumbrance to the action of the machine, being an impediment in the way of introducing the cloth to be sewed, difficult to keep properly adjusted, and very frequently gets entangled between the thread and the needle, by which the latter is frequently broken. This accident happens very often, not withstanding all the precaution which it is possible for the most careful operator to exercise; and inasmuch as the delay occasioned thereby is very considerable, and the needles costly and difficult to replace, it is therefore very important that their breaking in this manner be prevented, which in my machine is done in the most effectual manner by dispensing with the lifting-pin altogether, the loop for the flying bobbin to pass through being made with certainty and of the proper form by means of my angular needle moved in a particular manner just before the flying-bobbin case is thrown. The shuttle and its bobbin for giving off the thread in Howe’s machine are very defective ... my neat and simple bobbin-case ... gives off its thread with certainty and uniformity.... The baster-plate in the Howe machine is very inconvenient and troublesome ... in my machine ... the clamp ... is a very simple and efficient device.... The Howe machine is stationary, and the baster-plate or cloth-holder progressive. The Bradshaw machine is progressive and the cloth-holder stationary.

Bradshaw’s patent accurately described some of the defects of the Howe machine, but other inventors were later to offer better solutions to the problems.

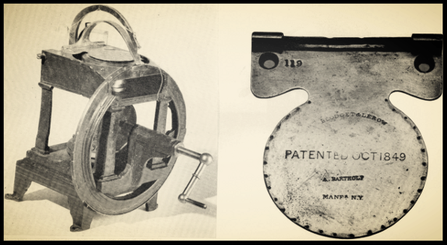

Fig. 17 — Morey and Johnson sewing machine, 1849. Below: The machine is marked with the name of its maker, Safford & Williams. The number 49 is a serial number. Missing parts have been replaced with plastic.

Although the Bradshaw machine was not in current manufacture, a machine based on it received the seventh United States sewing-machine patent. Patent 6,099 was issued to Charles Morey and Joseph B. Johnson on February 6, 1849. Their machine (fig. 17) was being offered for sale even before the patent was issued.

This was the first American patent for a chainstitch machine. The stitch was made by an eye-pointed needle carrying the thread through the fabric; the thread was detained by a hook until the loop was enchained by the succeeding one. The fabric was held vertically by a baster plate in a manner similar to the Howe machine. Although not claimed in the patent description, the Morey and Johnson machine also had a bar device for stripping the cloth from the needle. This bar had a slight motion causing a yielding pressure to be exerted on the cloth. Although the patent was not granted until February 6, 1849, the application had been filed in April of the previous year. The machine was featured in theScientific American on January 27, 1849 (fig. 18):

Morey and Johnson Machine—These machines are very accurately adjusted in all their parts to work in harmony, without this they would be of no use. But they are now used in most of the Print Works and Bleach Works in New England, and especially by the East Boston Flour Company. It sews about one yard per minute, and we consider it superior to the London Sewing Machine the specification of which is in our possession. It [Morey and Johnson] is more simple—and this is a great deal.... The price of a machine and right to use $135. [36]

An improvement in the Morey and Johnson machine was patented by Jotham S. Conant for which he was issued a patent on May 8, 1849. Conant’s machine offered a slight modification of the cloth bar and of the method of keeping the cloth taut during the stitching operation. No successful use of it is known.

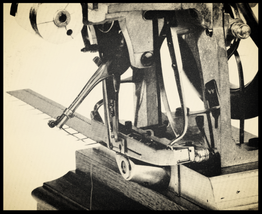

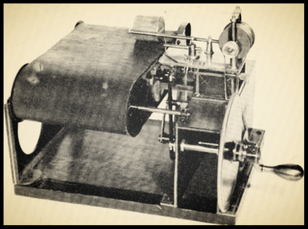

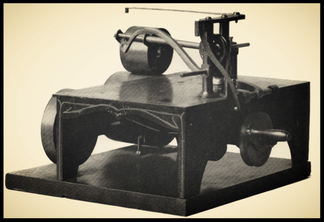

A second improvement of the Morey and Johnson patent was also issued on May 8, 1849; this United States patent (No. 6,439) was to John Bachelder for the first continuous, but intermittent, sewing mechanism. As shown in the patent model (fig. 19), his clothholder consisted of an endless belt supported by and running around three or any other suitable number of cylindrical rollers. A series of pointed wires projected from the surface of the belt near the edge immediately adjacent to the needle. The wires could be placed at regular or irregular distances as required. The shaft of one of the cylindrical rollers, which supported the endless clothholder, carried a ratchet wheel advanced by the action of a pawl connected to the end of the crankshaft by a small crankpin, whose position or distance from the axis of rotation of the shaft could be adjusted.

Fig. 18 — A Morey and Johnson sewing machine as illustrated in Scientific American, January 27, 1849.

By this adjustment the extent of the vertical travel of the impelling pawl was regulated to control the length of the stitch. A spring catch kept the ratchet wheel in place at the end of each forward rotation of the wheel by the pawl. A roller placed over the endless belt at its middle roller pressed the cloth onto the wire points. A curved piece of metal was bent over and down upon the top of the belt so that the cloth, as it was sewed, was carried toward and against the piece by the belt. The cloth rose upon and over the piece and was separated from the points. When the machine was in motion the cloth was carried forward, passed under the needle, was stitched, and finally, passed the separator and off the belt. A vertically reciprocating, straight, eye-pointed needle, a horizontal supporting surface, and a yielding cloth presser were all used, but none were claimed as part of the patent. These were later specifically claimed in reissues of this patent.

Bachelder’s one specific claim, the endless feed belt, was not limited to belt feeding only. As he explained in the patent, a revolving table or a cylinder might be substituted.

Fig. 19 — Bachelder’s patent 6,439 May 8, 1849

Bachelder did not manufacture machines, but his patent was sold in the mid-1850s to I. M. Singer. [37] It eventually became one of the most important patents to be contributed to the “Sewing-Machine Combination,”a patent pool, which is discussed in more detail on pages 41 and 42.

While new ideas and inventors continued to provide the answers to some of the sewing-machine problems, Elias Howe began a series of patent suits to sustain the rights that he felt were his. Since his interest had never been in constructing machines for sale, it was absolutely essential for Howe to protect his royalty rights in order to realize any return from his patent. He was reported [38] to have supervised the construction of 14 sewing machines at a shop [39] on Gold Street in New York toward the close of 1850. Sworn contemporary testimony indicates that the machines were of no practical use. [40] Elias stated, in his application for his patent extension, [41] that he made only one machine in 1850-51. In 1852 he advertised [42] territorial rights and machines, but apparently did not realize any financial success until he sold a half interest in his patent to George Bliss in November 1852. [43] Bliss later began manufacturing machines that he initially sold as “Howe’s Patent”; however, these machines were substantially different from the basic Howe machine.

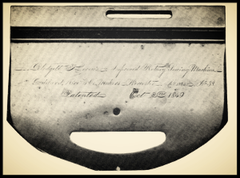

Fig. 20 — Blodgett & Lerow sewing machine, 1850, as manufactured by A. Bartholf, New York; the serial number of the machine is 19. At right, an original brass plate from the same type of machine with needle arm and presser foot and arm, serial number 119; the plate, however, does not fit the machine correctly.

On May 18, 1853, Elias Howe granted his first royalty license to Wheeler, Wilson & Company. Within a few months licenses were also granted to Grover & Baker; A. Bartholf; Nichols & Bliss; J. A. Lerow; Woolridge, Keene, and Moore; and A. B. Howe, the brother of Elias. These licenses granted the manufacturer the right to use any part of the Howe patent, [44] but it did not mean that the machines were Elias Howe machines. When a royalty license was paid, the patent date and sometimes the name was stamped onto the machine. For this reason, these machines are sometimes mistakenly thought to be Elias Howe machines. They are not.

Howe was also prevented from manufacturing a practical machine unless he paid a royalty to other inventors. Three of the major manufacturers and Howe resolved their differences by forming the “Sewing Machine Combination.” Although Howe did not enter the manufacturing competition for many years, he profited substantially from the royalty terms of the combination. In 1860, he applied for and received a seven-year extension on his patent.

Fig. 21 — Blodgett & Lerow sewing machine, 1850, stamped with the legend “Goddard, Rice & Co., Makers, Worcester, Mass.”and the serial number 37. Below: An original brass plate marked “No. 38”; this plate fits the machine perfectly.

There were Howe family machines for sale during this period, but these were the ones that Amasa Howe had been manufacturing since 1853. The machine was an excellent one and received the highest medal for sewing machines, together with many flattering testimonials, at the London International Exhibition in 1862. After the publication of this award the demand for (Amasa) Howe sewing machines was greatly increased at home and abroad. Elias took this opportunity to gain entry into the manufacturing business by persuading Amasa to let him build a factory at Bridgeport, Connecticut, and manufacture the (Amasa) Howe machines. Two years passed before the factory was completed, and Amasa’s agents were discouraged. The loss could have been regained, but the machines produced at Bridgeport were not of the quality of the earlier machines. Amasa attempted to rebuild the Bridgeport machines, but finally abandoned them and resumed manufacturing machines in New York under his own immediate supervision. [45] Elias formed his own company and continued to manufacture sewing machines. In 1867 he requested a second extension of his patent, but the request was refused. Elias Howe died in October of the same year.

Meanwhile, another important sewing machine of a different principle had also been patented in 1849. This was the machine of Sherburne C. Blodgett, a tailor by trade, who was supported financially by John A. Lerow. United States patent 6,766 was issued to both men on October 2, 1849. In the patent, the machine was termed as “our new ‘Rotary Sewing Machine’.” The shuttle movement was continuous, revolving in a circle, rather than reciprocating as in the earlier machines. Automatic tension was initiated, restraining the slack thread from interference with the point of the needle.

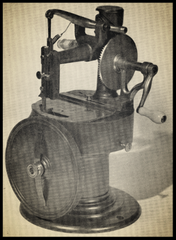

Fig. 22 —Wilson’s prepatent model for his reciprocating-shuttle machine, 1850.

The Blodgett and Lerow machine was built by several shops. One of the earliest was the shop of Orson C. Phelps on Harvard Place in Boston. Phelps took the Blodgett and Lerow machine to the sixth exhibition of the Massachusetts Charitable Mechanics Association in September 1850 and won a silver medal and this praise, “This machine performed admirably; it is an exceedingly ingenious and compact machine, able to perform tailor’s sewing beautifully and thoroughly.” [46] Although Phelps had won the earliest known premium for a sewing machine, and although the machine was produced commercially to a considerable extent (figs. 20 and 21), one outstanding flaw in its operation could not be overlooked. As the shuttle passed around the six-inch circular shuttle race, it put a twist in the thread (or took one out if the direction was reversed) at each revolution. This caused a constant breaking of the thread, a condition that could not be rectified without changing the principle of operation. Such required changes were later to lead I. M. Singer, another well-known name, into the work of improving this machine.

Also exhibited at the same 1850 mechanics fair was the machine of Allen B. Wilson. Wilson’s machine received only a bronze medal, but his inventive genius was to have a far greater effect on the development of the practical sewing machine than the work of Blodgett and Lerow. A. B. Wilson [47] was one of the ablest of the early inventors in the field of mechanical stitching, and probably the most original.

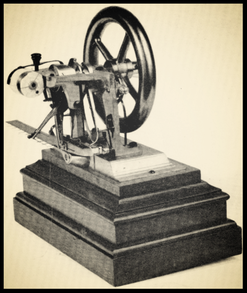

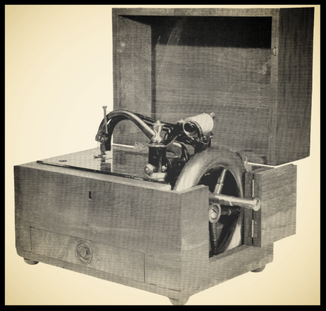

Wilson, a native of Willett, New York, was a young cabinetmaker at Adrian, Michigan, in 1847 when he first conceived of a machine that would sew. He was apparently unaware of parallel efforts by inventors in distant New England. After an illness, he moved to Pittsfield, Massachusetts, and pursued his idea in earnest. By November 1848 he had produced the basic drawings for a machine that would make a lockstitch. The needle, piercing the cloth, left a loop of thread below the seam. A shuttle carrying a second thread passed through the loop, and as the tension was adjusted a completed lockstitch was formed (fig. 22). Wilson’s shuttle was pointed on both ends to form a stitch on both its forward and backward motion, a decided improvement over the shuttles of Hunt and Howe, which formed stitches in only one direction. After each stitch the cloth was advanced for the next stitch by a sliding bar against which the cloth was held by a stationary presser. While the needle was still in the cloth and holding it, the sliding bar returned for a fresh grip on the cloth.

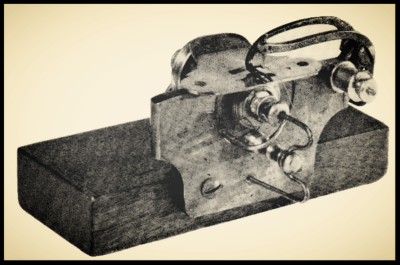

Wilson made a second machine, on the same principle, and applied for a patent. He was approached by the owners of the Bradshaw 1848 patent, who claimed control of the double-pointed shuttle. Although this claim was without justification, as can be seen by examining the Bradshaw patent specifications, Wilson did not have sufficient funds to fight the claim. In order to avoid a suit, he relinquished to A. P. Kline and Edward Lee, a one-half interest in his U.S. patent 7,776 which was issued on November 12, 1850 (fig. 23).

Fig. 23 — Wilson’s patent model, 1850.

Inventor Wilson had been associated with Kline and Lee (E. Lee & Co.) for only a few months, when, on November 25, 1850, he agreed to sell his remaining interest to his partners for $2,000. He retained only limited rights for New Jersey and for Massachusetts. The sale was fruitless for the inventor, as no payment was ever made. How much money E. E. Lee & Co. realized from the Wilson machine is difficult to determine, but they ran numerous ads in the 1851 and 1852 issues of Scientific American. A typical one reads:

A. B. Wilson’s Sewing Machine, justly allowed to be the cheapest and best now in use, patented November 12, 1850; can be seen on exhibition at 195 and 197 Broadway (formerly the Franklin House, Room 23, third floor) or to E. E. Lee & Co., Earle’s Hotel. Rights for territory or machines can be had by applying to George R. Chittenden, Agent. [48]

Another reads:

A. B. Wilson’s Sewing Machine ... the best and only practical sewing machine—not larger than a lady’s work box—for the trifling sum of $35. [49]

Fig. 24 — Wilson’s prepatent model for his rotary hook, 1851.

Fig. 25 —Wilson’s rotary-hook patent model, 1851.

Wilson severed relations with Lee and Kline in early 1851 shortly after meeting Nathaniel Wheeler, who was to become his partner in a happier, more profitable enterprise involving the sewing

machine.

Fig. 26 — Wilson’s stationary-bobbin patent model, 1852; a commercial machine was used since Wheeler, Wilson, Co. had begun manufacturing machines the previous year.

Wilson, with his two partners, was occupying a room in the old Sun Building at 128 Fulton Street, when Wheeler, on a business trip to New York City, learned of the Wilson sewing machine. Wheeler examined the machine, saw its possibilities, and at once contracted with E. Lee & Co. to make 500 of them. At the same time he engaged Wilson to go with him to Watertown, Connecticut, to perfect the machine and supervise its manufacture. Meanwhile, Wilson had been working on a substitute for the shuttle. He showed his model of the device, which became known as the rotary hook, to Wheeler who was so convinced of its superiority that he decided to develop this new machine and leave Wilson’s first machine to the others, who, by degrees, had become its owners.

Wilson now applied all his effort to improving the rotary hook, for which he received his second patent on August 12, 1851 (figs. 24 and 25). Wheeler, his two partners Warren and Woodruff, and Wilson now formed a new copartnership, Wheeler, Wilson and Company. They began the manufacture of the machines under the patent, which combined the rotary hook and a reciprocating bobbin. The rotary hook extended or opened more widely the loop of the needle thread, while a reciprocating bobbin carried its thread through the extended loop. To avoid litigation which the reciprocating bobbin might have caused, Wilson contrived his third outstanding invention, the stationary bobbin. This was a feature of the first machine produced by the new company in 1851, though the patent for the stationary bobbin was not issued until June 15, 1852 (fig. 26).

In all reciprocating-shuttle machines a certain loss of power is incurred in driving forward, stopping, and bringing back the shuttle at each stitch; also, the machines are rather noisy, owing to the striking of the driver against the shuttle at each stroke. These objections were removed by Wilson’s rotary hook and stationary bobbin. The locking of the needle thread with the bobbin thread was accomplished, not by driving a shuttle through the loop of the needle thread, but by passing that loop under the bobbin. The driving shaft carried the circular rotary hook, one of the sewing machine’s most beautiful contrivances. The success of the machine is indicated in an article that appeared in the June 1853 issue of Scientific American:

There are 300 of these machines now in operation in various parts of the country, and the work which they can perform cannot be surpassed.... The time must soon come when every private family that has much sewing to do, will have one of these neat and perfect machines; indeed many private families have them now.... The price of one all complete is $125; every machine is made under the eye of the inventor at the company’s machine shop, Watertown, Connecticut, so that every one is warranted ... agreement between Mr. Howe and Messrs. Wheeler, Wilson & Co., so every customer will be perfectly protected.... [50]

Fig. 27 — Wilson’s four-motion-feed patent model, 1854, is not known to be in existence; this is a commercial machine of the period. The plate is stamped “A. B. Wilson, Patented Aug. 12, 1851, Watertown, Conn., No. 1....”

This agreement was important to sales, as Elias Howe was known to have sued purchasers of machines, as well as rival inventors and companies.

The business was on a substantial basis by October 1853, and a stock company was formed under the name of Wheeler & Wilson Manufacturing Company. [51] A little more than a year later, on December 19, 1854, Wilson’s fourth important patent (U.S. patent 12,116), for the four-motion cloth feed, was issued to him (fig. 27). In this development, the flat-toothed surface in contact with the cloth moved forward carrying the cloth with it; then it dropped a little, so as not to touch the cloth; next it moved backward; then in the fourth motion it pushed up against the cloth and was ready to repeat the forward movements. This simple and effective feed method is still used today, with only minor modifications, in almost every sewing machine. This feed with the rotary hook and the stationary circular-disk bobbin, completed the essential features of Wilson’s machine. It was original and fundamentally different from all other machines of that time.

The resulting Wheeler and Wilson machine made a lockstitch by means of a curved eye-pointed needle carried by a vibrating arm projecting from a rock shaft connected by link and eccentric strap with an eccentric on the rotating hook shaft. This shaft had at its outer end the rotary hook, provided with a point adapted to enter the loop of needle thread. As the hook rotated, it passed into and drew down the loop of needle-thread, which was held by means of a loop check, while the point of the hook entered a new loop. When the first loop was cast off, the face of the hook being beveled for that purpose, it was drawn upward by the action of the hook upon the loop through which it was then passing. During the rotation of the hook each loop was passed around a disk bobbin provided with the second thread and serving the part of the shuttle in other machines. The four-motion feed was actuated in this machine by means of a spring bar and a cam in conjunction with the mandrel.

From the beginning, Wheeler and Wilson had looked beyond the use of the sewing machine solely by manufacturers and had seen the demand for a light-running, lightweight machine for sewing in the home. Wilson’s inventions lent themselves to this design, and Wheeler and Wilson led the way to the introduction of the machine as a home appliance. Other manufacturers followed.

When the stock company was formed, Mr. Wilson retired from active participation in the business at his own request. His health had not been good, and a nervous condition made it advisable for him to be freed from the responsibility of daily routine. During this period Wilson’s inventive contributions to the sewing machine continued as noted, and in addition he worked on inventions concerning cotton picking and illuminating gases.

Wheeler and Wilson’s foremost competitor in the early years of sewing-machine manufacture was the Singer Company, which overtook them by 1870 and finally absorbed the entire Wheeler and Wilson Manufacturing Company in 1905.

The founder of this most successful 19th-century company was Isaac Singer, a native of Pittstown, New York. [52] Successively a mechanic, an actor and an inventor, Singer came to Boston in 1850 to promote his invention of a machine for carving printers’ wooden type. He exhibited the carving machine in Orson Phelps’ shop, where the Blodgett and Lerow machines were being manufactured.

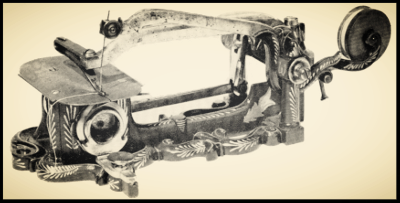

Because the carving machine evoked but little interest, Singer turned his attention to the sewing machine as a device offering considerable opportunity for both improvement and financial reward. Phelps liked Singer’s ideas and joined with George Zieber, the publisher who had been backing the carving-machine venture, to support Singer in the work of improving the sewing machine. His improvements in the Blodgett and Lerow machine included a table to hold the cloth horizontally rather than vertically (this had been used by Bachelder and Wilson also), a yielding vertical presser foot to hold the cloth down as the needle was drawn up, and a vertically reciprocating straight needle driven by a rotary, overhanging shaft.

The story of the invention and first trial of the machine was told by Singer in the course of a patent suit sometime later:

I explained to them how the work was to be fed over the table and under the presser-foot, by a wheel, having short pins on its periphery, projecting through a slot in the table, so that the work would be automatically caught, fed and freed from the pins, in place of attaching and detaching the work to and from the baster plate by hand, as was necessary in the Blodgett machine.

Phelps and Zieber were satisfied that it would work. I had no money. Zieber offered forty dollars to build a model machine. Phelps offered his best endeavors to carry out my plan and make the model in his shop; if successful we were to share equally. I worked at it day and night, sleeping but three or four hours a day out of the twenty-four and eating generally but once a day, as I knew I must make it for the forty dollars or not get it at all.

The machine was completed in eleven days. About nine o’clock in the evening we got the parts together and tried it; it did not sew; the workmen exhausted with almost unremitting work, pronounced it a failure and left me one by one.

Zieber held the lamp and I continued to try the machine, but anxiety and incessant work had made me nervous and I could not get tight stitches. Sick at heart, about midnight, we started for our hotel. On the way we sat down on a pile of boards and Zieber mentioned that the loose loops of thread were on the upper side of the cloth. It flashed upon me that we had forgot to adjust the tension on the needle thread. We went back, adjusted the tension, tried the machine, sewed five stitches perfectly and the thread snapped, but that was enough. At three o’clock the next day the machine was finished. I took it to New York and employed Mr. Charles M. Keller to patent it. It was used as a model in the application for the patent. [53]

The first machine was completed about the last of September 1850. The partners considered naming the machine the “Jenny Lind,” after the Swedish soprano who was then the toast of America. It was reported [54] to have been advertised under that name when the machine was first placed on the market, but the name was soon changed to “Singer’s Perpendicular Action Sewing Machine” or simply the “Singer Sewing Machine”, a name correctly anticipated to achieve a popularity of its own.

According to the contract made by the partners, the hurriedly built first machine was to be sent to the Patent Office with an application in the name of Singer and Phelps. An application was made between the end of September 1850 and March 14, 1851, as Singer refers to it briefly in the application formally filed on April 16, 1851, stating, “My present invention is of improvements on a machine heretofore invented by me and for which an application is now pending.” [55]

Fig. 28 — Singer’s patent model, 1851; a commercial machine was used, bearing the serial number 22.

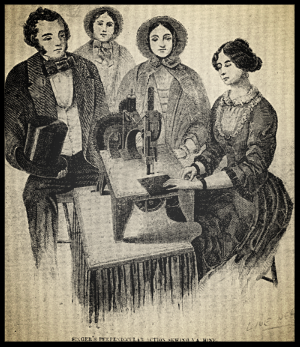

Fig. 29 — Singer’s Perpendicular Action sewing machine, an engraving from Illustrated News, June 25, 1853, which states: “The sewing machine has, within the last two years acquired a wide celebrity and established its character as one of the most efficient labor saving instruments ever introduced to public notice.... We must not forget to call attention to the fact that this instrument is peculiarly calculated for female operatives. They should never allow its use to be monopolized by men.”

In late December 1850 Singer had bought Phelps’ interest in the company. Whether the first application was later abandoned by Singer or whether it was rejected is not known, [56] but a patent on the first application was never issued. The final disposition of this first machine has remained a mystery. [57]

A few machines were manufactured in late 1850 and early 1851 and these attracted considerable attention; orders began to be received in advance of production. The pending patent application did not delay the manufacture and a number of machines were sold before August 12, 1851, when the patent was granted. The patent model is shown in figure 28. [58] It made a lockstitch by means of a straight eye-pointed needle and a reciprocating shuttle. The patent claims, as quoted from the specifications, were as follows:

1. Giving to the shuttle an additional forward motion after it has been stopped to close the loop, as described, for the purpose of drawing the stitch tight, when such additional motion is given at and in combination with the feed motion of the cloth in the reverse direction, and the final upward motion of the needle, as described, so that the two threads shall be drawn tight at the same time, as described.

2. Controlling the thread during the downward motion of the needle by the combination of a friction-pad to prevent the slack above the cloth, with the eye on the needle-carrier for drawing back the thread, for the purposes and in the manner substantially as described.

3. Placing the bobbin from which the needle is supplied with thread on an adjustable arm attached to the frame, substantially as described, when this is combined with the carrying of the said thread through an eye or guide attached to and moving with the needle-carrier, as described, whereby any desired length of thread can be given for the formation of the loop without varying the range of motion of the needle, as described.

The feeding described in the Singer patent was “by the friction surface of a wheel, whose periphery is formed with very fine grooves, the edges of which are slightly serrated, against which the cloth is pressed by a spring plate or pad.” Although claimed by the inventor in the handwritten specifications, it was not allowed as original.

The machines manufactured by the Singer company (fig. 29) were duplicates of the patent model. These machines were quite heavy and intended for manufacturing rather than for family use in the home.

Fig. 30 — I. M. Singer & Co. New York showroom of the mid-1850s, as illustrated in Frank Leslie’s Illustrated Newspaper, August 29, 1857; only manufacturing machines are shown in this illustration.

Fig. 31 — Hunt and Webster’s sewing-machine manufactory exhibition and salesroom in Boston, as illustrated in Ballou’s Pictorial, July 5, 1856; only manufacturing machines are shown.

Singer enjoyed demonstrating the machine and showed it to church and social groups and even at circuses; this personal association then encouraged him to improve its reliability and convenience. He developed a wooden packing case which doubled as a stand for the machine and a treadle to allow it to be operated by foot. Because of the dimensions of the packing case, Singer put the pivot of the treadle toward its center, about where the instep of the foot would rest. This produced the heel-and-toe action treadle, a familiar part of the sewing machine until its replacement by the electric motor. Both hands were freed to guide and arrange the cloth that was being stitched. Singer also added a flywheel to smooth out the treadle action and later an iron stand with a treadle wide enough for both feet. The treadle had been in use for two years before a rival pointed out that it might have been patented. To Singer’s chagrin it was then too late for patent laws did not permit patenting a device that had been in public use.

A new obstacle appeared in the Singer company’s path when Howe demanded $25,000 for infringement of his patent. Singer and Zieber decided to fight, enlisting the legal aid of Edward Clark, a lawyer and financier. Howe’s action was opposed on the basis of Hunt’s machine of 1834, which they stated had anticipated Howe’s invention.

While they were resisting, Howe sued three firms that were using and selling Singer machines. The court order required the selling firms and the purchasers to provide an account of the profits accrued from the sale and the use of the sewing machines and restrained the firms from selling the machines during the pendency of the suit. [59] As a result of this action, a number of Singer’s rivals purchased licenses from Howe and advertised that anyone could sell their machines without fear of a suit. This gave them a great competitive advantage, and Singer and Clark [60] decided it was best to seek a settlement with Howe. On July 1, 1854, they paid him $15,000 and took out a license.

Fig. 32 — Singer’s new Family Sewing Machine, illustration from a brochure dating about 1858 or 1859 which states: “A few months since, we came to the conclusion that the public taste demanded a sewing machine for family purposes more exclusively; a machine of smaller size and of a lighter and more elegant form; a machine decorated in the best style of art, so as to make a beautiful ornament in the parlor or boudoir; a machine very easily operated, and rapid in working.... To supply this public want, we have just produced and are now prepared to receive orders for, ‘Singer’s new Family Sewing Machine.’”

In spite of this defeat, the Singer company could claim several important improvements to the sewing machine and the acquisition of the patents rights to the Morey and Johnson machine of 1849, which gave them control of the spring or curved arm to hold the cloth by a yielding pressure. Although this point had not been claimed in the 1849 patent, the established principle of patent law allowed that a novel device introduced and used in a patented machine could be covered by a reissue at any time during the life of the patent. Upon becoming owners of the Morey and Johnson patent, Singer applied for a reissue which covered this type of yielding pressure. It was granted on June 27, 1854. The Singer company’s acquisition of the Bachelder patent had given them control of the yielding pressure bar also.

Fig. 33 —Singer Family Machine 1858, head only.

Singer’s aggressive selling had begun to overcome the public’s suspicion of sewing machines. He pioneered in the use of lavishly decorated sewing-machine showrooms when the company offices were expanded in the mid-1850s (fig. 30). These were rich with carved walnut furniture, gilded ornaments and carpeted floors, places in which Victorian women were not ashamed to be seen. The machines were demonstrated by pretty young women. The total effect was a new concept of selling and Singer became the drum major of a new and coming industry that had many followers (see fig. 31).

Fig. 34 — Grover and Baker’s patent model, 1851.

The first, light, family sewing machine by the Singer company was not manufactured until 1858 (figs. 32 and 33). Comparatively few of these machines were made as they proved to be too small and light. The men in the shop dubbed the machine “The Grasshopper,” but it was officially called the new Family Sewing Machine or the Family Machine. [61] Because of its shape, Singer company brochures of the 1920s referred to it as the Turtleback Machine.

Since the cost of sewing machines was quite high and the average family income was low, Clark suggested the adoption of the hire-purchase plan. Into the American economy thus came the now-familiar installment buying.

Singer and Clark continued to be partners until 1863 when a corporation was formed. At this time Singer decided to withdraw from active work. He received 40 percent of the stock and retired to Paris and later to England, where he died in 1875.

Fig. 35 — This Grover and Baker cabinet-style sewing machine of 1856 bears the serial number 5675 and the patent dates February 11, 1851, June 22, 1852, February 22, 1853, and May 27, 1856.

By the mid-1850s the basic elements of a successful, practical sewing machine were at hand, but the continuing court litigation over rival patent rights seemed destined to ruin the economics of the new industry. It was then that the lawyer of the Grover and Baker company, another sewing-machine manufacturer of the early 1850s, supplied the solution. Grover and Baker were manufacturing a machine that was mechanically good, for this early period. William O. Grover was another Boston tailor, who, unlike many others, was convinced that the sewing machine was going to revolutionize his chosen trade. Although the sewing machines that he had seen were not very practical, he began in 1849 to experiment with an idea based on a new kind of stitch. His design was for a machine that would take both its threads from spools and eliminate the need to wind one thread upon a bobbin. After much experimenting, he proved that it was possible to make a seam by interlocking two threads in a succession of slipknots, but he found that building a machine to do this was a much more difficult task. It is quite surprising that while he was working on this idea, he did not stumble upon a good method to produce the single-thread (as opposed to Grover and Baker’s two-thread) chainstitch, later worked out by another. Grover was working so intently on the use of two threads that apparently no thought of forming a stitch with one thread had a chance to develop.

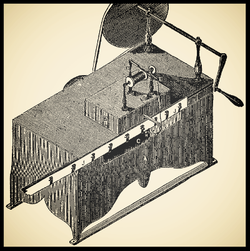

At this time Grover became a partner with another Boston tailor, William E. Baker, and on February 11, 1851, they were issued U.S. patent No. 7,931 for a machine that did exactly what Grover had set out to do; it made a double chainstitch with two threads both carried on ordinary thread spools. The machine (figs. 34 and 35) used a vertical eye-pointed needle for the top thread and a horizontal needle for the underthread. The cloth was placed on the horizontal platform or table, which had a hole for the entry of the vertical needle. When this needle passed through the cloth, it formed a loop on the underside. The horizontal needle passed through this loop forming another loop beyond, which was retained until the redescending vertical needle enchained it, and the process repeated. The slack in the needle thread was controlled by means of a spring guide. The cloth was fed by feeding rolls and a band.

Fig. 36 — Grover’s patent model for the first portable case, 1856. The machine in the case is a commercial machine of 1854, bearing the serial number 3012 and the patent dates “Feby 11, 1851, June 22, 1852, Feby 22, 1853.” Powered by a single, foot-shaped treadle that was connected by a removable wooden pitman, it also could be turned by hand.

A company was organized under the name of Grover and Baker Sewing Machine Company and soon the partners took Jacob Weatherill, mechanic and Orlando B. Potter, lawyer (who became the president), into the firm. Potter contributed his ability as a lawyer in lieu of a financial investment and handled the several succeeding patents of Grover and Baker. These patents were primarily for mechanical improvements such as U.S. patent No. 9,053 issued to Grover and Baker on June 22, 1852, for devising a curved upper needle and an under looper [62] to form the double-looped stitch which became known as the Grover and Baker stitch. One of the more interesting of the patents, however, was for the box or sewing case for which Grover was issued U.S. patent No. 14,956 on May 27, 1856. The inventor stated “that when open the box shall constitute the bed for the machine to be operated upon, and hanging the machine thereto to facilitate oiling, cleansing, and repairs without removing it from the box.” It was the first portable sewing machine (fig. 36).

Though the Grover and Baker company manufactured machines using a shuttle and producing the more common lockstitch, both under royalty in their own name and also for other smaller companies, Potter was convinced that the Grover and Baker stitch was the one that eventually would be used in both family and commercial machines. He, as president, directed the efforts of the company to that end. When the basic patents held by the “Sewing-Machine Combination” (discussed on pp. 41-42) began to run out in the mid-1870s, dissolving its purpose and lowering the selling price of sewing machines, the Grover and Baker company began a systematic curtailing of expenses and closing of branch offices. All the patents held by the company and the business itself were sold to another company. [63] But the members of the Grover and Baker company fared well financially by the strategic move.

The Grover and Baker machine and its unique stitch did not have a great influence on the overall development of the mechanics of machine sewing. The merits of a double-looped stitch—its elasticity and the taking of both threads from commercial spools—were outweighed by the bulkiness of the seam and its consumption of three times as much thread as the lockstitch required. Machines making a similar type of stitch have continued in limited use in the manufacture of knit goods and other products requiring an elastic seam. But, more importantly, Grover and Baker’s astute Orlando B. Potter placed their names in the annals of sewing-machine history by his work in forming the “Combination,”believed to be the first “trust” of any prominence.

back to Chapter One

FOOTNOTES [?]

source by

SMITHSONIAN INSTITUTION

UNITED STATES NATIONAL MUSEUM

As reproduction of historical newspaper articles and/or historical sources and/or historical artifacts, this works may contain errors of spelling and/or missing words and/or missing pages and/or poor pictures, etc.