- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

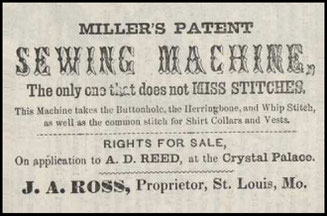

Charles Miller

At the time of his patent, Charles Miller lived in St. Louis, Missouri, an uncommon choice of residence for a sewing machine inventor. Most of the inventors and subsequent manufacturers, were located in the northeastern United States, particularly New York, Massachusetts and Connecticut. In his patent specification, Miller states: “This invention relates to that description of sewing machine which forms the stitch by the interlacing of two threads, one of which is passed through the cloth in the form of a loop and the other carried by a shuttle through the said loop”. His claim continues by stating: “It consists, first, in an improved stop-motion, or certain means of preventing the feed or movement of the cloth when by accident the thread breaks or catches in the seam and, second, in certain means of sewing or making a stitch similar to what is termed in hand-sewing the back stitch”. According to Miller, his mechanism was different in that it passed the needle through the cloth in two places rather than in one, as was the case with other sewing machines of the time. His brass model is strikingly handsome and engraved on the base of the model is “Charles Miller & J. A. Ross”. Usually when a second name is so prominently displayed on a model, it indicates a second inventor. However, no mention is made of Ross in the patent specification (US 9.139 issued on July 20, 1852).

Jonathan A. Ross the following year at the 1853 New York Exhibition, exhibited a sewing machine alongside of Wilson's and Singer's and is the only one which, by a transverse motion of the cloth feed-roller, attempts to sew button holes. Mr. J. A. Ross is listed in the catalogue as a sewing machine manufacturer from St. Louis, Missouri.

An application was made for the improvement in the transverse button hole stitch. J. A. Ross was the assignee of this patent. It was the first sewing machine patented to stitch button holes (US 10.609, issued March 7, 1854). In his patent specification, Miller describes the three different stitches, “button-hole stitch, whip stitch or herring-bone stitch”, that can be mechanically sewn to finish the buttonhole.

Charles Miller's Sewing Machines

from The Sewing Machine Times (1910)

As no one has given any information on the subject of a card here shown, Sewing Machine Times will now give what it is in possession of and leave the offer a $ still open for a few months for the best of anything further that can be added. Charles Miller, of St. Louis, Missouri, invented three sewing machines, each distinctive in construction and subject of a separate patent:

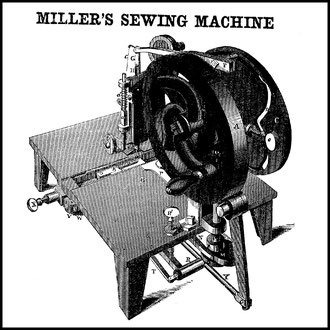

The machine of the 1854 patent, which was assigned to J. A. Ross, also of St. Louis, was exhibited the previous year at the New York Crystal Palace (July 1853) along with Singer's and Wheeler & Wilson's. This was a large, heavy shuttle machine, hand-driven, the work fed by a revolving drum with rolling presser. The drum was arranged for a lateral movement when desired to make a zig-zag stitch. The needle bar was actuated by a cam as in early Howe machine, through a walking beam.

Miller's first machine was still more heavy and cumbersome. This, like the other, could zig-zag; it also made a back stitch, going back as in hand backstitching half the length of the previous stitch. This back stitch was made by passing the needle through a bend of the fabric, coming out on the same side of the fabric that it entered, the feed being half the length of the bend. For regular lockstitch the fabric was not bent.

"The Cumbersome Machine"